Introduction

In the world of modern manufacturing and design, laser cutting machines have emerged as indispensable tools. Whether you're an artist looking to create intricate designs or a business aiming to streamline production, finding the right laser cutting machine for sale can make all the difference. With various options available, understanding how to choose the perfect machine is crucial for maximizing efficiency and achieving high-quality results.

Discover the Laser Cutting Machine for You

When searching for a laser metal cutting machine, it’s essential to assess your specific needs and applications. Different projects may require varying capabilities, such as power levels or precision cuts, making it vital to explore what each metal cutting laser cutter has to offer. By identifying your unique requirements, you can narrow down your choices and find a cutting machine laser that fits seamlessly into your workflow.

Key Features to Consider

Before making a decision on a laser machine, consider key features that will impact performance and usability. Factors like wattage affect cutting speed and material compatibility, while precision plays a significant role in achieving clean edges and detailed designs. Additionally, software compatibility is crucial; ensure that the metal cutting machine laser you choose integrates smoothly with your existing systems for an efficient setup.

Where to Find Top Options

Finding reputable suppliers is paramount when searching for a reliable laser cutting machine for sale. Established brands often provide better support and warranties, ensuring peace of mind with your investment in a metal cutting laser cutter. Online marketplaces, industry trade shows, and specialized machinery websites are excellent places to discover top options tailored to your needs.

Understanding Laser Cutting Technology

Laser cutting technology has revolutionized the way we approach manufacturing and design, making it an essential tool for many industries. Whether you’re looking for a laser cutting machine for sale or simply want to understand how these machines work, grasping the fundamentals will enhance your decision-making process. In this section, we’ll break down the mechanics of laser cutting, its benefits, and how it compares to other techniques.

How Laser Cutting Works

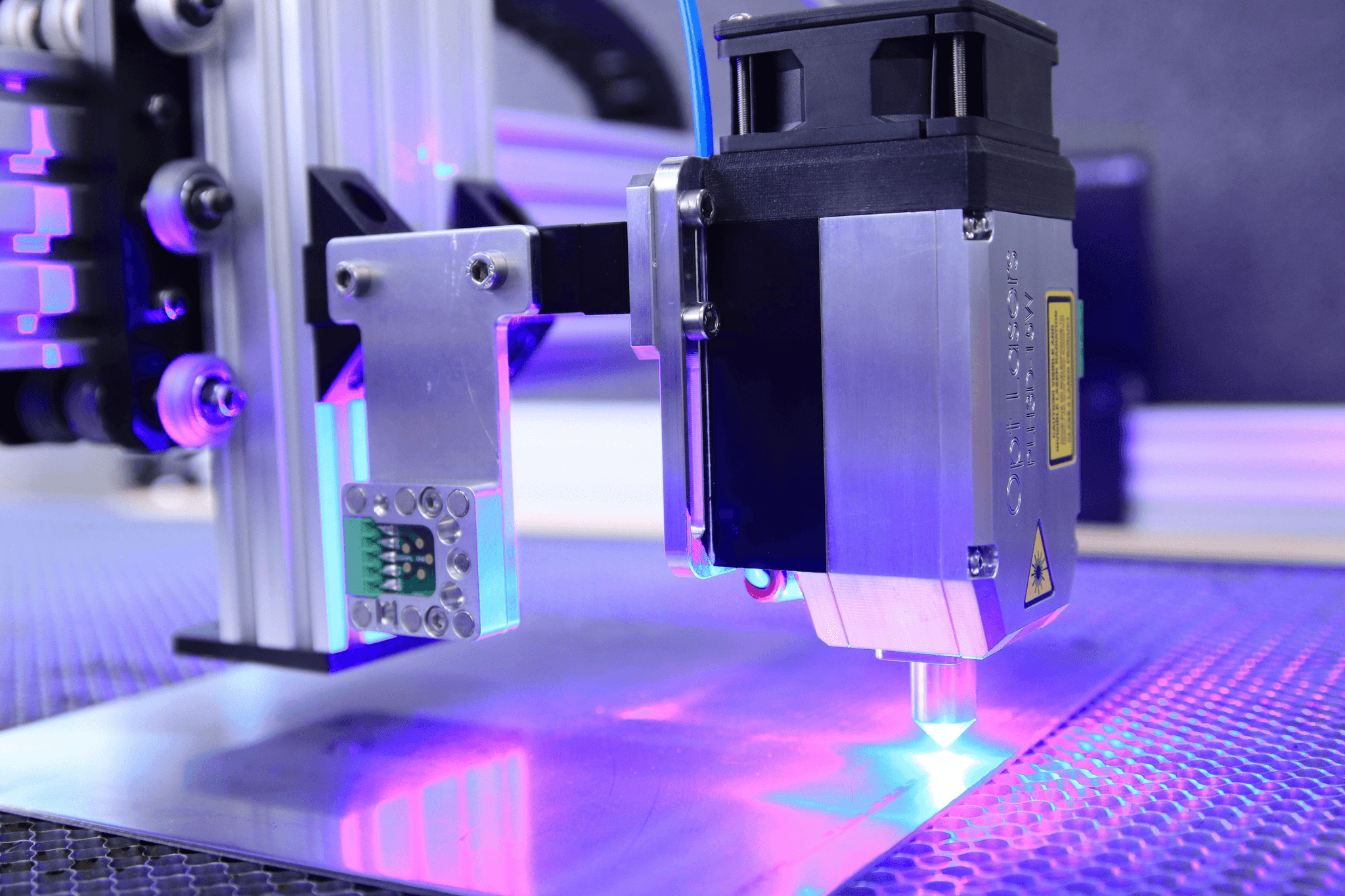

At its core, a laser cutting machine uses focused light beams to cut through various materials with precision and speed. The process involves directing a high-powered laser beam onto the material's surface, which melts or vaporizes it at the point of contact. This method allows for intricate designs and shapes that would be difficult to achieve with traditional metal cutting machines.

The operation typically involves a computer numerical control (CNC) system that guides the laser along predetermined paths based on digital designs. This automation not only enhances accuracy but also significantly reduces human error in the manufacturing process. As you explore options like a metal cutting laser cutter, understanding this mechanism helps you appreciate why these machines are so sought after in industries ranging from automotive to fashion.

Benefits of Using a Laser Machine

Investing in a laser machine offers numerous advantages over conventional methods of cutting materials. First and foremost is precision; these machines provide incredibly accurate cuts with minimal kerf width, ensuring that your final product meets exact specifications every time. Additionally, using a metal cutting machine laser minimizes waste because of its efficient use of material.

Another significant benefit is versatility; laser cutters can handle various materials such as metals, plastics, wood, and even textiles without needing major adjustments or different tools. This adaptability makes them invaluable in workshops where multiple types of projects are undertaken regularly. Lastly, operating costs tend to be lower over time due to reduced labor needs and less material wastage compared to traditional methods.

Comparing Different Laser Cutting Techniques

When considering which type of technology suits your needs best—whether it's CNC or CO2 lasers—it's essential to weigh their strengths and weaknesses against your specific requirements. CNC lasers are known for their precision and speed when working on metal sheets but can be more expensive upfront than CO2 options designed primarily for non-metal materials like plastic or wood.

CO2 lasers often come at lower initial costs while still providing excellent quality cuts for softer materials; however, they may not perform as well on thicker metals compared to their CNC counterparts. Ultimately, choosing between these technologies depends on what you plan to cut most frequently—if you're leaning toward acquiring a metal cutting machine laser specifically for heavy-duty tasks like industrial fabrication, investing in a CNC model might be worth considering.

Types of Laser Cutting Machines

Overview of Laser Metal Cutting Machines

Laser metal cutting machines are specialized tools designed to slice through various metals with precision and speed. Utilizing high-powered lasers, these machines can cut through materials like steel, aluminum, and brass with remarkable accuracy. Whether you're in aerospace, automotive, or creative industries, investing in a metal cutting laser cutter can significantly enhance your production capabilities.

Advantages of Metal Cutting Laser Cutters

One of the standout benefits of metal cutting laser cutters is their ability to produce clean edges without the need for secondary finishing processes. This not only saves time but also reduces material waste—an essential factor for businesses looking to optimize their operations. Additionally, these machines offer unparalleled versatility; you can switch between different materials and thicknesses without extensive reconfiguration.

Choosing Between CNC and CO2 Laser Machines

When selecting a cutting machine laser for your needs, you'll often find yourself deciding between CNC (Computer Numerical Control) machines and CO2 lasers. CNC machines are known for their precision and ability to handle complex designs effectively; however, CO2 lasers excel at cutting non-metal materials like wood and acrylic while still being capable of handling metals with appropriate settings. Ultimately, your choice will depend on your specific projects—if you're focused on metalwork exclusively, a dedicated metal cutting machine laser might be the way to go.

Key Features of a Cutting Machine Laser

When considering a cutting machine laser, several key features stand out that can greatly influence your purchase decision. From power and wattage to precision and speed, each aspect plays a crucial role in determining the effectiveness of your laser metal cutting machine. Additionally, software compatibility and integration can enhance the overall user experience, making it essential to evaluate these features carefully.

Power and Wattage Considerations

Power and wattage are fundamental aspects of any laser cutting machine for sale. The wattage determines how effectively the metal cutting laser cutter can slice through various materials; higher wattage typically means faster cutting speeds and the ability to handle thicker metals. When shopping for a metal cutting machine laser, it's important to assess your specific needs—if you’re working with thicker materials or require intricate designs, opting for a higher-powered model will be beneficial.

Moreover, keep in mind that different applications may require varying levels of power; for instance, detailed engraving might not need as much power as heavy-duty cutting. Understanding these nuances will help you choose the right laser machine price point while ensuring you get the most suitable equipment for your projects. Remember that investing in quality power specifications now could save you time and money in future jobs.

Precision and Speed Factors

Precision is another critical feature when selecting a metal cutting laser cutter; after all, no one wants jagged edges on their meticulously crafted designs! A high-quality laser cutting machine excels at delivering clean cuts with minimal kerf width, which is essential for achieving professional results. Speed also plays an important role—faster machines can increase productivity but should not compromise on accuracy.

When comparing options, look at specifications such as maximum speed (measured in mm/min) alongside precision ratings (often expressed as tolerance levels). This combination will give you insight into how well the machine performs under various conditions while ensuring that your projects meet industry standards. Ultimately, balancing precision with speed ensures that you maintain quality without sacrificing efficiency.

Software Compatibility and Integration

The software compatibility of your chosen metal cutting machine laser is crucial for seamless operation within your workflow. Many modern machines come equipped with advanced software solutions designed to optimize design layouts and improve overall efficiency during production runs. When evaluating options, consider whether the software is compatible with popular design programs like AutoCAD or SolidWorks—this integration can save significant time by streamlining processes from design to execution.

Additionally, user-friendly interfaces are essential; no one wants to spend hours deciphering complicated controls when they could be creating stunning pieces! Look for machines that offer intuitive controls along with comprehensive support resources like tutorials or customer service assistance if needed. By prioritizing software compatibility alongside hardware features, you're setting yourself up for success in every project.

Pricing Your Laser Cutting Machine

When it comes to investing in a laser cutting machine, understanding the price ranges can feel like navigating a maze. The cost of a laser cutting machine for sale can vary significantly based on its capabilities, size, and technology used. Whether you’re eyeing a compact model for small projects or an industrial-grade laser metal cutting machine, knowing what to expect in terms of pricing will help you make an informed decision.

Understanding Laser Machine Price Ranges

Laser machines come in various price brackets, typically ranging from a few thousand dollars to well over $100,000 for high-end models. Entry-level metal cutting laser cutters designed for hobbyists may start around $2,000 to $5,000. In contrast, professional-grade machines that offer advanced features and higher power output can cost anywhere from $20,000 to $100,000 or more.

For those looking specifically at metal cutting machines lasers, the average price tends to be higher due to the precision and strength required for effective operation. Additionally, factors like brand reputation and warranty offerings can also influence the overall pricing landscape. Understanding these ranges will give you clarity on what fits within your budget while still meeting your project needs.

Factors Influencing Cost

Several factors come into play when determining the cost of a laser cutting machine. First and foremost is the type of technology used; CO2 lasers are generally more affordable than fiber lasers but may not offer the same level of efficiency in certain materials. Other considerations include power levels (measured in watts), which directly correlate with the thickness of material that can be cut effectively by your chosen metal cutting laser cutter.

The build quality and additional features such as automated loading systems or advanced software integration also contribute significantly to pricing variations among different models. Lastly, whether you're purchasing new or considering refurbished options will impact your overall expenditure as well—new machines often come with warranties that refurbished ones might not have. Being aware of these influencing factors will enable you to allocate resources wisely without compromising on quality.

Where to Find Affordable Options

Finding affordable options for your desired cutting machine laser doesn’t have to feel like searching for buried treasure! Start by exploring reputable online marketplaces where various sellers list their laser cutting machines for sale—often at competitive prices compared to traditional retail stores. Websites specializing in industrial equipment frequently feature deals that could save you hundreds or even thousands on top-notch machinery.

Don’t overlook local distributors who might offer promotions or discounts on stock items as well; sometimes they have sales events that allow customers access to lower prices directly from manufacturers’ inventories. Additionally, consider joining forums or groups dedicated to fabrication and machining where members often share leads on great deals or second-hand equipment available at reasonable rates—after all, one person’s upgrade could be another's golden opportunity!

Finding a Trusted Supplier

When it comes to investing in a laser cutting machine for sale, finding a reputable supplier is crucial for ensuring quality and reliability. A trustworthy supplier can provide you with not just the equipment but also ongoing support and service, which are essential for maintaining your metal cutting machine laser. With so many options available, it's important to choose a supplier that stands out in the industry.

Why Choose Kiant Machinery

Kiant Machinery has established itself as a leader in the field of laser technology, particularly when it comes to laser metal cutting machines. Their commitment to innovation and customer satisfaction makes them an ideal choice for anyone looking to purchase a metal cutting laser cutter. With an extensive range of products and exceptional after-sales support, Kiant Machinery ensures that you get the best value for your investment in cutting machine lasers.

Their focus on quality means that every laser machine they offer undergoes rigorous testing before reaching customers. This dedication not only enhances performance but also extends the lifespan of your equipment—key factors when considering the overall cost of ownership. Choosing Kiant Machinery means you're partnering with a brand that prioritizes excellence at every step of your purchasing journey.

Benefits of Buying from Established Brands

Purchasing from established brands like Kiant Machinery offers numerous benefits that can significantly enhance your experience with your new laser cutting machine for sale. For starters, these brands often have years—if not decades—of experience in manufacturing high-quality machines designed specifically for various applications including metal cutting tasks. This expertise translates into superior product reliability and performance.

Additionally, established brands typically provide comprehensive warranties and customer support services that ensure you're never left hanging if something goes awry with your equipment. Their reputation often brings peace of mind because you know you're investing in a product backed by positive reviews and proven results over time. Plus, many established suppliers offer training sessions or resources to help you maximize the potential of your new metal cutting machine laser.

Reviews and Testimonials from Other Users

Before making any significant purchase like a laser cutting machine for sale, it's wise to check out reviews and testimonials from other users who have firsthand experience with specific models or brands such as Kiant Machinery's offerings. Many satisfied customers rave about their experiences with both the machinery's performance and the level of customer service received during their buying journey—two critical factors when selecting a reliable supplier.

User reviews often highlight key features such as precision cuts, ease of use, speed efficiency, and overall satisfaction with their metal cutting laser cutter investments. Additionally, testimonials can provide insight into how well these machines hold up over time under various working conditions—which is invaluable information when weighing options between different models or suppliers.

In conclusion, taking the time to research trusted suppliers like Kiant Machinery will ultimately lead you toward making an informed decision on purchasing your next cutting machine laser while ensuring you receive excellent value along the way.

Conclusion

In the realm of precision manufacturing, choosing the right laser cutting machine can significantly impact your productivity and output quality. Whether you're eyeing a laser metal cutting machine for intricate designs or a robust metal cutting laser cutter for heavier tasks, understanding your needs is crucial. With various options available, from budget-friendly models to high-end machines, it's essential to weigh all factors before making a commitment.

Final Thoughts on Choosing a Laser Cutter

When selecting a cutting machine laser, consider not only your current projects but also future applications that may arise. The versatility of a laser machine can open doors to new opportunities in design and production, making it an invaluable asset for any workshop. Remember that investing in a quality laser metal cutting machine now can save you time and money down the road as you expand your capabilities.

Tips for Maintenance and Longevity

To ensure the longevity of your metal cutting machine laser, regular maintenance is key. This includes routine cleaning, checking alignment, and ensuring that all components are functioning optimally. By following these simple practices, you can extend the life of your equipment while maintaining peak performance—after all, nobody wants to deal with unexpected downtime when working on critical projects!

Making an Informed Purchase Decision

Before diving into the world of laser cutting machines for sale, take time to research various models and their specifications thoroughly. Compare prices across different suppliers while considering factors like warranty coverage and customer support; this could be the difference between a good deal and a great one! Ultimately, by arming yourself with knowledge about features like power levels or software compatibility, you'll be well-equipped to make an informed purchase decision tailored to your unique needs.