Introduction

In the world of precision manufacturing, understanding the cost of laser cutting machines is essential for making sound investment decisions. Whether you're looking to enhance your production capabilities or dive into the realm of artistry with a laser carving machine, knowing what you're getting into can save you time and money. With various options available, it's crucial to navigate through the features and specifications that best suit your needs.

Exploring the Cost of Laser Cutting Machines

The cost of laser cutting machines varies widely based on several factors including technology type, features, and brand reputation. For instance, a basic metal cutter machine might be more affordable than advanced models like fiber laser engravers that offer superior precision and speed. By understanding these variables, potential buyers can better assess what fits their budget while still meeting their operational requirements.

Why Invest in a Laser Carving Machine

Investing in a laser carving machine opens up new avenues for creativity and efficiency in production processes. These machines not only provide intricate designs but also significantly reduce material waste compared to traditional methods. Additionally, the versatility of a metal cutting machine laser allows businesses to expand their service offerings by tackling diverse projects ranging from simple cuts to elaborate engravings.

How to Choose the Right Machine

Choosing the right machine involves evaluating your specific needs against what different models offer in terms of functionality and price point. Considerations should include the types of materials you plan to work with, thickness limits, and whether you need portability or advanced automation features in your metal laser cutter. By carefully weighing these factors alongside budget constraints related to the cost of laser cutting machines, you'll be well-equipped to make an informed decision.

Understanding the Basics of Laser Cutting

Laser cutting has revolutionized the manufacturing and design industries, providing precision and efficiency that traditional methods struggle to match. At its core, laser cutting involves using a focused beam of light to cut through various materials, including metals, wood, and plastics. This technology not only enhances production speed but also reduces waste, making it a cost-effective solution for businesses looking to invest in laser machines.

What is a Laser Cutting Machine

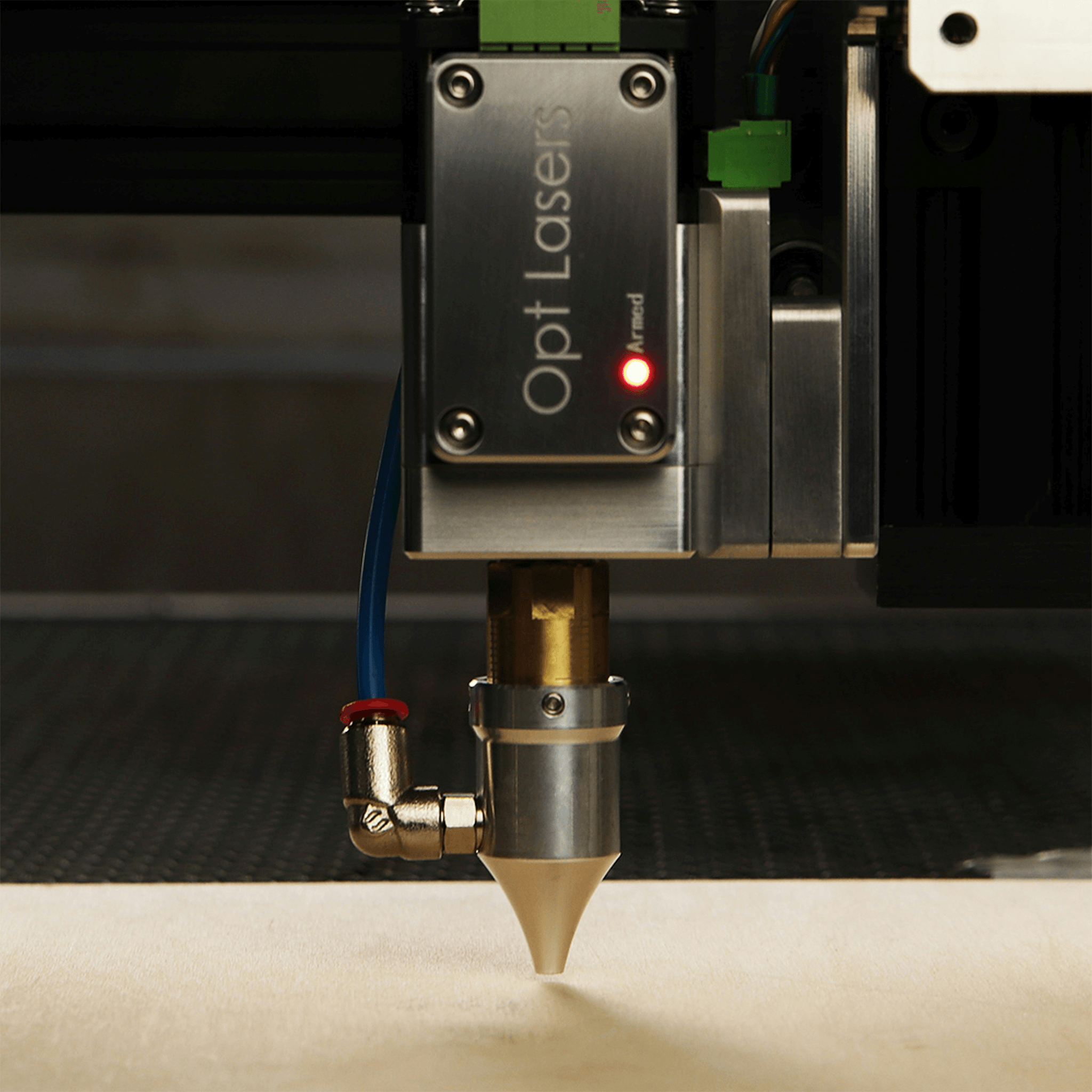

A laser cutting machine utilizes a high-powered laser beam to slice through materials with remarkable accuracy. The process begins with the machine directing the laser onto the surface of the material, which melts or vaporizes it away as it moves along predefined paths. The beauty of a metal cutter machine lies in its ability to create intricate designs that would be nearly impossible with conventional cutting tools.

For those considering investing in this technology, understanding the cost of laser cutting machines is crucial. Prices can vary significantly based on features and capabilities, but investing in a quality laser metal cutting machine can yield substantial returns through increased productivity and reduced material waste. Whether you’re looking for a compact fiber laser engraver or an industrial-grade model, knowing what constitutes value will help you make informed decisions.

Different Types of Laser Cutters

When exploring options for a laser carving machine, it's essential to recognize that not all cutters are created equal; they come in various types tailored for specific applications. CO2 lasers are popular for non-metal materials like wood and acrylics due to their versatility and lower operating costs. In contrast, fiber lasers excel at cutting metals thanks to their high energy efficiency and ability to handle thicker materials effectively.

Another option is the solid-state laser cutter which combines elements from both CO2 and fiber technologies but usually comes at a higher price point due to its advanced capabilities. Each type has unique strengths that cater to different business needs; thus understanding these distinctions will guide you toward selecting the best metal cutting machine laser for your projects. Ultimately, choosing between these diverse types hinges on your specific requirements and budget considerations.

Applications for Metal Cutting Machines

The applications for metal cutting machines extend far beyond simple fabrication; they play pivotal roles across numerous industries including automotive, aerospace, jewelry making, and more. From creating custom parts for machinery to crafting intricate artistic designs in metalwork, these machines offer unparalleled flexibility in production processes. Moreover, as industries increasingly adopt automation technologies, utilizing advanced metal laser cutters allows businesses to stay competitive by enhancing operational efficiency.

A well-chosen metal cutter machine can streamline workflows while producing high-quality components with minimal human intervention required—saving both time and labor costs in the long run. Investing in such technology not only improves output quality but also opens doors for innovative product designs previously thought unattainable without extensive manual labor or costly rework processes. As you navigate your options among various models available on the market today, consider how each application aligns with your business goals.

Factors Influencing the Cost of Laser Cutting Machines

When diving into the world of laser cutting machines, understanding the factors that influence their cost is crucial. The price tag attached to a laser carving machine can vary widely based on several key elements. These factors include the types and thickness of materials being cut, machine specifications and features, and the reputation of the brand or manufacturer.

Material Types and Thickness

The cost of a laser cutting machine is heavily influenced by the types of materials you plan to work with. Different materials, such as stainless steel, aluminum, or acrylic, require varying amounts of power and precision from a metal laser cutter. Thicker materials will generally demand more robust machines with higher wattage capabilities, which can significantly increase your investment in a metal cutting machine laser.

Additionally, if you’re looking into a fiber laser engraver for intricate designs on thick metals, be prepared to pay more for specialized equipment. The versatility offered by some machines allows them to handle multiple material types efficiently; however, this flexibility often comes at a premium price point. Ultimately, knowing your material requirements will help you gauge how much you should expect to spend on your ideal laser metal cutting machine.

Machine Specifications and Features

When comparing different models of metal cutter machines, specifications play a pivotal role in determining their cost. Advanced features like higher wattage lasers for faster cutting speeds or enhanced cooling systems can elevate the price considerably but may also improve efficiency in production settings. Features such as automation capabilities or integrated software for design processing further contribute to both functionality and overall costs.

Moreover, additional attributes like bed size and focusing optics are essential considerations that can impact your choice between budget-friendly options or high-end models. If you're investing in a professional-grade laser machine for extensive use in commercial applications, these specifications become even more critical as they reflect not just performance but also long-term value. Ultimately, understanding what each specification brings to the table will empower you to make an informed decision about which metal cutting machine best fits your needs without breaking the bank.

Brand Reputation and Manufacturer

The brand reputation plays an undeniable role in influencing the cost of laser cutting machines available on the market today. Established manufacturers often command higher prices due to their track record for reliability and customer service support; after all, no one wants buyer's remorse when investing in a costly piece of equipment like a laser carving machine! Investing in well-known brands may come with peace of mind regarding quality assurance but could stretch your budget tighter than anticipated.

On the flip side, lesser-known brands may offer competitive pricing on their products but might lack comprehensive customer support or warranty coverage that reputable manufacturers provide. It's essential to weigh these factors carefully—after all, saving money upfront could lead to more expenses down the road if issues arise with your new metal laser cutter! Researching reviews and case studies related to specific brands helps illuminate whether you're getting value for money spent on your selected model.

Affordable Options in the Market

When it comes to investing in a laser cutting machine, understanding your budget is crucial. The market offers a range of options that cater to different financial capabilities without compromising on quality. Whether you're looking for a budget-friendly laser metal cutting machine or a premium model, there's something for everyone.

Budget-Friendly Laser Metal Cutting Machines

For those just starting out or operating on a tight budget, there are several cost-effective laser metal cutting machines available that deliver impressive performance without breaking the bank. These machines typically utilize CO2 technology, making them ideal for cutting softer materials like acrylic and wood while still offering decent capabilities for thin metals. While they may not have all the bells and whistles of more expensive models, they provide excellent value for hobbyists and small businesses looking to dip their toes into the world of metal fabrication.

One standout option in this category is the entry-level fiber laser engraver, which combines affordability with efficiency. These machines are compact and easy to use, making them perfect for workshops with limited space or those just starting their journey into laser carving. With prices often under $5,000, these budget-friendly models can help you explore various applications without overwhelming your finances.

Mid-Range Choices for Small Businesses

If you're ready to take your operations up a notch but don’t want to go all-in on a premium model just yet, mid-range laser cutters offer an attractive balance between cost and features. Typically priced between $5,000 and $15,000, these metal cutter machines come equipped with advanced functionalities such as higher wattage options and better software compatibility that can significantly enhance productivity.

These machines are particularly suited for small businesses that require versatility in their projects—think intricate designs or thicker materials. Investing in one of these mid-range machines can yield significant returns by increasing efficiency and reducing production time while maintaining quality cuts across various materials.

Premium Machines Worth the Investment

For established businesses aiming for top-tier performance and durability, investing in premium laser cutting machines is often worth every penny spent. These high-end models offer advanced features like automated settings, superior cooling systems, and enhanced precision controls that make them ideal for heavy-duty applications involving thick metals or complex designs.

While the cost of these premium metal cutting machine lasers can range from $15,000 to over $100,000 depending on specifications and brand reputation, they often come with warranties that ensure longevity and reliability—an essential consideration when weighing investment returns. Companies utilizing high-quality equipment frequently report lower operational costs over time due to reduced maintenance needs and enhanced productivity levels.

The Role of Kiant Machinery

In the competitive landscape of laser cutting technology, Kiant Machinery stands out for its commitment to innovation and quality. They offer a range of machines that cater to various needs, from hobbyists seeking a laser carving machine to industrial users requiring robust metal cutting machines. Understanding the advanced features of Kiant's offerings can help potential buyers assess their investment in a cost-effective manner.

Advanced Features of Kiant's Laser Machines

Kiant's laser machines are equipped with state-of-the-art technology designed to enhance precision and efficiency in metal cutting. Their fiber laser engraver models boast high-speed processing capabilities, allowing for intricate designs without compromising on speed—perfect for busy workshops needing reliable performance from their metal cutter machines. Additionally, many models come with customizable settings that allow users to adjust power levels according to the material type and thickness, ensuring optimal results across various applications.

Moreover, the durability of Kiant’s equipment is noteworthy; built with high-quality materials, these machines are designed for long-term use while minimizing maintenance costs associated with cheaper alternatives. This focus on longevity makes investing in a Kiant metal cutting machine laser not just about immediate needs but also about future savings on repairs and replacements. With user-friendly interfaces and advanced software integration, even those new to operating a laser machine will find it intuitive and straightforward.

Customer Support and Training Services

Kiant Machinery takes pride in offering exceptional customer support that extends well beyond the point of sale. Their team provides comprehensive training services that ensure users can effectively operate their new laser carving machine right out of the box—no more fumbling around trying to figure things out! This commitment to customer education means clients can maximize their investment by understanding how best to utilize their metal laser cutter from day one.

Additionally, Kiant offers ongoing support through troubleshooting assistance and regular updates on software enhancements or new features available for existing machines. This level of dedication not only helps customers feel confident in using their equipment but also fosters long-lasting relationships between clients and the manufacturer—a win-win situation! With such robust support structures in place, buyers can rest assured they are making an informed decision when considering the cost of a laser cutting machine.

Case Studies of Successful Implementations

The effectiveness of Kiant’s machinery is best illustrated through real-world case studies showcasing successful implementations across diverse industries. For instance, one small business specializing in custom signage reported increased productivity after upgrading to a Kiant fiber laser engraver—allowing them to take on larger projects without sacrificing quality or timelines. Such success stories highlight how investing in a reliable metal cutting machine can lead not only to improved operational efficiency but also increased profitability over time.

Another case study involved an automotive parts manufacturer who integrated multiple Kiant metal cutter machines into their production line; this resulted in significant reductions in waste material due to precise cuts made possible by advanced technology features unique to these devices. By analyzing these examples, potential buyers can see firsthand how choosing the right equipment impacts overall business performance while providing a clear perspective on what constitutes good value versus excessive costs associated with inferior options available elsewhere.

Comparing Costs: Buying vs. Leasing

When it comes to acquiring a laser cutting machine, one of the biggest decisions you’ll face is whether to buy or lease. Each option has its own set of advantages and disadvantages that can significantly impact your bottom line. Understanding these nuances is crucial for making an informed decision about the cost of laser cutting machines.

Pros and Cons of Buying a Laser Machine

Buying a laser carving machine offers several benefits, including ownership and potential long-term savings. Once the initial investment is made, you won’t have to worry about ongoing lease payments, which can free up cash flow for other business expenses. However, the upfront cost of a high-quality metal cutting machine laser can be daunting; it often requires a substantial financial commitment that may not be feasible for all businesses.

On the downside, owning a metal cutter machine means you are responsible for maintenance and repairs, which can add to your overall costs over time. Additionally, technology evolves rapidly in this field; owning an older model may limit your capabilities compared to newer fiber laser engravers on the market. Therefore, while buying provides control and potential savings in the long run, it also comes with risks that should not be overlooked.

When Leasing Makes Financial Sense

Leasing a metal laser cutter can be an attractive option for businesses looking to minimize upfront costs while still benefiting from advanced technology. This approach allows companies to access high-end equipment without breaking the bank—perfect for startups or small businesses with tight budgets. Moreover, leasing agreements typically include maintenance services, alleviating concerns about unexpected repair costs associated with ownership.

Another advantage of leasing is flexibility; if your business needs change or if technology advances rapidly (as it often does), you have the option to upgrade your equipment at the end of the lease term without being stuck with outdated machinery. This adaptability makes leasing particularly appealing in industries where innovation drives competitiveness. However, it's essential to weigh these benefits against potential long-term costs—over time, leases may add up more than buying outright.

Long-Term Projections for Investment Returns

When evaluating whether to buy or lease a laser machine, consider how each option aligns with your long-term financial goals and return on investment (ROI). If you plan on using a metal cutting machine laser extensively over many years, purchasing might yield better returns as you'll eventually eliminate monthly payments after covering initial expenses. In contrast, if you anticipate fluctuating demand or project-based work that requires flexibility in equipment use, leasing could provide better short-term ROI by allowing access to state-of-the-art technology without significant financial strain.

It's also worth considering depreciation when buying; while your asset will lose value over time due to wear and tear or technological obsolescence, this factor can sometimes be offset by tax deductions available on purchased equipment. Conversely, leased machines typically do not provide such tax benefits since they are considered operational expenses rather than capital investments. Ultimately, conducting thorough financial analysis tailored specifically for your business scenario will guide you toward making decisions that optimize both immediate cash flow and long-term profitability.

Conclusion

In the ever-evolving world of manufacturing, making informed decisions about your equipment is crucial, especially when it comes to the cost of laser cutting machines. Investing in a laser carving machine can significantly enhance your production capabilities and efficiency. By understanding the various factors that influence pricing and functionality, you can choose a metal cutting machine laser that meets your specific needs without breaking the bank.

Making Informed Decisions on Laser Machines

When selecting a laser metal cutting machine, it's essential to weigh your options carefully. Consider not only the upfront cost but also long-term operational expenses and potential returns on investment. Whether you're leaning towards a budget-friendly option or contemplating a premium metal cutter machine, thorough research will empower you to make choices that align with your business goals.

Key Takeaways on Cost and Value

The cost of laser cutting machines varies widely based on specifications, features, and brand reputation. Remember that investing in quality often pays off in durability and performance; cheaper options may lead to higher maintenance costs down the line. Ultimately, understanding what you need from a fiber laser engraver or other types of machines will guide you toward maximizing value while minimizing unnecessary expenditures.

Next Steps for Your Laser Cutting Journey

Now that you've gathered insights into the world of laser technology, it’s time to take action! Start by analyzing your production requirements and budget constraints to narrow down your options effectively. Reach out to manufacturers or suppliers for demonstrations or further information about their offerings—this will not only clarify costs but also help you visualize how each metal cutting machine fits into your operations.