Introduction

In the world of manufacturing and fabrication, the quest for efficiency and precision has led to the rise of Easy Tube Cutting Machines. These innovative machines are designed to streamline the process of cutting metal tubes, making it easier than ever to achieve clean, precise cuts without the hassle of traditional methods. With advancements in technology, particularly in laser cutting, machine cut metal has reached new heights, offering unparalleled speed and accuracy.

Discovering Easy Tube Cutting Machines

Easy Tube Cutting Machines have revolutionized how industries handle tube cutting tasks. By utilizing advanced technologies such as laser cutting machines and fiber lasers, these machines provide users with a reliable solution for their tube processing needs. Whether it's for automotive applications or structural components, an easy tube cutting machine ensures that every cut is executed with precision.

The Benefits of Chipless Tube Cutting

One standout feature of modern tube cutting technology is chipless tube cutting, which minimizes waste while maximizing efficiency. This technique not only reduces material loss but also enhances the overall quality of machine cut metal products by eliminating burrs and sharp edges typically associated with traditional methods. As a result, businesses can enjoy significant cost savings while maintaining high standards in production.

Overview of Laser Cutting Technologies

Laser cutting technology has transformed the landscape of manufacturing by providing exceptional capabilities in various applications. From intricate designs to heavy-duty industrial tasks, a cutting machine laser can handle it all with remarkable precision and speed. Fiber laser systems have emerged as a leading choice among manufacturers due to their energy efficiency and versatility in working with different materials—including metals—making them an essential tool for any modern workshop.

Understanding Easy Tube Cutting Machines

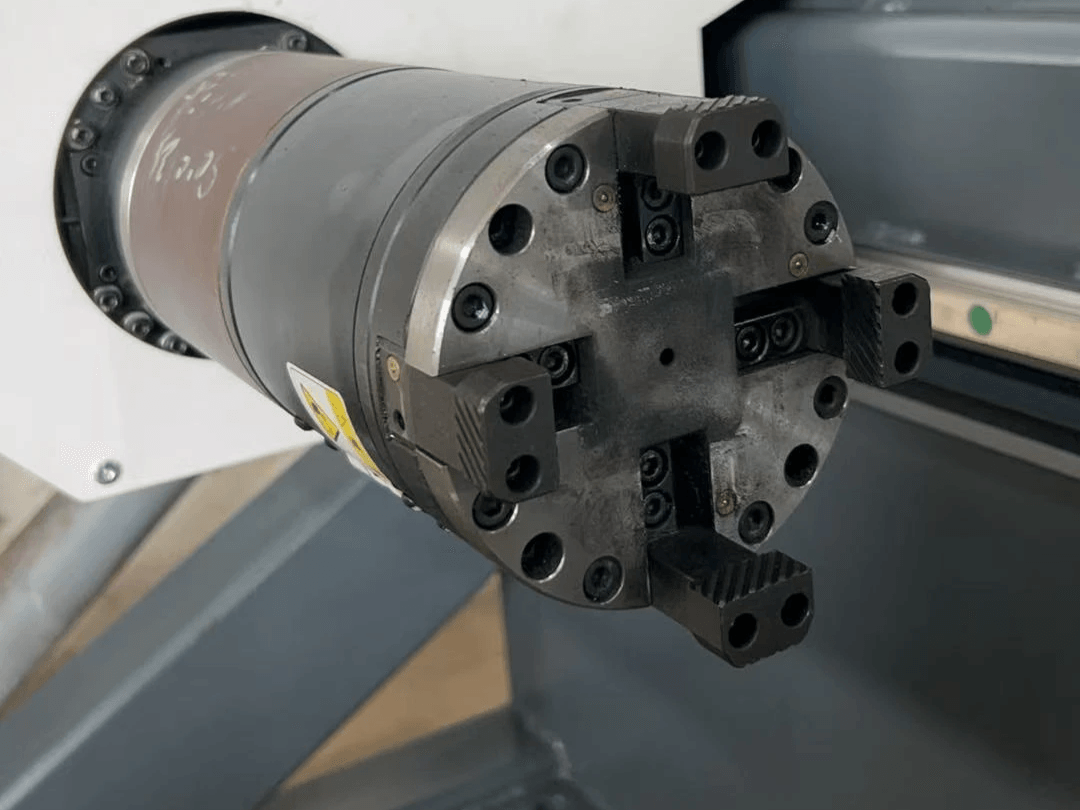

Definition and Functionality

An Easy Tube Cutting Machine is a specialized device engineered to cut metal tubes with high precision and efficiency. Unlike traditional methods that may produce chips or debris, these machines often employ chipless techniques like laser cutting, which minimizes waste while ensuring a smooth finish. The functionality of these machines varies from simple manual operations to fully automated systems, catering to different production needs.

Different Types of Tube Cutting Machines

There are several types of tube cutting machines available on the market today, each designed for specific applications and materials. Laser cutting machines have gained immense popularity due to their ability to handle various metals with ease, while fiber lasers offer enhanced speed and precision for more demanding tasks. Other types include saw-based cutters and plasma cutters, which serve niche markets but may not provide the same level of finesse as a machine metal cutter using laser technology.

Application Areas for Tube Cutting

The application areas for tube cutting are vast and varied, making these machines essential in many sectors. Industries such as automotive manufacturing utilize Easy Tube Cutting Machines for producing exhaust systems or chassis components with precise measurements. Additionally, fields like aerospace engineering benefit from the accuracy of laser cutting when fabricating lightweight yet strong components that meet stringent safety standards.

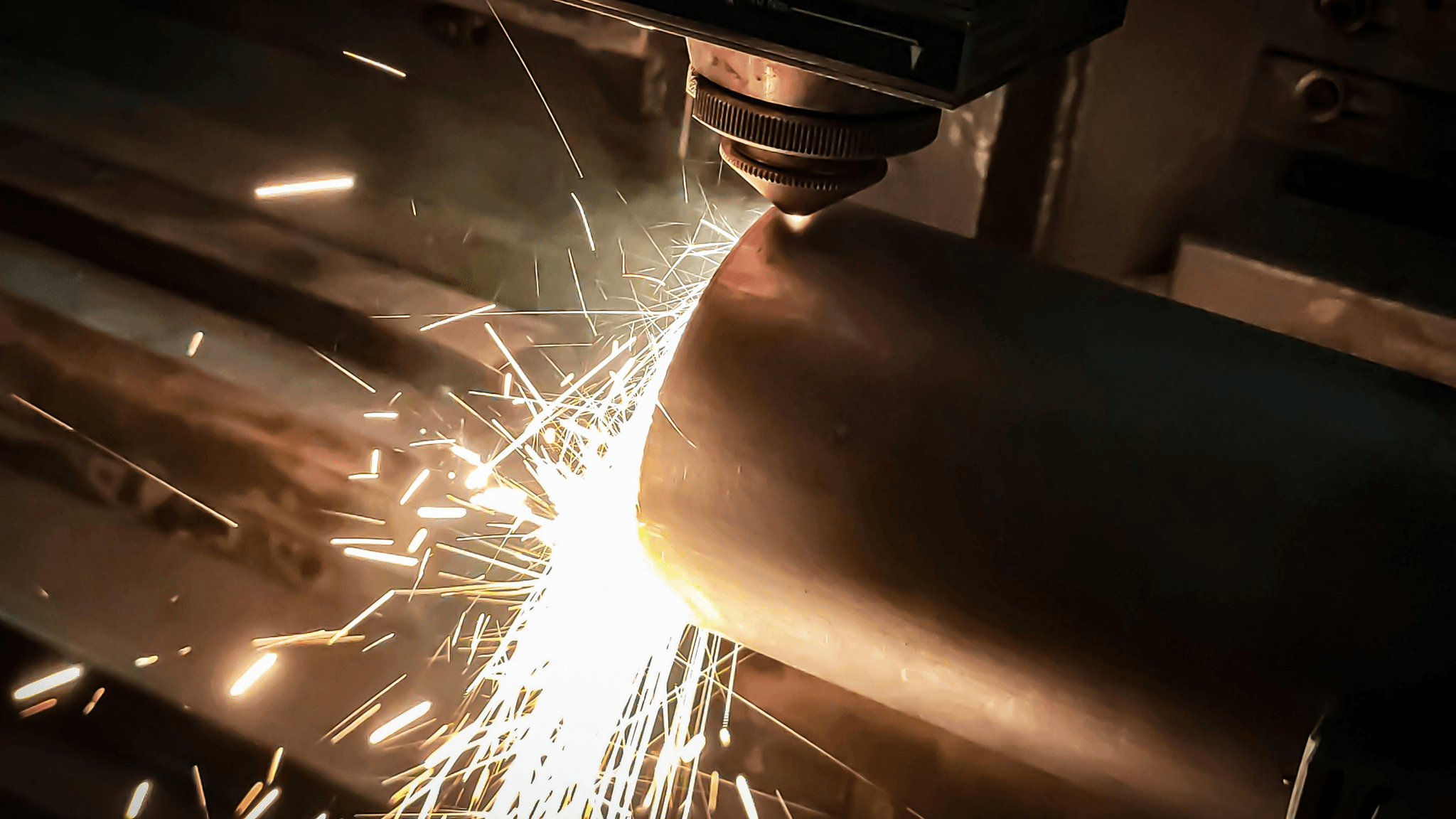

The Mechanics Behind Laser Cutting

Laser cutting has revolutionized the way we approach metal fabrication, particularly in the realm of tube cutting. This technology utilizes focused laser beams to cut through various materials with precision and speed, making it a preferred choice for many industries. Understanding how laser cutting works is essential for anyone looking to invest in an easy tube cutting machine or a machine metal cutter.

How Laser Cutting Works

At its core, laser cutting involves directing a high-powered laser beam onto the material being cut—in this case, tubes made of metal. The intense heat generated by the laser melts or vaporizes the material along a predetermined path, allowing for intricate designs and clean edges without the need for extensive post-processing. This method can be applied across various thicknesses and materials, making it incredibly versatile compared to traditional methods used in machine cut metal operations.

Moreover, modern laser cutting machines often incorporate advanced software that allows users to input precise dimensions and shapes easily. As such, operators can achieve exceptional accuracy with minimal waste—an appealing feature for manufacturers aiming to optimize their production processes. With fiber lasers becoming increasingly popular in tube cutting machines, they offer improved efficiency and energy consumption while maintaining high-quality cuts.

Advantages of Using Laser Cutting Machines

One of the standout advantages of using a laser cutting machine is its unparalleled precision; even complex geometries can be achieved effortlessly. Unlike conventional methods that may produce burrs or require additional finishing work, a well-calibrated cutting machine laser provides smooth edges straight from the cutter—saving both time and resources in post-production processes. Additionally, these machines are generally faster than traditional saws or plasma cutters, which translates into higher throughput rates.

Another significant benefit is versatility; whether you're working with stainless steel tubes or aluminum components, fiber lasers can handle various materials efficiently without compromising on quality. This adaptability makes them ideal for industries ranging from automotive to aerospace where different metals are frequently employed in manufacturing processes. Furthermore, with advancements in technology leading to more compact designs, today's easy tube cutting machines can fit seamlessly into existing workflows without requiring extensive modifications.

Lastly—and perhaps most importantly—laser cutters tend to have lower operational costs over time due to reduced wear on tools and less scrap material produced during cuts compared to traditional methods like sawing or shearing machinery used in machine metal cutter applications. When considering long-term investments for your fabrication shop or production line setup, investing in reliable laser technology could yield substantial savings down the road.

Comparisons with Traditional Cutting Methods

When comparing laser cutting machines with traditional methods such as band saws or oxy-fuel torches, several key differences emerge that highlight why many manufacturers are pivoting toward modern solutions like fiber lasers for their tube-cutting needs. Traditional approaches often involve slower speeds due to mechanical limitations and can result in more rough cuts that necessitate further processing—adding time and labor costs into the equation when working on projects involving machine cut metal tasks.

In contrast, a well-tuned easy tube cutting machine operates at remarkable speeds while delivering consistent accuracy across multiple runs—a feat that manual techniques simply can't match consistently over time! Moreover, traditional methods may struggle with thicker materials where heat buildup becomes problematic; however, advanced fiber lasers maintain optimal performance regardless of thickness thanks to their ability to focus energy precisely where it's needed most.

Ultimately choosing between these two approaches boils down not just to cost but also efficiency levels desired within your operations as you seek out reliable solutions tailored specifically towards enhancing productivity levels through innovative technologies like those found within today’s state-of-the-art cutting machines!

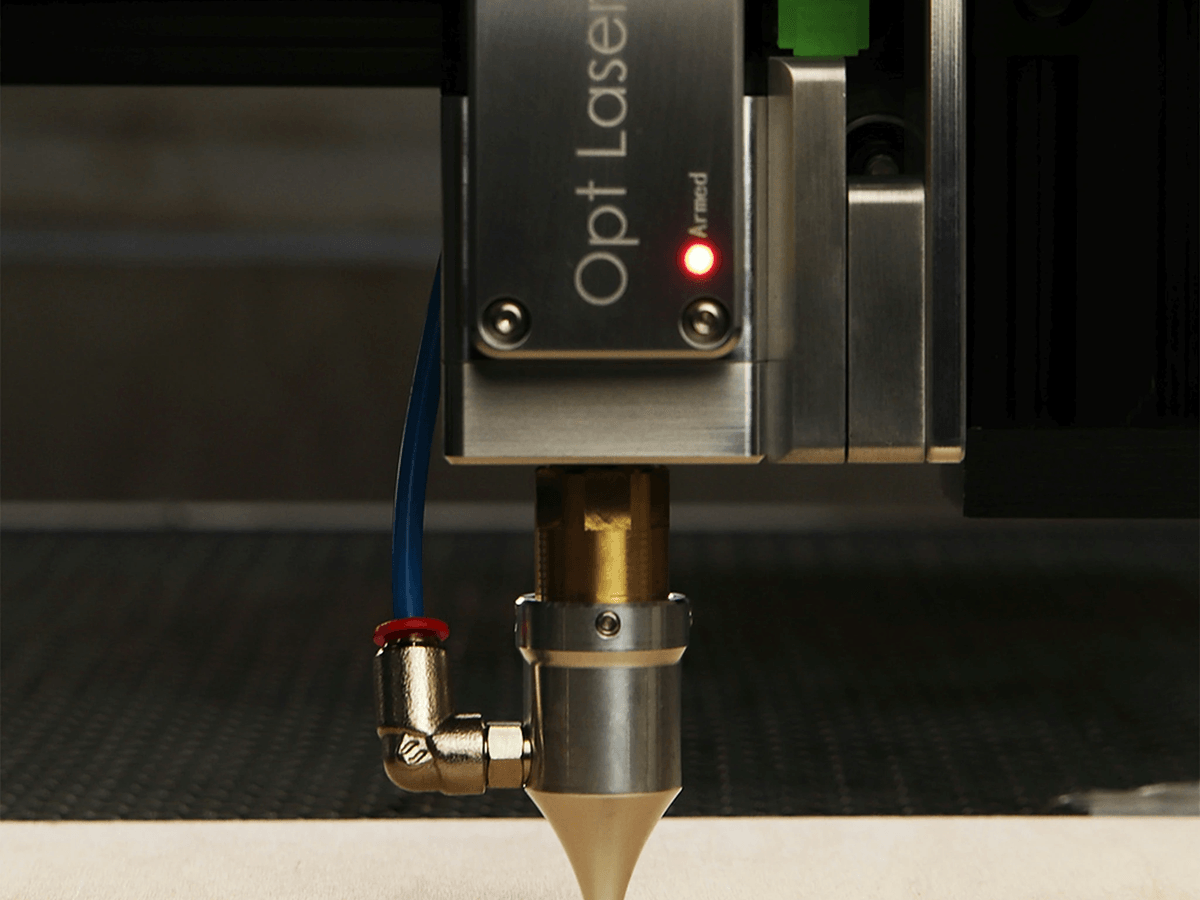

Exploring Fiber Laser Technology

Fiber laser technology has revolutionized the way we approach metal cutting, particularly in the realm of tube cutting machines. Unlike traditional lasers that use mirrors and lenses, fiber lasers utilize a flexible fiber optic cable to generate and amplify the laser beam. This innovative method not only enhances precision but also improves efficiency, making it a go-to solution for industries requiring high-quality machine cut metal.

What is Fiber Laser?

Fiber laser is a type of solid-state laser that employs optical fibers doped with rare-earth elements like ytterbium to produce a coherent light beam. This technology allows for greater energy efficiency and higher output power compared to conventional lasers. In the context of an easy tube cutting machine, fiber lasers excel by delivering consistent performance with minimal maintenance, ensuring long-term reliability in metal processing applications.

Benefits of Fiber Laser in Tube Cutting

First and foremost, they provide exceptional speed and accuracy, allowing for intricate designs and tight tolerances without compromising quality—perfect for any machine metal cutter looking to enhance production capabilities. Additionally, fiber lasers generate less heat during operation, which reduces the risk of warping or damaging delicate materials during the cutting process.

Moreover, these cutting machines are versatile; they can handle various materials such as stainless steel, aluminum, and even copper with ease. The reduced operational costs associated with fiber laser technology make it an attractive investment for businesses looking to optimize their manufacturing processes while maintaining high standards in quality control.

Leading Brands in Fiber Laser Technology

In the competitive landscape of fiber laser technology, several brands stand out for their innovation and reliability in producing top-notch cutting machines. Kiant Machinery has made a name for itself by offering advanced easy tube cutting machines equipped with state-of-the-art laser cutting capabilities that cater specifically to diverse industrial needs. Other notable brands include Trumpf and Mitsubishi Electric; both have established themselves as leaders by providing robust solutions that emphasize precision and durability.

These manufacturers continue to push the boundaries of what’s possible with machine cut metal applications through ongoing research and development efforts aimed at refining their products further. As industries evolve toward more automated processes, investing in leading-edge technologies like those offered by these brands becomes essential for staying competitive in today’s market.

Choosing the Right Machine Metal Cutter

Selecting the right machine metal cutter can feel like navigating a maze, especially with so many options available. The right Easy Tube Cutting Machine can significantly enhance productivity and precision in your operations. By understanding key features and comparing brands, you’ll be better equipped to make an informed decision that aligns with your needs.

Key Features to Look For

When searching for an easy tube cutting machine, several key features should stand out to you. First and foremost is the cutting speed; a faster laser cutting machine often translates to higher efficiency in production. Additionally, consider the machine's versatility—can it handle different materials and thicknesses? Lastly, look for advanced software integration that allows for seamless operation and precise control over the cutting process.

Comparing Brands: Kiant Machinery vs Competitors

Kiant Machinery has established itself as a frontrunner in the world of tube cutting machines, particularly when it comes to their innovative laser cutting technologies. Their machines are designed with user-friendly interfaces and robust construction, making them a popular choice among professionals looking for reliability. However, it's essential to compare their offerings with competitors who may also provide compelling features at competitive prices.

When evaluating other brands against Kiant Machinery, pay attention to customer reviews and case studies showcasing real-world applications of their products. Some competitors might offer lower upfront costs but lack in long-term durability or support services that Kiant provides consistently. Ultimately, understanding how each brand measures up will help you find a machine metal cutter that meets both your operational needs and budget constraints.

Cost vs Quality: Making Informed Decisions

Deciding between cost and quality can be one of the trickiest parts of purchasing an easy tube cutting machine—especially when investing in advanced technology like laser cutters or fiber lasers. While it may be tempting to go for cheaper options initially, remember that quality often pays off through lower maintenance costs and increased efficiency over time. A high-quality laser cutting machine may have a higher price tag but can yield significant savings by reducing waste during production.

It’s also worth considering warranty options offered by various manufacturers; investing slightly more upfront for extended warranties could save you from costly repairs later on if issues arise with your chosen machine metal cutter. Be sure to analyze total cost ownership rather than just sticker price—this includes factors such as energy consumption, replacement parts availability, and potential downtime expenses due to equipment failure or inefficiency.

In conclusion, choosing the right easy tube cutting machine involves balancing key features against brand comparisons while keeping an eye on cost versus quality dynamics—a challenge worth tackling for enhanced productivity!

Real-World Applications of Tube Cutting

From automotive manufacturing to aerospace engineering, the versatility of an Easy Tube Cutting Machine is evident. Laser cutting technology has revolutionized how industries approach precision and efficiency in metal fabrication, making it a game-changer for machine metal cutters everywhere.

Industries That Benefit from Tube Cutting

Numerous industries rely heavily on tube cutting machines, particularly those that require high precision and speed in their operations. The automotive industry, for instance, uses laser cutting machines to create exhaust systems and chassis components with remarkable accuracy. Similarly, the aerospace sector benefits significantly from machine cut metal components that require lightweight yet durable materials; here, fiber laser technology shines by delivering clean cuts without compromising structural integrity.

In addition to automotive and aerospace, the construction industry also employs easy tube cutting solutions for fabricating structural steel and piping systems. Manufacturers dealing with HVAC systems find laser cutting machines indispensable for producing ductwork with exact dimensions and smooth edges. Moreover, medical device manufacturers utilize tube cutting technology for creating specialized instruments where precision is paramount—demonstrating that nearly every sector has something to gain from efficient tube cutting processes.

Case Studies Featuring Kiant Machinery

Kiant Machinery has made significant strides in showcasing how their easy tube cutting machines can transform manufacturing processes across various sectors. For example, a leading automotive supplier implemented a Kiant fiber laser machine cutter to streamline their production line; they reported a 30% reduction in waste material and improved turnaround times on custom orders. This case illustrates not only cost savings but also highlights how effective an advanced laser cutting machine can be in enhancing overall productivity.

Another compelling case study involves a medical equipment manufacturer who adopted Kiant’s advanced tube cutting technology to produce intricate surgical instruments with tight tolerances. By switching to a machine cut metal solution using fiber lasers, they achieved higher precision while reducing labor costs due to fewer manual adjustments needed during production runs. Such examples clearly demonstrate how investing in quality machinery like Kiant’s can yield substantial returns on investment through enhanced efficiency and reduced operational costs.

Enhancing Efficiency with Easy Tube Cutting Machines

The advent of easy tube cutting machines has paved the way for unprecedented efficiency gains in various manufacturing sectors. With features like automated loading systems and real-time monitoring capabilities integrated into modern laser-cutting machines, businesses can achieve higher throughput without sacrificing quality or precision. The ability of these machines to handle diverse materials—from stainless steel to aluminum—further enhances their utility across different applications.

Moreover, adopting advanced technologies such as fiber lasers allows companies not just to cut tubes faster but also more accurately than traditional methods could ever hope for. This shift towards automation helps reduce human error while increasing safety standards within manufacturing environments—a win-win situation! As more industries recognize the advantages of using sophisticated machinery like the Easy Tube Cutting Machine or other innovative solutions from leading brands like Kiant Machinery, we can expect ongoing improvements in efficiency across the board.

Conclusion

In summary, the world of tube cutting has evolved significantly with the introduction of advanced technologies, particularly easy tube cutting machines and laser cutting methods. For those looking to dive into this efficient and precise field, understanding the various types of cutting machines available is crucial. Whether it’s a fiber laser or another type of machine metal cutter, making an informed decision can lead to enhanced productivity and quality in your operations.

How to Get Started with Tube Cutting

Getting started with tube cutting begins with selecting the right easy tube cutting machine that suits your specific needs. Assessing factors such as material type, thickness, and desired precision will guide you in choosing between options like a laser cutting machine or traditional methods. Once you've made your choice, familiarize yourself with the equipment through manuals or tutorials to ensure you maximize its potential.

Importance of Training and Support

Investing in training for operators using a machine metal cutter is essential for safety and efficiency. Proper training ensures that users are well-versed in operating both easy tube cutting machines and laser cutting technology effectively, minimizing errors that could lead to costly mistakes. Additionally, ongoing support from manufacturers can provide valuable insights into maintenance and troubleshooting for your laser cutting machine.

Future Trends in Tube Cutting Technology

The future of tube cutting technology looks bright with innovations like fiber lasers leading the charge towards faster and more efficient processes. As industries continue to demand higher precision and lower operational costs, advancements in automation and smart technology integration are likely to emerge within easy tube cutting machines. Keeping an eye on these trends will not only prepare businesses for upcoming changes but also enhance their competitive edge in a rapidly evolving market.