Introduction

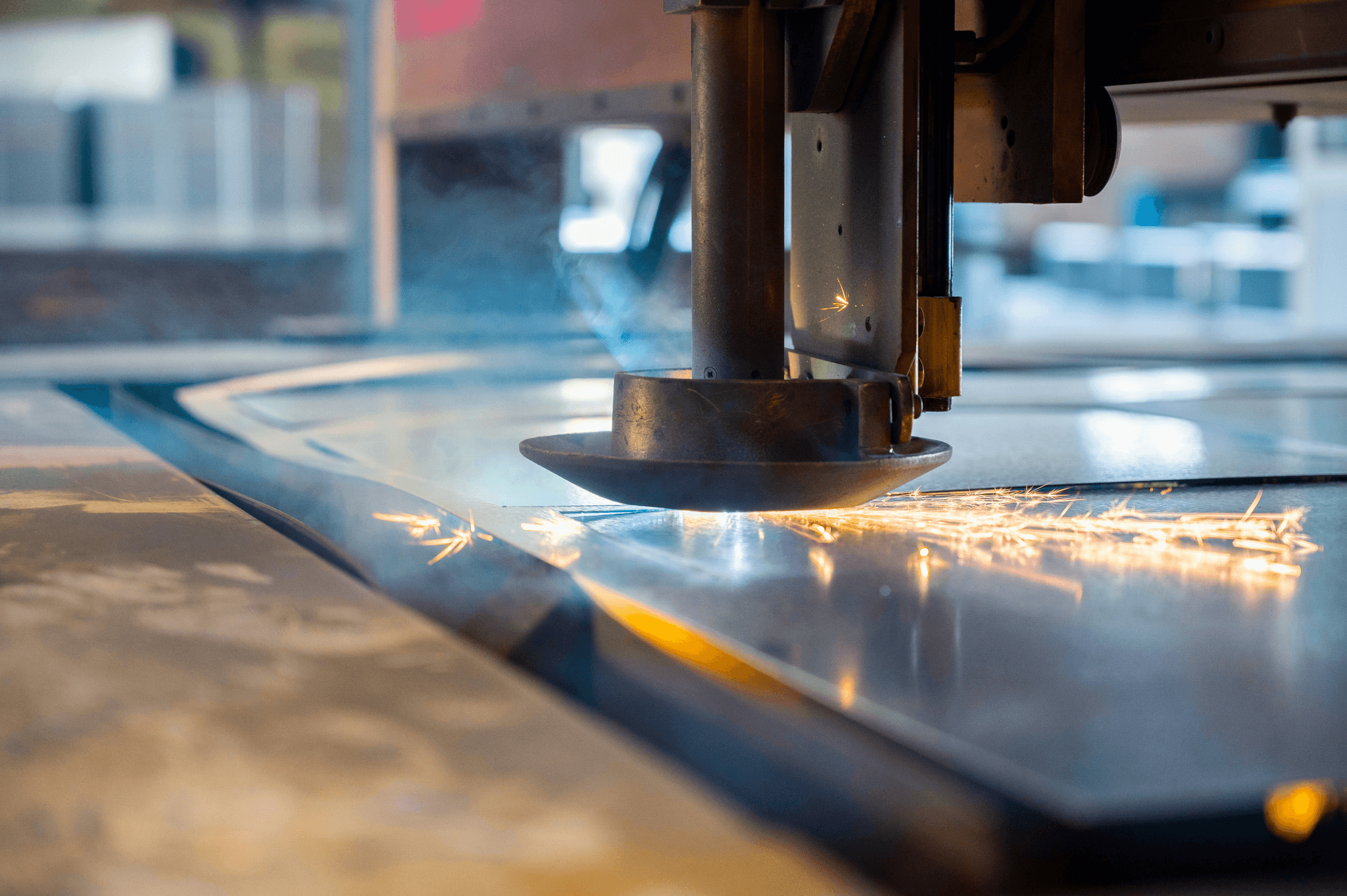

In the realm of modern manufacturing, the Laser Tube Cutting Machine has emerged as a game-changer, revolutionizing how industries approach metal fabrication. This advanced technology utilizes high-powered lasers to cut through various types of metal with remarkable precision and speed. As businesses increasingly seek efficient methods for machine cut metal, laser cutting stands out as a preferred solution for its accuracy and versatility.

What is a Laser Tube Cutting Machine

A Laser Tube Cutting Machine is specifically designed to slice through metal tubes and profiles using focused laser beams. Unlike traditional cutting methods that may produce rough edges or require extensive finishing work, a laser cutter for metal delivers clean cuts with minimal material waste. This makes it an essential tool for industries that demand high-quality results and efficient production processes.

Benefits of Efficient Metal Cutting

The advantages of employing a metal laser cutting machine are numerous and impactful. First and foremost, these machines significantly reduce production time by enabling faster cutting speeds compared to conventional methods. Additionally, they enhance precision in every cut, ensuring consistency across all pieces produced—an invaluable trait when dealing with intricate designs or tight tolerances.

Exploring the Technology Behind Laser Cutting

At the heart of every effective metal cutting laser cutter lies sophisticated technology that harnesses the power of light to achieve superior results. The process involves directing a concentrated beam of light onto the material surface, which melts or vaporizes the metal along predetermined paths. This innovative approach not only enhances efficiency but also opens up new possibilities in design and fabrication that were previously unattainable.

Understanding Laser Tube Cutting

Laser tube cutting is a fascinating field that combines precision engineering with advanced technology. The process utilizes a laser beam to cut through various types of metal, making it an essential tool in modern manufacturing. As industries evolve, the demand for efficient and accurate metal cutting solutions like the Laser Tube Cutting Machine continues to grow.

How Laser Cutters for Metal Work

At the heart of a laser cutter for metal is a focused beam of light that can reach incredibly high temperatures, allowing it to melt or vaporize metal upon contact. This process involves directing the laser beam through optics and mirrors, which help concentrate its energy onto the material being cut. As the machine moves along programmed paths, it creates precise shapes and designs with minimal waste and maximum efficiency.

The versatility of metal cutting machines lasers enables them to handle various materials like steel, aluminum, and brass with ease. By adjusting parameters such as speed, power, and frequency, operators can achieve different thicknesses and finishes tailored to their specific needs. This adaptability makes laser tube cutting machines indispensable in sectors ranging from automotive to aerospace.

Advantages of Metal Laser Cutting Machines

One significant advantage of using a metal laser cutting machine is its unparalleled precision compared to traditional methods like plasma or mechanical cutting. The fine focus of the laser allows for intricate designs without compromising on quality or accuracy. Additionally, this method produces cleaner edges with less burr formation, reducing post-processing requirements.

Another benefit lies in its speed; metal cutting laser cutters can operate at remarkable rates without sacrificing quality. This efficiency translates into shorter lead times for projects and increased productivity on the shop floor. Furthermore, because these machines often require less manual intervention than other forms of metal processing equipment, they help reduce labor costs over time.

Lastly, sustainability plays a crucial role in today’s manufacturing landscape; laser tube cutting minimizes material waste by optimizing cuts more effectively than traditional methods can achieve. This eco-friendly aspect not only appeals to environmentally-conscious businesses but also contributes positively to overall operational costs by maximizing resources.

Key Components of a Laser Cutting System

A complete laser cutting system consists of several key components that work together seamlessly: the laser source generates light energy; optics direct that energy onto the material; motion systems enable precise movement; and control units manage all processes involved in operation. Each element plays an essential role in ensuring optimal performance from your machine cut metal process.

The type of laser source significantly impacts performance—CO2 lasers are popular for their versatility across various metals while fiber lasers excel at processing reflective materials like copper or brass efficiently. Meanwhile, high-quality optics are crucial for maintaining beam focus during operation since even minor discrepancies can lead to inaccuracies in cuts.

Finally, modern control systems equipped with advanced software allow operators greater flexibility when programming complex shapes or patterns into their workflows—ensuring that every piece produced meets exact specifications without unnecessary delays or errors during production runs.

Applications of Laser Tube Cutting Machines

Laser tube cutting machines have revolutionized various industries by providing precise and efficient metal cutting solutions. These machines are not just tools; they are integral to modern manufacturing processes, enabling companies to push the boundaries of design and production. From automotive to aerospace, the applications of laser cutting technology are vast and varied.

Industries Benefiting from Laser Cutting

Numerous industries reap the benefits of laser cutting technology, including automotive, aerospace, construction, and electronics. In the automotive sector, for instance, laser tube cutting machines are used to create intricate parts with high precision that are essential for vehicle safety and performance. Similarly, in aerospace manufacturing, where every ounce counts, a metal laser cutting machine ensures lightweight components without compromising strength or integrity.

The construction industry also utilizes these advanced machines for fabricating steel structures quickly and accurately. Meanwhile, electronics manufacturers rely on laser cutters for metal to produce small but complex parts that require extreme accuracy. As industries continue to innovate and demand higher standards of quality and efficiency, the role of metal cutting laser cutters becomes increasingly critical.

Using Laser Cutters for Precision Engineering

Precision engineering is at the heart of many high-tech industries where tolerances can be measured in microns. The ability of a laser cutter for metal to deliver such accuracy makes it an indispensable tool in this field. Engineers use these machines not only for their ability to cut but also for their capability to engrave intricate designs onto various materials.

With a machine cut metal approach through advanced software integration, designers can create complex geometries that would be impossible with traditional methods. This level of precision allows manufacturers to reduce waste significantly while maintaining high production speeds—a win-win situation! Furthermore, using a metal cutting machine laser enhances repeatability in production runs which is crucial for maintaining quality standards across batches.

The Role of Metal Cutting Laser Cutters in Manufacturing

In manufacturing environments where speed and efficiency are paramount, metal cutting laser cutters play a pivotal role in streamlining operations. These machines enable rapid prototyping and short-run production without sacrificing quality or detail—an essential factor in today's fast-paced market demands. With their ability to cut multiple types of metals—including steel, aluminum, and brass—laser tube cutting machines provide unparalleled versatility.

Moreover, they integrate seamlessly into automated workflows which further enhances productivity levels across manufacturing lines. By utilizing advanced technologies like CNC programming alongside traditional machining methods, businesses can achieve remarkable results with minimal downtime or material waste. As manufacturers continue embracing automation trends within their operations, the reliance on sophisticated equipment like the metal laser cutting machine will only grow stronger.

Choosing the Right Laser Cutting Solutions

When it comes to selecting a laser tube cutting machine, the options can feel overwhelming. Each model boasts various features, technologies, and capabilities tailored for different needs in the metal cutting industry. To make an informed choice, it's essential to consider several key factors that can affect your production efficiency and overall success.

Factors to Consider When Selecting a Machine

One of the primary considerations when choosing a laser cutter for metal is the thickness of the materials you plan to work with. Different machines have varying power levels, which dictate their ability to cut through thick or thin metals effectively. Additionally, think about the types of metal you will be processing; some machines excel with certain materials while struggling with others.

Another important factor is speed and precision; after all, no one wants a machine that takes forever or produces subpar cuts! Look for features such as advanced motion control systems and high-quality optics that enhance both speed and accuracy in your metal cutting processes. Lastly, don’t forget about your budget—balancing cost with performance can help ensure you get the best value from your investment in a metal cutting machine laser.

Comparing Different Laser Cutting Technologies

There are several types of laser cutting technologies available today, each offering unique advantages depending on your specific needs. CO2 lasers are popular for their versatility in cutting various materials but may not be as efficient for thicker metals compared to fiber lasers. On the other hand, fiber lasers are known for their speed and energy efficiency when dealing with metals like stainless steel or aluminum.

When comparing these technologies, consider not just initial costs but also long-term operational expenses such as maintenance and energy consumption associated with each type of machine cut metal. Moreover, think about future scalability—will your chosen technology still serve you well as your business grows? Understanding these distinctions will empower you to select a solution that aligns perfectly with both current demands and future aspirations.

Why Kiant Machinery Stands Out

Kiant Machinery has carved out a niche by consistently delivering top-notch laser tube cutting machines designed specifically for efficiency and precision in metal fabrication. Their commitment to innovation means they stay ahead of trends in laser cutting technology while ensuring compatibility across various applications—be it automotive parts or intricate artistic designs.

Moreover, Kiant Machinery's reputation for excellent customer support sets them apart from competitors; they offer extensive training programs that help operators maximize their use of these sophisticated machines effectively. With an emphasis on durability and performance across their range of products, investing in a Kiant Machinery solution means you're choosing reliability alongside advanced capabilities in the world of metal laser cutting machines.

Enhancing Efficiency with Laser Cutting

In the competitive landscape of manufacturing, enhancing efficiency with laser cutting can significantly impact productivity and profitability. Utilizing a Laser Tube Cutting Machine not only streamlines operations but also ensures precision and consistency in metal cutting processes. By implementing effective techniques and embracing automation, businesses can maximize the output of their metal laser cutting machines.

Techniques to Maximize Output

To truly harness the power of a laser cutter for metal, manufacturers should focus on optimizing their workflows. Start by ensuring that your machine cut metal settings are fine-tuned for each specific material and thickness, allowing for faster cuts without sacrificing quality. Additionally, regularly scheduled maintenance on your metal cutting machine laser will prevent unexpected downtime and keep production running smoothly.

Another effective technique is to utilize nesting software that optimally arranges parts on the sheet material, minimizing waste and maximizing the number of components produced in a single run. This not only saves costs but also enhances overall efficiency in using resources. Lastly, training operators to understand the nuances of their equipment can lead to smarter decisions during production runs, further boosting output from your laser tube cutting machine.

Automating the Metal Cutting Process

Automation has become a game-changer in modern manufacturing, particularly when it comes to enhancing efficiency with laser cutting technologies. Integrating automated systems into your workflow means that your metal cutting laser cutter can operate continuously without human intervention for extended periods—allowing for increased output while freeing up workers for other tasks. This is especially beneficial in high-demand environments where speed is essential.

Moreover, advancements in robotics have led to sophisticated solutions like automated loading and unloading systems that work seamlessly with laser tube cutting machines. These systems ensure that materials are efficiently fed into the machine without delays or errors, thus maintaining optimal production speeds throughout the process. The result? A seamless operation where human error is minimized while maximizing throughput—a win-win situation!

Real-World Success Stories

Many companies have successfully leveraged advanced techniques and automation within their operations using a metal laser cutting machine—and they have some impressive stories to tell! For instance, a leading automotive parts manufacturer implemented an automated system with their laser cutter for metal that resulted in a 30% increase in productivity within just six months! This was achieved through optimized workflows combined with regular maintenance schedules on their equipment.

Another success story comes from an aerospace company that adopted nesting software alongside its existing machinery; they reported reduced material waste by over 25%, translating into significant cost savings annually! Their investment in training staff on how best to use these technologies further contributed to enhanced performance across all departments involved in production processes involving machine cut metal components. These real-world examples showcase how embracing innovation leads directly to improved efficiencies and bottom-line results.

Maintenance and Support for Laser Cutting Machines

Maintaining your laser tube cutting machine is crucial to ensure its longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances the efficiency of your metal cutting processes. A well-maintained metal laser cutting machine can save you time, money, and resources in the long run.

Importance of Regular Maintenance

Regular maintenance of your laser cutter for metal is essential to keep it running smoothly and effectively. Just like any high-performance machine, a metal cutting laser cutter requires routine checks to address wear and tear, ensuring that all components function correctly. Neglecting maintenance can lead to decreased precision in cuts, increased operational costs, and even safety hazards in the workplace.

Moreover, scheduling regular inspections allows you to identify potential issues before they escalate into costly repairs or downtime. This proactive approach not only preserves the integrity of your machine cut metal but also optimizes productivity across your operations. In essence, investing time in maintenance translates into better performance and longer service life for your laser tube cutting machine.

Training and Support from Kiant Machinery

Kiant Machinery understands that having a top-notch metal cutting machine laser is just one part of the equation; knowing how to use it effectively is equally important. They offer comprehensive training programs tailored specifically for users of their laser tube cutting machines. These training sessions cover everything from basic operation techniques to advanced troubleshooting methods, ensuring that operators are well-equipped to maximize their equipment's capabilities.

In addition to training, Kiant Machinery provides ongoing support through dedicated customer service channels. Whether you have questions about specific features or need assistance with complex tasks, their knowledgeable team is just a call away. This commitment to customer support ensures that you can confidently operate your metal cutting laser cutter without fear of encountering insurmountable challenges.

Troubleshooting Common Issues with Metal Cutting Machines

Even with regular maintenance and proper training, issues may occasionally arise with a metal cutting machine laser. Knowing how to troubleshoot common problems can save valuable time during production runs when every second counts. For instance, if you notice inconsistent cut quality or excessive noise during operation, it could indicate misalignment or wear on key components.

Kiant Machinery provides detailed troubleshooting guides along with their machines that help users identify problems quickly and efficiently. By following these guidelines or consulting with a support representative when needed, operators can resolve issues promptly without extensive downtime or loss of materials during production runs. Ultimately, being prepared for common challenges ensures that your operations remain smooth while maximizing the effectiveness of your laser cutter for metal.

Conclusion

In conclusion, the world of laser tube cutting has revolutionized how industries approach metal fabrication. The efficiency and precision offered by a metal laser cutting machine are unparalleled, making it an invaluable asset in modern manufacturing processes. Whether you’re looking to enhance production capabilities or achieve intricate designs, investing in a laser cutter for metal is a decision that pays off.

Key Takeaways on Laser Tube Cutting

Laser tube cutting machines provide exceptional accuracy and speed, allowing for intricate designs without compromising on quality. The benefits of using a metal cutting laser cutter include reduced waste and lower operational costs, making them ideal for businesses aiming to maximize their efficiency. Ultimately, understanding the technology behind these machines can significantly enhance your production capabilities.

Future Trends in Metal Laser Cutting

The future of metal laser cutting is bright, with advancements in automation and artificial intelligence poised to take center stage. As technology evolves, we can expect even faster processing speeds and improved precision from machine cut metal solutions. Additionally, the integration of IoT (Internet of Things) will enable real-time monitoring and predictive maintenance for laser cutting systems, ensuring optimal performance.

Making an Informed Purchase Decision

When considering a purchase of a metal cutting machine laser, it’s crucial to evaluate your specific needs against the features offered by various models. Factors such as material thickness, operational volume, and budget should guide your choice to ensure you select the right equipment for your business. By comparing different technologies and understanding what sets brands like Kiant Machinery apart, you can make an informed decision that aligns with your long-term goals.