Introduction

In the world of manufacturing and fabrication, choosing the right technology can make all the difference in efficiency, cost-effectiveness, and precision. Among the most popular options are laser cutting and CNC machining, each offering unique advantages that cater to different project needs. This guide will help you navigate through the intricacies of laser vs CNC technologies, ensuring you make an informed decision for your next project.

Understanding Laser Cutting Technology

Laser cutting technology employs focused beams of light to slice through materials with incredible precision. This method is widely used across various industries due to its ability to create intricate designs without physical contact between the cutting machine laser and the material being processed. With advancements in laser machinery, a good laser cutter can achieve remarkable results on a range of materials including metals, plastics, and wood.

Unpacking CNC Machining Basics

CNC (Computer Numerical Control) machining involves using pre-programmed software to control machine tools for precise manufacturing tasks. Unlike laser cutting, which uses light as its primary tool, CNC machines employ various tools such as drills and lathes to shape materials into desired forms. The versatility of a CNC cutting machine makes it suitable for a wide array of applications—from creating complex parts for aerospace to custom furniture pieces.

Why You Should Care About Laser vs CNC

Understanding the differences between laser cutting and CNC machining is crucial for anyone involved in production or design processes. Each technology has distinct strengths that can significantly impact project outcomes—whether it's speed, accuracy, or material compatibility. By weighing these factors carefully against your specific needs, you can select either a good laser cutter or an efficient CNC machine that aligns perfectly with your operational goals.

Overview of Laser Cutting

This method utilizes focused light beams to slice through various materials with remarkable accuracy, making it a popular choice in various industries. As we dive into the world of laser cutting, let's explore what it is, its key applications, and the advantages that make it a go-to option for many businesses.

What is Laser Cutting?

Laser cutting is a process that employs a high-powered laser beam to cut or engrave materials with extreme precision. The laser machine directs energy onto the material's surface, which either melts or vaporizes it away, leaving behind clean edges and intricate designs. This technology has revolutionized how we approach manufacturing and design due to its ability to create complex shapes without the need for extensive tooling.

Key Applications of Laser Technology

The applications of laser technology are vast and varied, spanning multiple industries from automotive to textiles. In manufacturing settings, a good laser cutter can efficiently produce parts for machinery or vehicles with minimal waste and maximum detail. Additionally, sectors like fashion utilize laser cutting for fabric patterns while sign makers rely on this technology for custom signage—showing just how integral it has become in modern production processes.

Advantages of Laser Cutting

One of the standout advantages of using a cutting machine laser is its unparalleled precision; even the most intricate designs can be executed flawlessly without compromising on quality. Furthermore, laser machinery offers flexibility since it can work with an array of materials such as metal, wood, glass, and plastics—often yielding better results than traditional methods like CNC machining in certain scenarios. Lastly, operating costs tend to be lower over time due to reduced material wastage and faster production speeds compared to other techniques; thus making laser cutting an appealing option when considering your project needs.

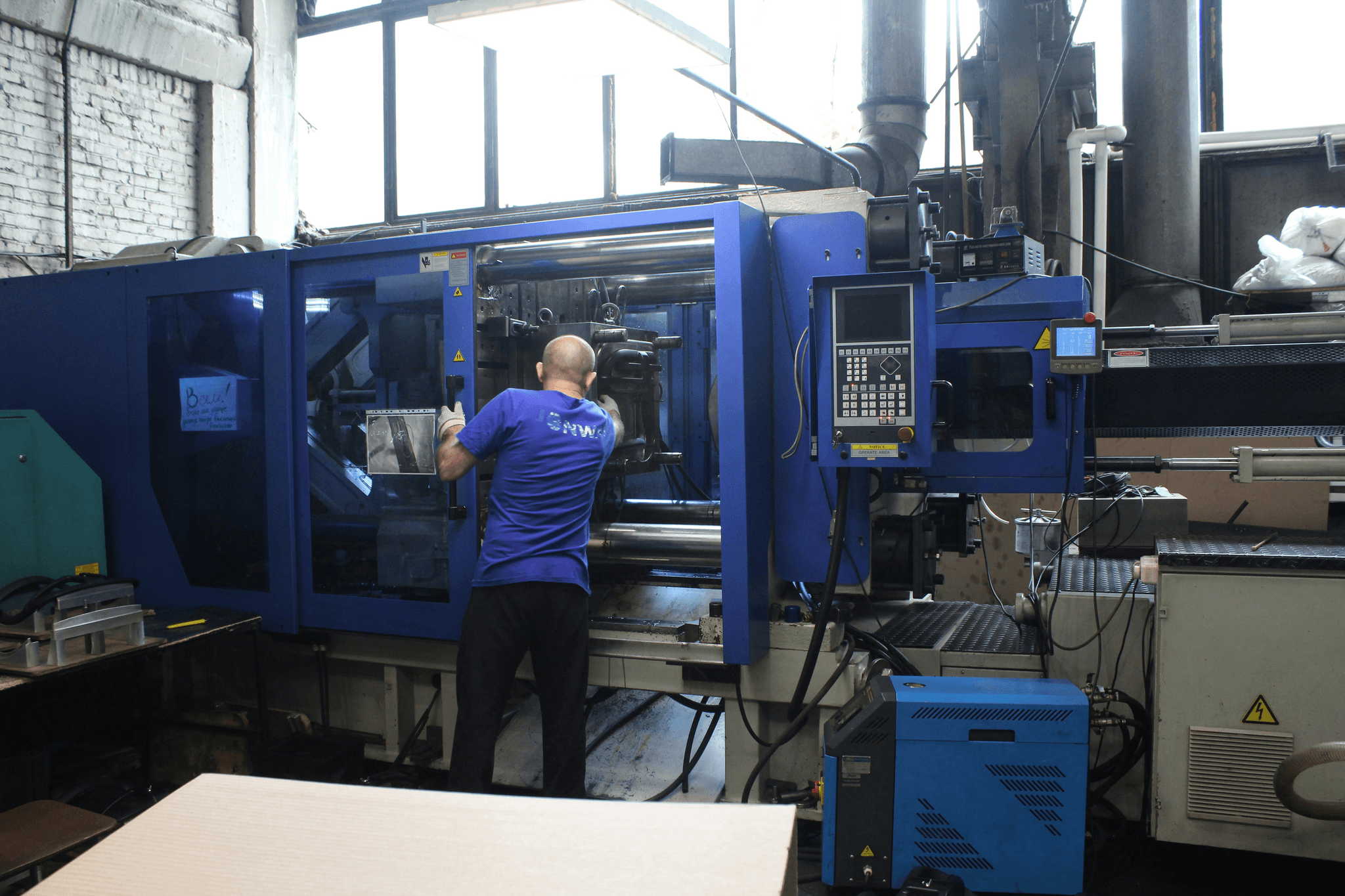

Overview of CNC Machining

CNC machining is a game-changer in the manufacturing world, offering precision and efficiency that traditional methods can’t match. Short for Computer Numerical Control, CNC machining utilizes computer software to control machine tools, ensuring accuracy in cutting and shaping materials. Whether you're crafting intricate components or large-scale parts, a CNC cutting machine can get the job done with remarkable consistency.

What is CNC Machining?

At its core, CNC machining involves automating machine tools via computer programming to perform various tasks like drilling, milling, and turning. This technology allows for complex designs that would be nearly impossible to achieve manually. The result? A high level of precision that keeps production timelines tight and quality standards high – a stark contrast when you consider laser vs CNC options.

Common Uses for CNC Machines

CNC machines are incredibly versatile and find applications across numerous industries such as aerospace, automotive, and even art! From creating engine components to crafting custom furniture pieces, the flexibility of a CNC cutting machine allows manufacturers to meet diverse needs efficiently. While laser cutting excels at thin materials or intricate designs, CNC machining shines when dealing with thicker materials or more substantial parts.

Benefits of CNC Machining

One of the primary benefits of using a good laser cutter is its speed; however, when it comes to durability and material versatility, CNC machining holds its ground firmly. With minimal human intervention required once programmed correctly, these machines reduce labor costs while increasing productivity levels significantly. Furthermore, they offer repeatability – producing identical parts consistently over time – making them an invaluable asset in any production line.

Comparing Precision and Accuracy

When it comes to cutting technology, precision and accuracy are the names of the game. Understanding how laser cutting stacks up against CNC machining is essential for anyone looking to invest in a cutting machine. Both technologies offer unique benefits, but their effectiveness can vary significantly based on the project requirements.

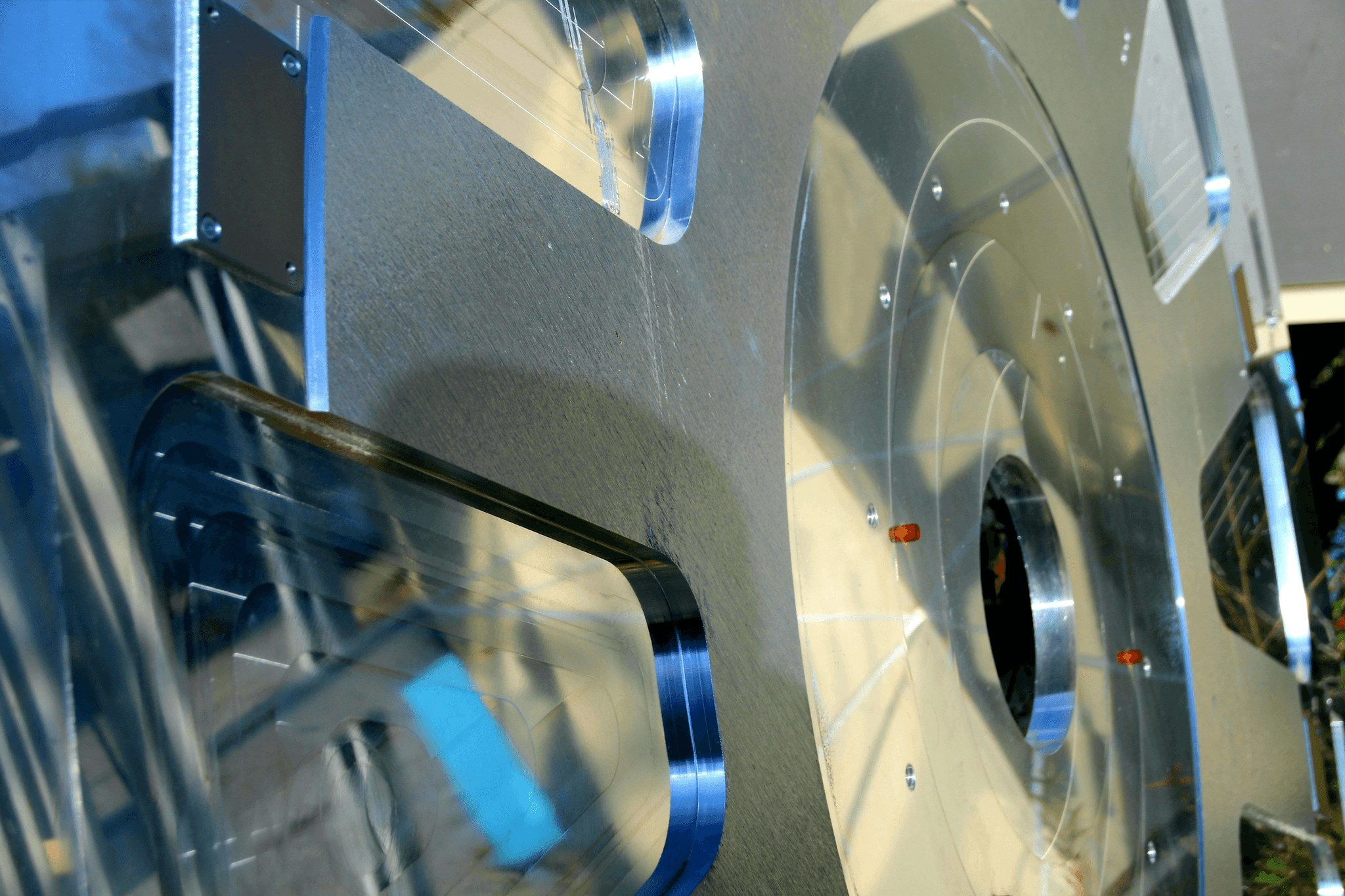

Laser Precision Explained

Laser cutting is renowned for its exceptional precision, making it a go-to choice for intricate designs and detailed work. The focused beam of a good laser cutter allows for incredibly fine cuts, often achieving tolerances as tight as 0.001 inches. This level of precision means that when you’re comparing laser vs CNC, laser machinery often wins out in scenarios where detail is paramount.

Moreover, the minimal heat-affected zone (HAZ) produced by laser machines ensures that materials retain their integrity without warping or distortion during the cutting process. This characteristic is particularly beneficial when working with sensitive materials like plastics or thin metals, where even slight imperfections can lead to significant issues down the line. Therefore, if your project demands high detail and flawless edges, investing in a quality laser cutting system could be your best bet.

CNC Accuracy Features

On the other hand, CNC machining boasts its own set of accuracy features that make it an attractive option for many industries. With mechanical components designed to move with precision along multiple axes, CNC cutting machines can achieve remarkable repeatability—often within ±0.005 inches or better depending on the setup and tooling used. This makes CNC ideal for bulk production runs where consistency across multiple parts is crucial.

Additionally, CNC machines can handle a wide variety of materials—from metals to woods—while maintaining their accuracy throughout long production cycles. Unlike some laser technologies that may struggle with thicker materials or certain composites, CNC machining adapts well without compromising on performance or results. When considering laser vs CNC options for projects requiring both versatility and accuracy over time, it's clear that each has its strengths.

Real-World Examples of Precision

To illustrate these differences more concretely, let’s look at some real-world applications where precision plays a critical role in choosing between a good laser cutter and a CNC machine. In aerospace manufacturing, for instance, intricate components often require meticulous details; here’s where laser machinery shines due to its ability to create complex geometries without sacrificing strength or structural integrity.

Conversely, in automotive production lines where parts need uniformity across thousands of units—such as brackets or housings—a reliable CNC cutting machine would be favored due to its capability to produce identical pieces efficiently over large quantities while maintaining tight tolerances throughout each cycle.

In summary, whether you lean towards a powerful laser machine or an efficient CNC setup will depend largely on your specific needs regarding precision and accuracy in your projects.

Material Compatibility

Best Materials for Laser Cutting

Laser cutting is a champion when it comes to thin and delicate materials like acrylic, wood, and certain metals. The precision of a good laser cutter allows for intricate designs that would be challenging to achieve with other methods. Additionally, laser machines can effortlessly handle non-metal materials, such as plastics and paper, making them incredibly versatile in various industries.

The speed of laser cutting is another advantage when working with materials like fabric or cardboard, where high-speed cuts are essential for efficiency. However, while lasers excel at thin sheets, thicker materials may require multiple passes or may not be feasible at all—something to consider when evaluating your options in the laser vs CNC debate. In summary, if your project involves lightweight or delicate materials requiring fine detail work, a cutting machine laser could be your best bet.

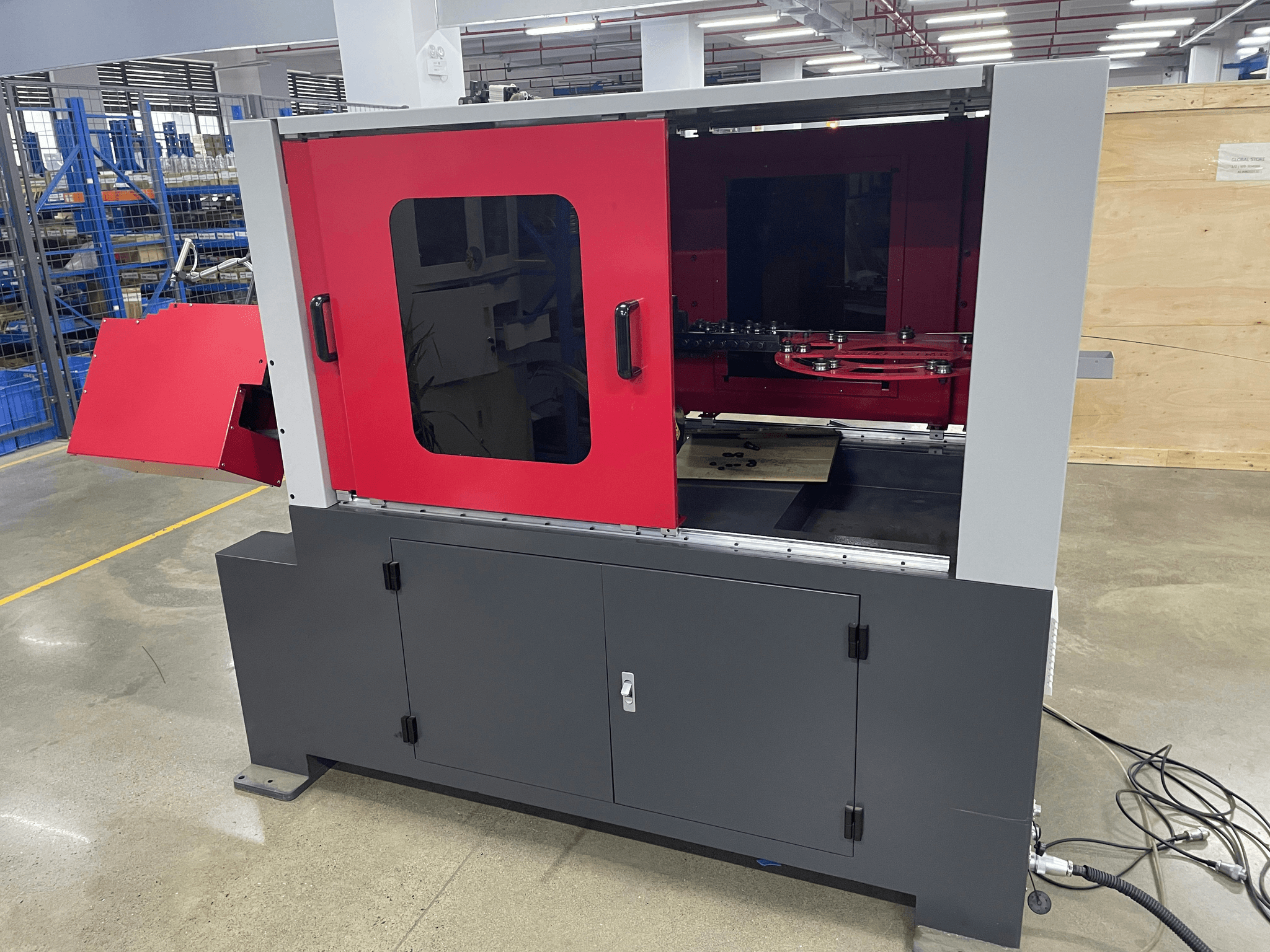

Materials Perfect for CNC Machining

On the flip side of the coin lies CNC machining—a robust process ideal for harder and thicker materials such as metals (aluminum, steel), wood composites, and even some plastics. Unlike its counterpart in the laser vs CNC showdown, CNC machines can handle much greater material thickness without compromising on quality or precision. This makes them particularly suited for heavy-duty applications in industries like aerospace and automotive.

CNC cutting machines shine in producing parts that require tight tolerances or complex geometries that demand multi-axis capabilities—a feat that many good laser cutters struggle with due to their limitations on thickness and material type. Furthermore, while both technologies have their strengths, CNC machining often provides better surface finishes on certain hard metals compared to traditional laser methods. So if you’re working with tough stuff that needs durability over delicacy—CNC is where you want to be.

Limitations of Each Technology

While both technologies have their unique advantages tailored to specific projects, they also come with inherent limitations worth noting in this ongoing discussion about laser vs CNC capabilities. For instance, while a good laser cutter excels at speed and detail on thinner materials like acrylics or fabrics; it struggles significantly with thicker metals where precision might falter due to heat distortion or required multiple passes.

Conversely, CNC machining is not without its drawbacks either; although it's fantastic for heavier workloads and intricate designs on robust materials—it tends to be slower than laser processes when dealing with extensive cut patterns on lighter substrates. Additionally, setup times can be longer due to tooling changes needed based on the material being machined—this adds an extra layer of complexity compared to simply loading up a sheet into a cutting machine laser.

In conclusion—understanding these nuances will help you make an informed choice tailored specifically towards your project's unique requirements regarding material compatibility!

Cost Considerations

Both technologies come with their own financial implications, from initial investments to ongoing operational costs. Understanding these costs will help you determine which cutting technology aligns best with your budget and project needs.

Initial Investment in Laser vs CNC

The initial investment for a good laser cutter can be quite hefty, especially for high-quality laser machinery designed for industrial use. Prices can vary widely based on the power of the laser and its capabilities; however, they typically range from several thousand to tens of thousands of dollars. In contrast, a CNC cutting machine might present a lower entry price point, but depending on the complexity and features required, you could still find yourself facing a steep investment.

It's essential to consider not just the purchase price but also what additional equipment or software might be necessary for each system. For instance, while some laser machines come fully equipped with advanced features out-of-the-box, others may require additional components like cooling systems or exhaust units that add to the overall cost. Ultimately, weighing these factors will give you a clearer picture of the financial commitment involved in either technology.

Operating Costs Explained

Operating costs are another crucial aspect when comparing laser vs CNC technologies. Laser cutting machines generally have lower maintenance costs because they have fewer moving parts compared to their CNC counterparts; this leads to less wear and tear over time. However, you must account for consumables such as lenses and gas used in certain types of lasers which can add up over time.

On the other hand, CNC machining often requires more frequent maintenance due to its mechanical components—think motors and gears that need regular checks and replacements. Additionally, energy consumption is another factor; while both processes consume electricity, high-powered lasers may lead to higher utility bills during operation. Being aware of these ongoing expenses will help you budget more effectively as you consider your options.

Cost-Benefit Analysis

Conducting a cost-benefit analysis is vital when deciding between laser cutting and CNC machining since each method has its unique advantages that could justify their respective costs. For example, if precision is paramount in your projects (and let’s face it—it usually is!), investing in a good laser cutter may yield better long-term results despite its higher upfront cost due to reduced material wastage and faster processing times.

Conversely, if you're working with materials that are better suited for CNC machining—like metals or composites—you might find that investing in a robust cnc cutting machine pays off through durability and versatility over time. Ultimately, it boils down to aligning your project's specific needs with the strengths of each technology while keeping an eye on both immediate expenses and future savings.

Choosing the Right Technology

Both technologies have their unique strengths, so it’s essential to identify the specific requirements of your project before making a decision. Consider factors like material type, design complexity, and production volume to determine which cutting method will yield the best results.

Assessing Project Needs

First and foremost, evaluate the materials you plan to use. If you're working with thin metals or intricate designs, a good laser cutter might be your best bet due to its precision and ability to create clean cuts without significant heat distortion. Conversely, if you need to work with thicker materials or require more robust machining capabilities, a CNC cutting machine could be more suitable for your needs.

Next, think about the complexity of your designs. Laser machinery excels in handling detailed patterns and fine features that might be challenging for traditional CNC machines. Additionally, consider the volume of production; if you're looking at high-volume runs where speed is essential, understanding how each technology can optimize efficiency will guide you toward making an informed choice.

Lastly, don't forget to factor in turnaround times and deadlines. If speed is of the essence in your project timeline, comparing how quickly each method can produce parts will help narrow down your options effectively. Ultimately, assessing these project needs will clarify whether laser vs CNC technology is better suited for your specific application.

Consulting Experts Like Kiant Machinery

Navigating through the world of cutting technologies can be overwhelming without expert guidance. This is where consulting professionals like Kiant Machinery comes into play; they can provide invaluable insights tailored specifically for your situation. Their expertise can help demystify both laser cutting and CNC machining processes so that you feel confident in choosing the right technology.

Moreover, experts can assist in evaluating not just technical specifications but also operational considerations such as maintenance requirements and training needs for staff who will operate these machines regularly. A good laser cutter may require different handling than a CNC cutting machine; thus having knowledgeable support ensures smoother transitions during implementation.

Additionally, consulting industry experts often leads to discovering innovative solutions or techniques that may not be immediately apparent when simply researching online or reading manuals alone. So don’t hesitate—reach out for professional advice when determining whether laser vs CNC suits your projects best!

Factors Influencing Your Decision

Several factors come into play when deciding between laser cutting machinery and CNC machining tools that go beyond just material compatibility or design intricacies. One significant consideration is cost; initial investments vary widely between a good laser cutter versus a full-fledged CNC setup depending on features like automation levels and software capabilities.

Another aspect influencing this decision is scalability—how well each technology adapts as production demands change over time? If you're anticipating growth or fluctuations in order sizes frequently, understanding which machine offers better flexibility could save you time—and money—in the long run.

Finally, consider support services offered by manufacturers post-purchase since ongoing maintenance plays a vital role in ensuring optimal performance from either type of equipment over its lifespan! Whether it's training staff on using new equipment effectively or having access to reliable customer service when issues arise—these elements are critical factors that should influence whether you choose laser vs CNC technology for future projects.

Conclusion

In the battle of laser vs CNC, both technologies have their unique strengths and weaknesses. Understanding these differences is crucial for businesses and hobbyists alike when choosing the right cutting machine for their specific needs. Whether you opt for a good laser cutter or a CNC cutting machine, your decision should align with your project goals.

Key Takeaways on Laser vs CNC

When comparing laser cutting and CNC machining, precision stands out as a significant factor. Laser machinery excels in intricate designs and thin materials, making it ideal for applications like signage and delicate arts. On the other hand, CNC machines offer robust versatility with various materials, including metals and plastics, making them perfect for heavy-duty tasks.

Cost is another critical consideration; while the initial investment in a quality laser machine can be higher, operating costs may balance out over time due to lower maintenance needs. Additionally, understanding material compatibility is vital: some materials are best suited for laser cutting while others thrive under CNC machining conditions. Ultimately, assessing your project requirements will guide you toward the most suitable option.

Future Trends in Cutting Technology

The landscape of cutting technology continues to evolve rapidly, with innovations that promise greater efficiency and capabilities. For instance, advancements in hybrid machines that combine both laser vs CNC functionalities are on the rise, allowing users to enjoy the best of both worlds without compromising on quality or speed. Furthermore, automation and AI integration are set to enhance precision even further while reducing human error in both laser cutting and CNC machining processes.

Sustainability is also becoming a focal point; more manufacturers are developing eco-friendly practices in their operations which could influence future technology choices significantly. As industries increasingly seek ways to minimize waste and energy consumption during production processes, expect to see greener options emerge within both laser machinery and CNC systems. Keeping an eye on these trends will help you stay ahead of the curve.

Final Thoughts on Making the Right Choice

Choosing between a good laser cutter or a CNC cutting machine ultimately boils down to understanding your specific needs—be it precision design work or robust industrial applications. Take time to evaluate factors such as material types you'll work with and budget constraints before making your decision; this will save you from potential headaches later on! Consulting experts like Kiant Machinery can provide invaluable insights tailored specifically to your situation.

In conclusion, whether you lean towards laser vs CNC technologies depends largely on what you're aiming to achieve with your projects today—and tomorrow! The right choice can lead not only to superior results but also open doors for future innovations that keep pace with industry trends.