Introduction

In recent years, laser pipe cutting has emerged as a game-changer in the manufacturing landscape. This innovative technology has transformed how industries approach precision cutting, allowing for cleaner cuts and enhanced efficiency. The rise of laser cutting machines signifies a shift towards more advanced methods of machine cut metal, offering solutions that were previously unimaginable.

The Rise of Laser Pipe Cutting

The adoption of laser pipe cutting technology has skyrocketed, driven by the demand for precision and speed in production processes. Industries are increasingly turning to machine metal cutters that utilize lasers due to their ability to deliver intricate designs with unparalleled accuracy. As businesses strive for competitive edges in the market, the need for efficient and high-quality metal fabrication solutions has never been greater.

Advantages of Ultra High-speed Machines

Ultra high-speed machines have revolutionized laser cutting by significantly increasing production rates while maintaining exceptional quality standards. These advanced systems enable manufacturers to produce components faster than ever before, reducing lead times and enhancing overall productivity. Moreover, with their precise cutting capabilities, these machines minimize material waste, making them an environmentally friendly choice in today's eco-conscious landscape.

Overview of Key Technologies

At the heart of effective laser pipe cutting lies a blend of sophisticated technologies that work harmoniously together. From fiber lasers to CO2 lasers, each type brings unique advantages tailored to different applications and materials used in machine cut metal processes. Understanding these key technologies is essential for selecting the right laser cutting machine that meets specific industry needs and enhances operational efficiency.

Understanding Laser Pipe Cutting

Laser pipe cutting is a sophisticated process that leverages the power of focused laser beams to slice through various types of materials with incredible precision. This technology has revolutionized how industries approach machining, making it easier to achieve intricate designs and complex shapes in metals. By utilizing advanced optics and computer-controlled systems, laser cutting machines can deliver consistent results that traditional methods struggle to match.

How Laser Cutting Works

At its core, laser cutting involves directing a high-energy beam of light onto the surface of the material being cut. The intense heat generated by the laser melts or vaporizes the material, allowing for clean and precise cuts without significant mechanical force. This method is especially beneficial for machine cut metal applications where accuracy and finish quality are paramount, as it minimizes thermal distortion and maintains tight tolerances.

Types of Laser Cutting Machines

When diving into the world of laser pipe cutting, you'll encounter several types of machines tailored for specific applications and materials. CO2 lasers are popular for non-metallic materials but can also handle thin sheets of metal effectively; however, fiber lasers have taken center stage in recent years due to their efficiency with reflective metals like copper or brass. Each type brings unique benefits depending on your needs—whether you're looking for speed or versatility.

Another option includes solid-state lasers which provide high power output suitable for thick metal sections often found in heavy-duty industries such as construction or aerospace manufacturing. For those needing flexibility, portable laser cutting machines offer convenience without sacrificing performance; they allow operators to move around job sites easily while still delivering precision cuts on demand. Ultimately, selecting the right machine metal cutter depends on your specific operational requirements.

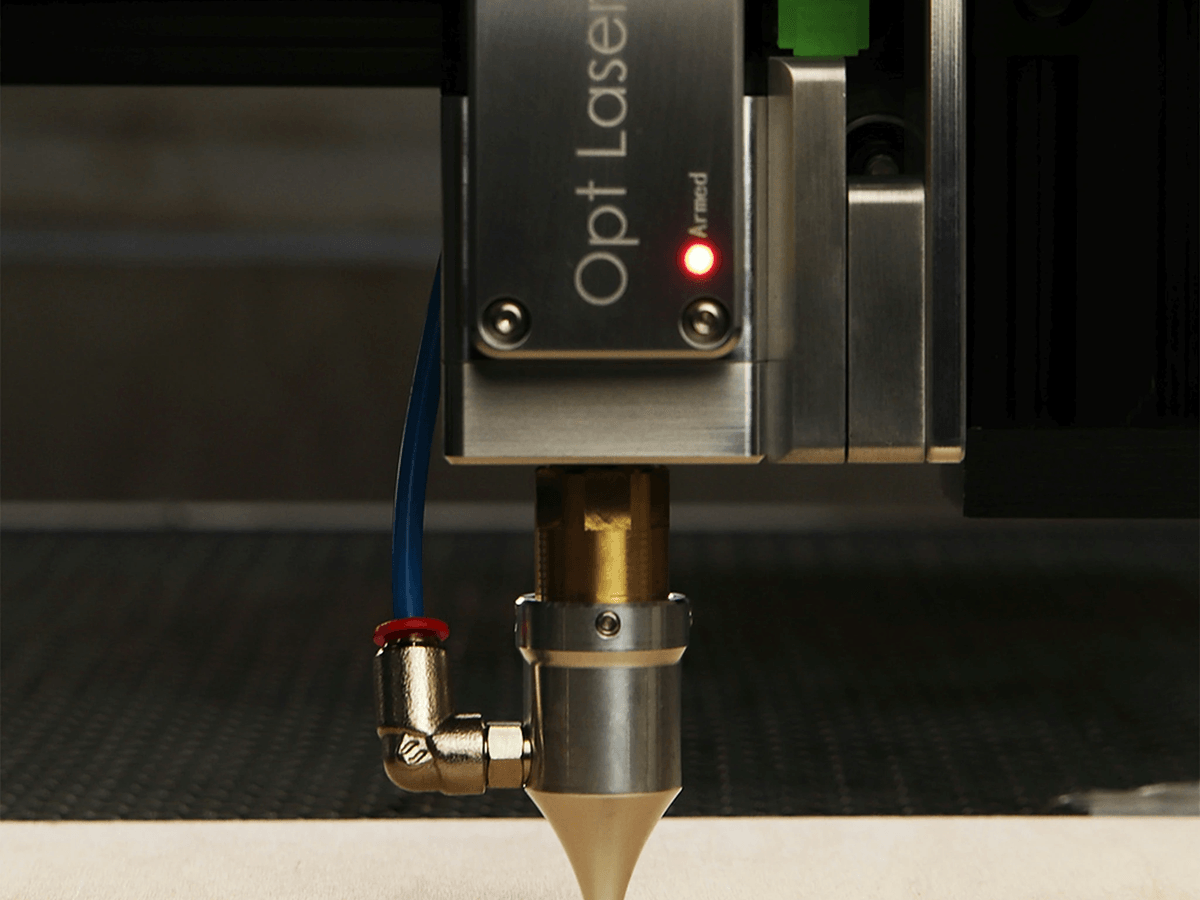

Key Components of a Laser Cutting System

A complete laser cutting system comprises several key components that work harmoniously to achieve superior results in laser pipe cutting applications. At its heart lies the laser source—either CO2 or fiber—that generates the beam necessary for cutting through various materials efficiently. Coupled with this is an optics system that focuses the beam onto the workpiece; this component is crucial as it determines both cut quality and speed.

Control systems play a vital role too—they guide the movement of both the workpiece and the laser head based on pre-programmed designs or real-time adjustments during operation. Additionally, proper cooling systems are essential since excessive heat can damage components or affect performance over time; therefore, effective cooling mechanisms ensure longevity and reliability in machine metal cutter operations. With these components working together seamlessly, users can maximize productivity while achieving outstanding precision in every cut made by their advanced machinery.

The Benefits of Ultra High-speed Technology

In the world of manufacturing, speed is often equated with success, and ultra high-speed technology in laser pipe cutting is no exception. Thanks to advancements in laser cutting machines, manufacturers can now achieve impressive production rates that were once thought impossible. This increased efficiency not only boosts output but also enhances competitiveness in a fast-paced market.

Faster Production Rates

One of the most significant benefits of ultra high-speed technology is its ability to dramatically increase production rates. With laser pipe cutting machines operating at blistering speeds, businesses can machine cut metal components faster than traditional methods allow. This means more products can be produced in a shorter timeframe, ultimately leading to higher profits and quicker turnaround times for clients.

Moreover, the rapid pace of these machines reduces bottlenecks in the manufacturing process. When using a machine metal cutter designed for ultra high-speed operation, industries can respond swiftly to fluctuating demands without compromising quality or precision. As a result, organizations are better equipped to meet customer expectations while maintaining their competitive edge.

Precision and Quality in Cutting

Ultra high-speed laser cutting isn't just about speed; it’s also about achieving exceptional precision and quality in every cut made by the machine metal cutter. These advanced systems utilize finely-tuned optics and sophisticated control software that deliver consistent results across various materials and thicknesses. The accuracy achieved through laser pipe cutting minimizes the need for secondary processes, ensuring that each piece meets stringent quality standards right off the bat.

Additionally, this level of precision translates into fewer errors during production runs. When you invest in a top-of-the-line laser cutting machine, you’re not only improving speed but also enhancing your ability to produce intricate designs with remarkable detail—something traditional methods often struggle with. As such, companies leveraging ultra high-speed technology find themselves at an advantage when it comes to product innovation and differentiation.

Reduced Material Waste

Another compelling advantage of using ultra high-speed laser cutting technology is its capacity to significantly reduce material waste during production processes. Unlike conventional machining techniques that may require extensive trimming or adjustments after initial cuts, laser pipe cutting allows for highly efficient designs with minimal excess material left behind. This efficiency not only conserves resources but also translates into cost savings over time.

Furthermore, precise cuts mean that manufacturers can maximize their use of raw materials without compromising on quality or performance—an essential factor in today’s environmentally-conscious marketplace where sustainability matters more than ever before. By choosing a reliable machine metal cutter equipped with advanced features tailored for efficiency and accuracy, businesses position themselves as leaders committed to responsible manufacturing practices while still meeting market demands.

In conclusion, adopting ultra high-speed technology in laser pipe cutting brings forth an array of benefits including faster production rates, unparalleled precision and quality in every cut made by the machine metal cutter, as well as reduced material waste—a trifecta that propels businesses toward greater success.

Applications Across Industries

Laser pipe cutting technology has revolutionized various sectors, showcasing its versatility and efficiency. From automotive innovations to aerospace advancements, the impact of laser cutting is profound. Additionally, construction and fabrication industries have embraced this technology for its precision and speed in machine cut metal applications.

Automotive Industry Innovations

In the automotive industry, laser pipe cutting has become a game changer for manufacturers looking to streamline their production processes. With the ability to machine cut metal components with high precision, automotive companies can produce intricate designs that were once deemed impossible with traditional methods. This not only enhances vehicle performance but also reduces weight, leading to improved fuel efficiency.

Moreover, laser cutting machines are increasingly used for creating complex geometries in exhaust systems and chassis components. The speed of ultra high-speed machines allows for faster turnaround times on production lines, giving manufacturers a competitive edge. As the demand for electric vehicles rises, the need for lightweight materials processed by advanced metal machine cutters will only continue to grow.

Aerospace and Defense Uses

The aerospace and defense industries rely heavily on laser pipe cutting due to its unmatched precision and reliability. In these sectors, even the smallest error can lead to catastrophic failures; thus, using a machine metal cutter that delivers consistent quality is critical. Laser cutting technology enables manufacturers to create parts that meet stringent safety standards while minimizing material waste.

Additionally, aerospace applications benefit from the ability of laser cutting machines to work with various materials such as titanium and aluminum alloys. These materials are essential for constructing lightweight yet durable components required in aircraft design and military equipment. As these industries evolve towards more complex designs and sustainable practices, laser pipe cutting will play an integral role in shaping their future.

Construction and Fabrication Solutions

In construction and fabrication solutions, laser pipe cutting has proven invaluable for fabricators seeking efficiency without sacrificing quality. The ability of a metal machine cutter to produce clean cuts on pipes means less time spent on finishing processes like grinding or polishing—saving both time and resources on job sites. This translates into quicker project completions while maintaining high standards of craftsmanship.

Moreover, many construction projects require customized piping solutions tailored specifically to site conditions or design specifications; laser cutting machines excel at producing these one-off designs swiftly without compromising accuracy or integrity. Whether it's structural steelwork or intricate architectural features, employing advanced laser technology ensures that builders can meet client expectations effectively while maximizing ROI through efficient resource use.

Choosing the Right Laser Cutting Machine

Selecting the right laser cutting machine can feel like navigating a maze, especially when you're confronted with a variety of options and features. Whether you're looking to enhance your laser pipe cutting capabilities or streamline your metal fabrication processes, understanding what to prioritize is crucial. With the right machine metal cutter, you can optimize your production efficiency and quality.

Factors to Consider When Selecting

When it comes to choosing a laser cutting machine, several factors come into play that can significantly impact your decision. First and foremost, consider the type of materials you’ll be working with; different machines have varying capabilities for cutting metals like steel, aluminum, or even titanium. Next, think about the thickness of the materials—some machines excel in precision for thin sheets while others are designed for heavy-duty applications.

Another critical factor is the power output of the laser; higher wattage typically translates into faster cutting speeds and greater efficiency in machine cut metal projects. Additionally, assess your production volume needs; if rapid turnaround times are essential for your business, investing in ultra high-speed machines might be worth considering. Finally, don’t overlook support and maintenance services offered by manufacturers; reliable customer service can save you time and money in the long run.

Comparing Brands: Kiant Machinery vs Competitors

When comparing brands for laser pipe cutting solutions, Kiant Machinery stands out due to its innovative technology and robust performance metrics. Many competitors offer similar features but may lack the same level of support or customization options that Kiant provides. For instance, while some brands focus on budget-friendly models with basic features, Kiant Machinery ensures that their machines deliver precision without compromising on speed or quality.

In terms of user experience, customers often report that Kiant's interface is more intuitive compared to other machine metal cutter brands on the market. This ease of use allows operators to maximize productivity without extensive training sessions—a significant advantage in fast-paced environments like automotive manufacturing or aerospace fabrication. Ultimately, conducting thorough research on customer reviews and product specifications will help you make an informed choice between Kiant Machinery and its competitors.

Machine Metal Cutter Features to Look For

When shopping for a laser cutting machine, there are specific features you should keep an eye out for that will enhance your overall experience with laser pipe cutting tasks. One essential feature is adjustable power settings which allow operators to customize cuts based on material types and thicknesses—this flexibility is invaluable when dealing with diverse projects. Additionally, look for machines equipped with advanced cooling systems; they help maintain optimal performance during extended operation periods.

Another important aspect is automation capabilities; automated loading systems can significantly reduce downtime between cuts while ensuring consistent accuracy across batches of parts being produced through machine cut metal techniques. Furthermore, consider investing in a model that offers advanced software integration—this allows seamless communication between design files and machine operations while providing real-time monitoring capabilities as well.

In summary, selecting the right laser cutting machine requires careful consideration of various factors such as material compatibility, brand reputation (like Kiant Machinery), and specific features tailored towards enhancing productivity in your operations.

Maintenance and Troubleshooting Tips

Maintaining a laser cutting machine is crucial for ensuring optimal performance and longevity. Regular maintenance practices not only prevent unexpected breakdowns but also enhance the precision of your laser pipe cutting operations. By committing to a routine, you can keep your metal machine cutter running smoothly and efficiently.

Regular Maintenance Practices

To keep your laser cutting machine in top shape, establish a regular maintenance schedule that includes cleaning, inspection, and calibration. Start by regularly checking the optics; dust and debris can significantly affect the quality of your cuts. Additionally, ensure that all moving parts are lubricated to reduce friction and wear, which is essential for maintaining high-speed operations in laser pipe cutting.

Moreover, it’s vital to monitor the cooling system of your machine metal cutter since overheating can lead to costly damages. Replace worn-out components promptly to avoid any disruptions in production rates. Lastly, always refer to the manufacturer’s guidelines for specific maintenance tips tailored to your particular model of laser cutting machine.

Common Issues and Solutions

Even with diligent maintenance, issues may arise with a laser cutting machine from time to time. One common problem is inconsistent cut quality; this can often be traced back to misaligned optics or worn lenses affecting the beam focus. Adjusting or replacing these components usually resolves such issues quickly.

Another frequent issue is material warping during the cutting process, which can occur when settings like speed or power are not properly calibrated for specific materials being used in metal machine cutters. Ensuring that parameters are correctly set based on material thickness will help mitigate this problem effectively. If you encounter persistent errors or malfunctions beyond basic troubleshooting, it may be time to consult an expert.

When to Call the Experts

While many minor issues can be resolved through regular maintenance practices and troubleshooting techniques, some situations warrant professional assistance. If you notice recurrent problems despite following best practices for care—such as frequent misalignment or erratic performance—it’s wise to call in experts who specialize in laser pipe cutting machinery.

Additionally, if there's a significant drop in production efficiency or unusual noises coming from your metal machine cutter that you cannot identify, don’t hesitate to seek help from professionals who understand the intricacies of these systems. Investing in expert services not only ensures safety but also prolongs the lifespan of your equipment while maximizing ROI on your investment in advanced technology like laser cutting machines.

Conclusion

In the ever-evolving landscape of manufacturing, laser pipe cutting technology stands at the forefront of innovation. As industries strive for greater efficiency and precision, the demand for advanced laser cutting machines is set to rise exponentially. The future looks bright for those who embrace these technologies, making it essential to stay informed about advancements in machine metal cutter capabilities.

The Future of Laser Cutting Technology

The future of laser cutting technology promises even faster speeds and enhanced precision, making it an indispensable tool for manufacturers. With ongoing research and development, we can expect to see improved laser sources and automation features that will further streamline the cutting process. This evolution will not only enhance productivity but also open doors to new applications in various sectors, from automotive to aerospace.

Investing in Efficiency with Kiant Machinery

Investing in a high-quality laser cutting machine from Kiant Machinery means committing to efficiency and reliability. Their advanced machine metal cutter solutions are designed with user-friendly interfaces and robust performance features that help businesses maximize their output while minimizing downtime. By choosing Kiant Machinery, companies can ensure they have a competitive edge in the market through superior laser pipe cutting capabilities.

Maximizing ROI with Laser Pipe Cutting Solutions

Maximizing return on investment (ROI) with laser pipe cutting solutions involves understanding both the initial costs and long-term benefits of these systems. Efficient operation leads to reduced material waste and faster production rates, translating into significant savings over time. By selecting the right machine cut metal technology tailored to specific needs, businesses can achieve remarkable financial gains while maintaining high standards of quality.