Introduction

In today's fast-paced manufacturing landscape, the rise of laser cutting technology has revolutionized how industries approach precision and efficiency. As a leading laser cutting machine manufacturer, Kiant Machinery stands at the forefront of this innovation, providing cutting-edge solutions that cater to diverse metalworking needs. With an array of options available, understanding what laser cutting machines can offer is crucial for any business looking to enhance productivity.

The Rise of Laser Cutting Technology

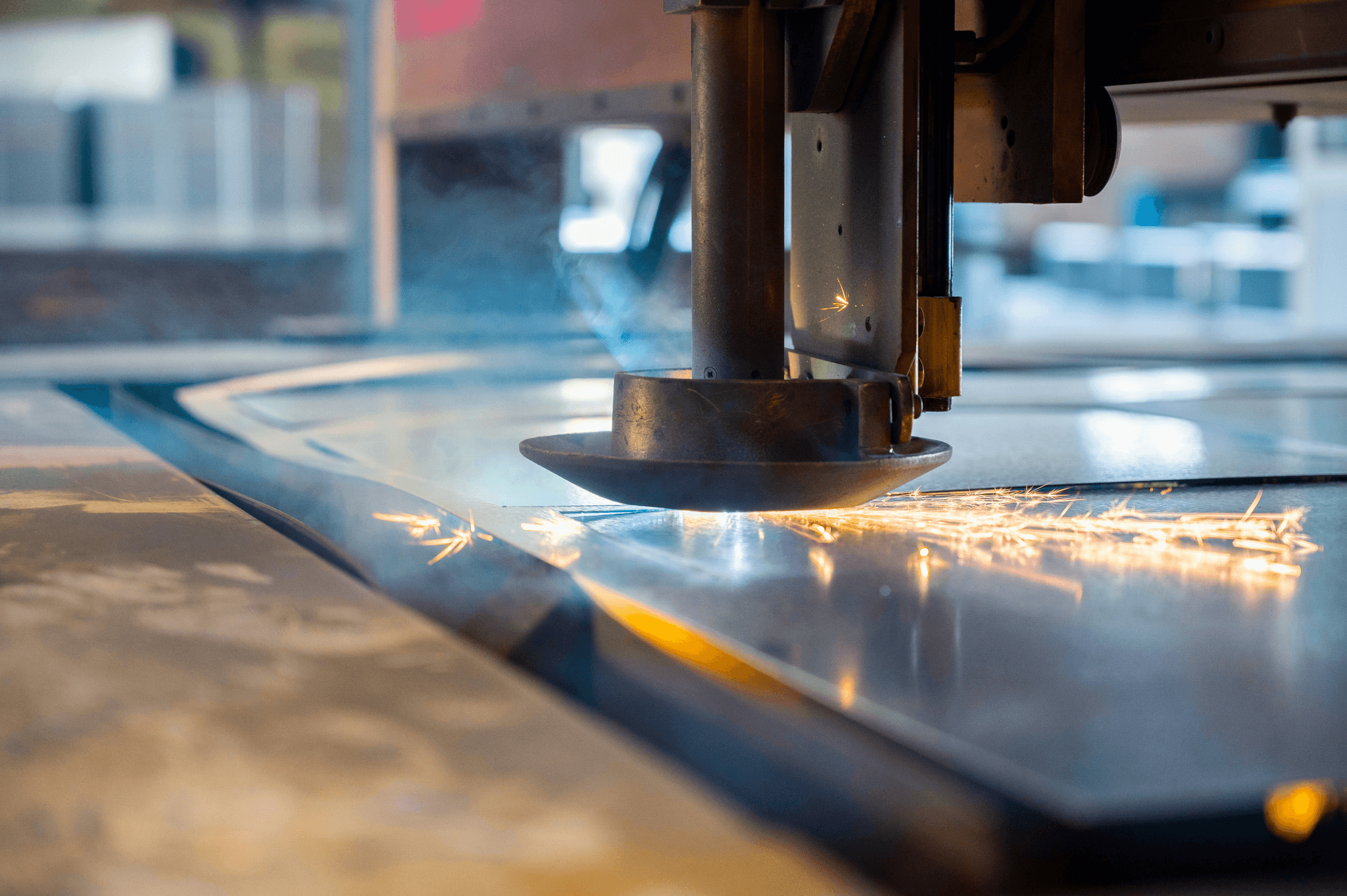

The emergence of laser technology has transformed metal fabrication processes, allowing for intricate designs and high-speed production that traditional methods simply cannot match. As industries demand more precision and versatility, the popularity of metal cutting laser cutters has surged, making them essential tools in modern workshops. This evolution in manufacturing not only boosts efficiency but also significantly reduces waste and operational costs.

Why Choose Kiant Machinery

Kiant Machinery distinguishes itself as a premier choice among laser machine providers due to its commitment to quality, innovation, and customer satisfaction. Their range of fiber lasers is designed with advanced features that ensure optimal performance for various applications in metal cutting machinery. When you choose Kiant Machinery as your partner in production, you're investing in reliable technology backed by exceptional support.

Overview of Laser Cutting Machines

Laser cutting machines employ focused beams of light to slice through materials with unparalleled accuracy and speed, making them ideal for a variety of applications from automotive to aerospace. These machines come in different types—each tailored for specific tasks—such as CO2 lasers for non-metal materials and fiber lasers specifically designed for metals. Understanding the capabilities and advantages offered by these metal laser cutters can empower businesses to make informed decisions about their manufacturing processes.

Understanding Laser Cutting Machines

Laser cutting machines have revolutionized the manufacturing landscape, offering precision and efficiency that traditional methods simply can't match. These advanced tools utilize focused laser beams to slice through various materials, particularly metals, with incredible accuracy. For anyone considering a metal cutting laser cutter, understanding the fundamentals of how these machines operate is crucial for making informed decisions.

What is a Laser Cutting Machine?

A laser cutting machine is a high-tech device that employs concentrated beams of light to cut through materials, primarily metals. The process involves directing a powerful laser beam onto the material's surface, which melts or vaporizes it in a precise manner. This technology has emerged as a game-changer in industries ranging from automotive to aerospace, where precision and speed are paramount.

The versatility of these machines means they can handle various thicknesses and types of metal, making them essential for any modern workshop. Whether you're looking at fiber lasers or CO2 lasers, each type has its unique strengths tailored for specific applications. When investing in a metal cutting machine laser, understanding your specific needs will help you choose the best option available.

Types of Laser Cutting Technology

There are several types of laser cutting technology available today, each designed to meet different manufacturing needs. The most common types include CO2 lasers and fiber lasers; both have their own advantages depending on the material being processed. Fiber lasers are particularly popular among metal cutting laser cutter enthusiasts due to their high efficiency and ability to cut through thicker materials with ease.

CO2 lasers excel at cutting non-metal materials like wood or plastics but may not be as effective for heavy-duty metal applications compared to their fiber counterparts. Additionally, there are solid-state lasers which offer another alternative based on specific requirements like power output and speed. Understanding these different technologies can help you identify which type aligns best with your production goals.

Advantages of Using Laser Machinery

Choosing laser machinery over traditional methods comes with numerous benefits that can significantly enhance your production capabilities. First and foremost is precision; laser cutting machines can achieve tolerances within just a few microns—something that's hard to replicate with mechanical means. This level of accuracy reduces waste and improves overall product quality.

Another significant advantage is speed; metal cutting machines equipped with advanced laser technology can operate much faster than conventional methods without sacrificing quality or detail. This efficiency translates into cost savings over time as you maximize output while minimizing labor costs associated with manual processes. Lastly, investing in a reliable laser cutting machine manufacturer ensures you're getting top-notch support and access to innovative solutions tailored for your unique needs.

Kiant Machinery: A Leader in Innovation

When it comes to laser cutting technology, Kiant Machinery stands out as a beacon of innovation and excellence. As a leading laser cutting machine manufacturer, we harness the power of advanced engineering to create machines that redefine precision and efficiency in metal fabrication. Our commitment to pushing the boundaries of what's possible ensures that our customers always have access to the latest in fiber laser solutions.

Cutting-Edge Fiber Laser Solutions

Kiant Machinery specializes in cutting-edge fiber laser technology, which is revolutionizing the way industries approach metal cutting. Our metal laser cutter systems are designed for unmatched speed and accuracy, allowing businesses to produce intricate designs with ease. The use of fiber lasers not only enhances performance but also reduces operational costs, making them an ideal choice for any modern manufacturing setup.

Our fiber laser solutions are equipped with state-of-the-art features that ensure optimal performance across various applications. Whether you're looking for a compact model or a large-scale production unit, our range of metal cutting machines is tailored to meet diverse needs. With Kiant's focus on innovation, you can trust that our products will keep your business ahead of the competition.

Customization Options for Metal Cutting

At Kiant Machinery, we understand that one size does not fit all when it comes to metal cutting machinery. That's why we offer extensive customization options for our metal cutting laser cutters, ensuring each machine aligns perfectly with your specific requirements. From adjustable power settings to specialized software integrations, our flexibility allows you to optimize your workflow and enhance productivity.

Our team works closely with clients to design bespoke solutions that cater directly to their operational needs and production goals. This level of customization not only maximizes efficiency but also empowers businesses to tackle unique challenges in their respective industries effectively. Investing in a tailored solution from a trusted laser machine manufacturer like Kiant means investing in your future success.

Commitment to Quality and Performance

Quality is at the heart of everything we do at Kiant Machinery; it's what sets us apart as a leading manufacturer in the industry. Each metal cutting machine laser undergoes rigorous testing and quality assurance processes before it reaches our clients' hands, ensuring top-notch performance every time you operate it. Our commitment doesn't stop at delivering exceptional products; we strive for continuous improvement based on customer feedback and technological advancements.

Moreover, we believe that investing in high-quality machinery should come with peace of mind regarding reliability and support. That’s why Kiant Machinery provides comprehensive warranties and after-sales service designed specifically for our machines' longevity and optimal operation—because your success is our priority! By choosing us as your partner in innovation, you're not just acquiring equipment; you're gaining access to years of expertise backed by unwavering dedication.

Applications of Metal Laser Cutters

Laser cutting technology has revolutionized various industries, making it an essential tool for precision and efficiency in metal fabrication. The versatility of metal laser cutters allows them to be used in a wide range of applications, from automotive manufacturing to aerospace components. As businesses seek to enhance their production capabilities, the demand for advanced laser machinery continues to rise.

Industries That Benefit from Laser Cutting

Several industries are reaping the rewards of integrating metal cutting laser cutters into their operations. The automotive sector heavily relies on these machines for creating intricate parts with high precision and minimal waste. Similarly, the aerospace industry utilizes fiber laser technology to manufacture lightweight yet durable components that meet stringent safety standards.

In addition to automotive and aerospace, the construction industry also benefits significantly from metal cutting machines laser. They are used for fabricating structural steel and custom architectural elements that require both strength and aesthetic appeal. Furthermore, electronics manufacturers employ laser machinery for producing circuit boards and enclosures with exact specifications.

The medical device industry is another area where a laser cutting machine manufacturer can make a significant impact. Precision is paramount in this field; thus, metal laser cutters are employed to create surgical instruments and implants that must adhere to strict regulatory standards. Overall, the adaptability of these machines makes them invaluable across various sectors.

Precision and Speed in Production

One of the standout features of using a metal cutting machine laser is its ability to deliver unmatched precision at high speeds. Unlike traditional methods that may produce rough edges or require extensive finishing work, modern fiber lasers can cut through materials with incredible accuracy, ensuring clean lines every time. This level of precision not only enhances the quality of finished products but also reduces material waste.

Moreover, speed is critical in today's fast-paced manufacturing environment; businesses need to meet tight deadlines without compromising quality. Laser machines excel in this regard by significantly reducing production times while maintaining consistent results across multiple runs. This capability allows companies to keep up with market demands while optimizing their operational efficiency.

Investing in a metal laser cutter means embracing both speed and accuracy—two qualities that are essential for staying competitive in any industry today. As manufacturing processes continue evolving toward automation and smart technologies, incorporating such advanced equipment becomes increasingly important for long-term success.

Cost Efficiency with Metal Cutting Machines

Cost efficiency is often at the forefront when businesses consider investing in new equipment like cutting machine lasers or other types of machinery. Laser cutting offers significant savings over time due to reduced material waste—thanks to its precise cuts—and lower labor costs associated with less manual handling required during production processes. These factors contribute directly to improved profit margins over time.

Additionally, maintenance costs tend to be lower compared with other traditional methods since modern fiber lasers have fewer moving parts than mechanical cutters or saws do; this translates into less downtime during operations as well as fewer repairs needed overall! Furthermore, energy consumption tends to be more efficient with advanced lasers versus older technologies—a factor increasingly important given rising energy prices globally.

Ultimately, choosing a reliable laser cutting machine manufacturer ensures you’re investing wisely by obtaining quality equipment designed for longevity while maximizing your return on investment (ROI). By carefully considering all aspects—from initial purchase price through ongoing operational costs—businesses can harness the full potential offered by state-of-the-art metal cutting technology!

The Buying Guide for Laser Cutting Equipment

When it comes to investing in a laser cutting machine, the decision can feel overwhelming. With various options available in the market, knowing what to look for can simplify your search. This guide will help you navigate through essential features, comparisons of different metal cutting lasers, and tips on evaluating a laser cutting machine manufacturer.

Key Features to Consider

Before purchasing a metal cutting laser cutter, it’s crucial to identify the key features that will meet your specific needs. First and foremost is the power output; higher wattage typically translates to faster cutting speeds and the ability to handle thicker materials. Additionally, consider the size of the cutting area; larger workspaces allow for more extensive projects without needing frequent repositioning.

Another important feature is the type of laser technology used—fiber lasers are known for their efficiency and precision in metal applications. Look for machines that offer advanced cooling systems as well; effective cooling can prolong the lifespan of your equipment and maintain optimal performance during long runs. Finally, ensure that your chosen metal cutting machine laser has user-friendly software integration options to streamline operations.

Comparing Different Metal Cutting Lasers

When comparing different metal laser cutters, it's essential to evaluate their specifications side by side. Start by analyzing their speed and accuracy ratings; these metrics are critical for enhancing productivity in any manufacturing environment. Don't forget to check out customer reviews or case studies related to specific models—real-world experiences can provide valuable insights into performance reliability.

Also, consider maintenance requirements when comparing machines; some models may demand more upkeep than others due to design complexity or usage intensity. Explore warranty offerings as well; a robust warranty often indicates a confident manufacturer who stands by their product quality and durability. Lastly, factor in any additional costs such as installation fees or training sessions needed for staff on new machinery.

How to Evaluate a Laser Cutting Machine Manufacturer

Choosing the right laser cutting machine manufacturer is just as vital as selecting the right equipment itself. Start by researching their reputation within the industry—look for manufacturers with extensive experience and positive feedback from existing customers regarding their metal cutting machines' performance. A reputable manufacturer should also have clear information about their production processes and quality control measures.

Next, assess their customer service capabilities; excellent after-sales support is crucial when dealing with high-tech machinery like fiber lasers or other types of laser machinery. Consider whether they offer training programs or resources that help you maximize your investment's potential once you've made your purchase decision. Finally, don't shy away from reaching out directly with questions—it’s an excellent way to gauge responsiveness and expertise before committing.

After-Sales Support and Training

When investing in a laser cutting machine, the journey doesn't end with the purchase. Ensuring optimal use of your laser machinery is crucial for maximizing productivity and maintaining quality. That's why after-sales support and training are essential components of any reputable metal cutting laser cutter manufacturer’s offerings.

Ensuring Optimal Use of Your Laser Machine

To get the most out of your metal cutting machine laser, proper training is vital. Kiant Machinery provides comprehensive training programs tailored to your specific model, ensuring that your operators are well-versed in all features, from basic operation to advanced techniques. This not only boosts efficiency but also minimizes downtime, allowing you to take full advantage of your investment in a fiber laser.

Moreover, ongoing support helps troubleshoot any issues that may arise during operation. With expert guidance and resources readily available, you can ensure that your cutting machine laser remains in peak condition. Ultimately, this commitment to optimal use translates into better performance and longer life for your equipment.

Kiant Machinery's Customer Service Commitment

Kiant Machinery prides itself on its customer service commitment as a leading laser cutting machine manufacturer. From the moment you make contact until long after installation, our team is dedicated to providing personalized assistance tailored to your needs. Whether it's answering questions about maintenance or providing technical support for complex operations, we’re here for you every step of the way.

Our customer service representatives are trained extensively in both our products and industry standards, enabling them to provide informed solutions quickly and effectively. This dedication ensures that when you invest in a metal laser cutter or any other piece of equipment from us, you're never left hanging if problems arise or questions come up later on.

Continuous Learning for Continued Success

In an ever-evolving industry like metal fabrication, continuous learning is key to staying ahead of the competition with your metal cutting machines. Kiant Machinery offers regular workshops and webinars focused on the latest advancements in fiber lasers and best practices for using your equipment effectively. By participating in these sessions, operators can refine their skills and discover new techniques that enhance productivity.

Furthermore, we encourage feedback from our customers about their experiences with our machines so we can continuously improve our offerings and support services. This collaborative approach helps ensure that when you choose a metal cutting machine laser from Kiant Machinery, you're not just buying equipment; you're entering into a partnership aimed at fostering innovation and success together.

Conclusion

In the rapidly evolving world of manufacturing, embracing advanced technologies like laser cutting machines can significantly enhance operational efficiency and product quality. By integrating a metal cutting laser cutter into your production line, you unlock the potential for precision and versatility that traditional methods simply can't match. Choosing the right laser machine is crucial to maximizing your manufacturing capabilities and staying ahead of the competition.

Unlocking Your Manufacturing Potential

Investing in a state-of-the-art metal cutting machine laser can revolutionize your production processes. With features like speed, accuracy, and flexibility, a fiber laser can handle various materials with ease, allowing you to expand your offerings without compromising on quality. As a leading laser cutting machine manufacturer, Kiant Machinery provides solutions that empower businesses to reach new heights in productivity and innovation.

The Future of Laser Cutting Technology

The future of manufacturing is bright with advancements in laser technology on the horizon. Emerging innovations promise even greater efficiencies and capabilities for metal laser cutters, making them indispensable tools for industries worldwide. As we look ahead, it's clear that investing in modern cutting machine lasers will be key to thriving in an increasingly competitive landscape.

Partnering with Kiant Machinery for Success

Our commitment to quality ensures that every metal cutting laser cutter we produce meets stringent performance standards while offering customization options tailored to your specific needs. By choosing us as your trusted laser cutting machine manufacturer, you're not just purchasing equipment; you're investing in long-term success and growth.