Introduction

In the realm of modern manufacturing, laser cutting technology has revolutionized the way we approach metal fabrication. Among these innovations, fiber laser cutting stands out for its precision and efficiency, making it a go-to choice for many industries. Whether you're a small workshop or a large-scale manufacturing facility, understanding what fiber laser cutting entails is essential for optimizing your operations.

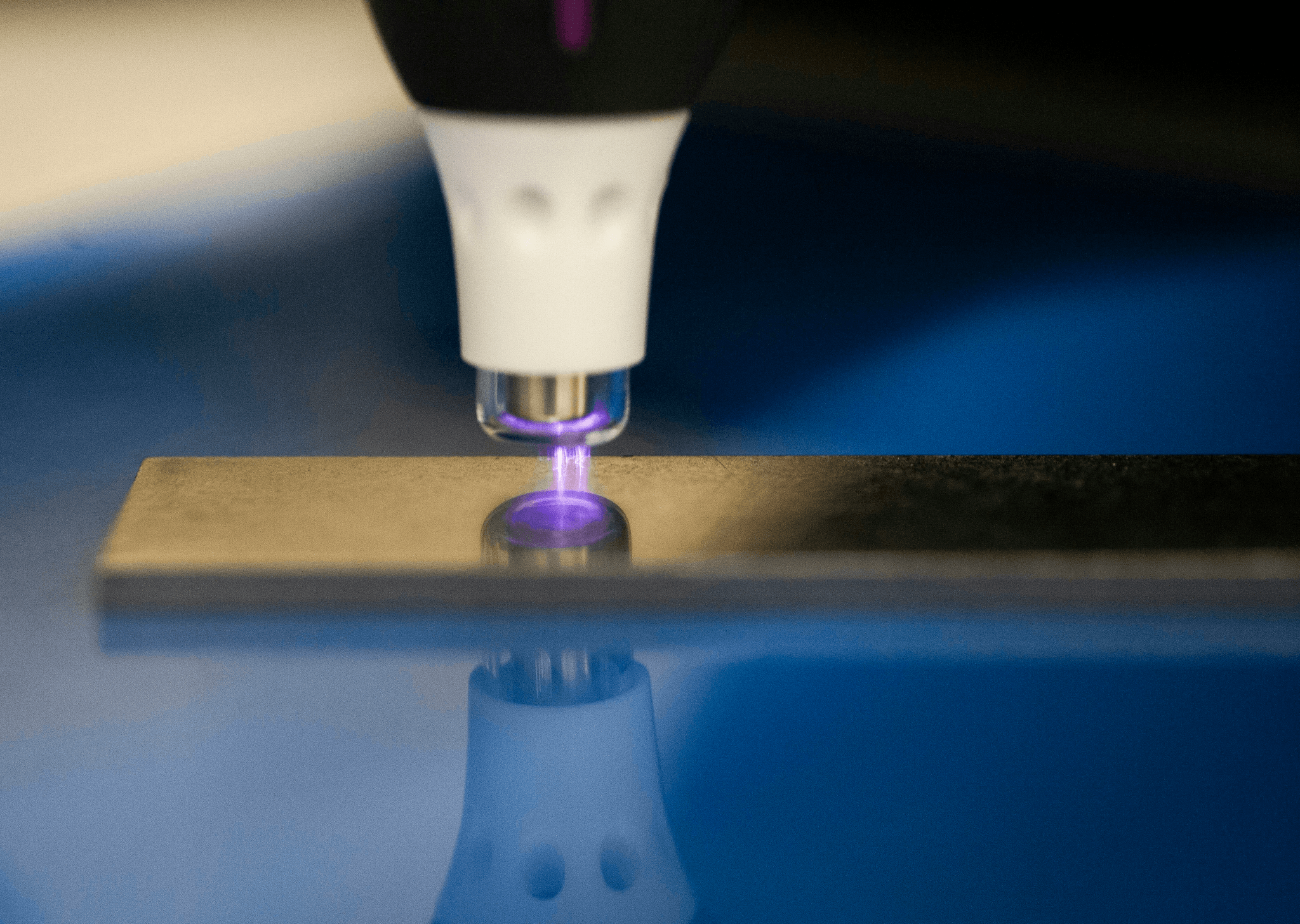

What is Fiber Laser Cutting?

Fiber laser cutting utilizes a high-powered beam of light generated by fiber optics to cut through various materials, particularly metals. This method is distinct from traditional metal cutting processes due to its ability to produce clean edges and intricate designs with minimal waste. The technology behind a laser cutter allows for rapid processing speeds while maintaining exceptional accuracy, making it ideal for machine cut metal applications.

Benefits of Using a Laser Cutter

The benefits of using a metal cutting laser cutter are numerous and compelling. First and foremost, these machines offer unparalleled precision, which translates into higher-quality finished products and less material wastage. Additionally, the speed at which a laser metal cutting machine operates significantly reduces production times compared to conventional methods, allowing businesses to meet tight deadlines without compromising quality.

Choosing the Right Metal Cutting Machine

The type of materials you plan to work with—such as thickness and composition—will dictate the capabilities required from your laser iron cutting machine. Moreover, factors like software compatibility and overall budget will play crucial roles in ensuring you invest in the right equipment that aligns with your operational goals.

Overview of Fiber Laser Cutting Machines

Fiber laser cutting machines have revolutionized the metal fabrication industry, offering unparalleled precision and speed. Unlike traditional methods, a laser cutter utilizes a focused beam of light to slice through materials with remarkable accuracy. This technology has made the laser metal cutting machine a go-to solution for businesses looking to enhance their production capabilities.

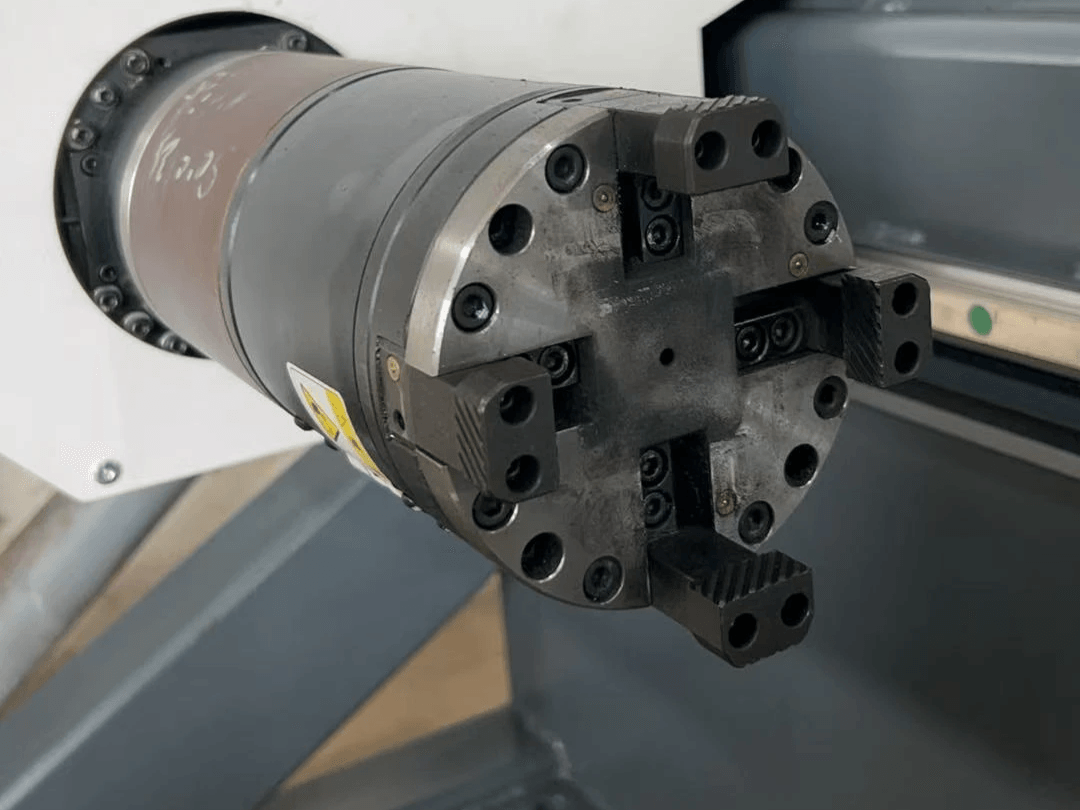

Key Features of Laser Metal Cutting Machines

The key features of a laser metal cutting machine are what set them apart from conventional options. For starters, these machines boast high-speed cutting capabilities that drastically reduce production time while maintaining exceptional quality. Additionally, they can handle various materials—including steel, aluminum, and even intricate designs—making them versatile tools in any workshop.

Another standout feature is the ability to achieve intricate cuts without the need for extensive tooling changes or setups. This flexibility allows fabricators to produce complex shapes and designs efficiently, making the metal machine cutter an essential asset in modern manufacturing processes. Plus, many models come equipped with advanced software that enhances user experience and operation efficiency.

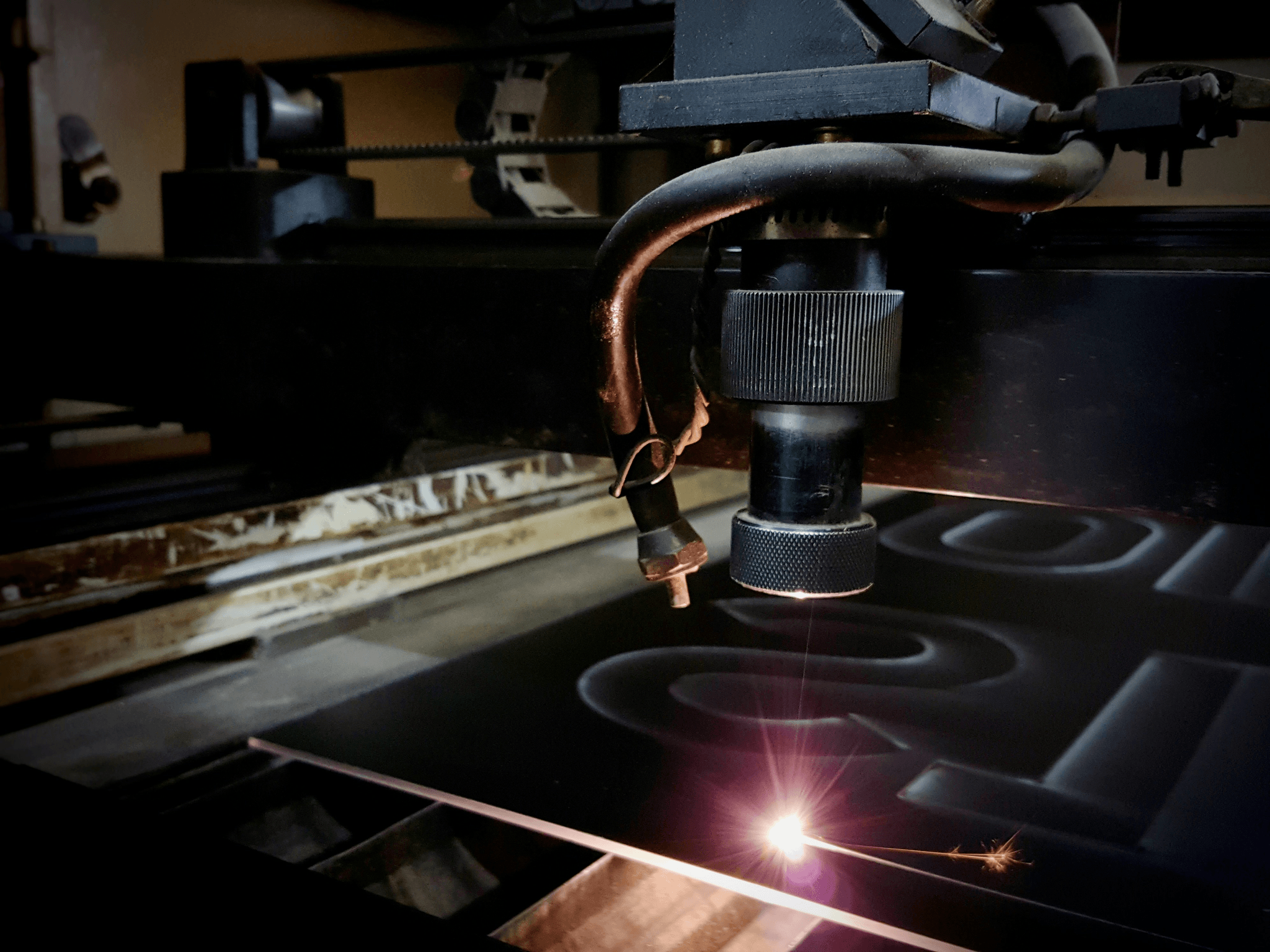

Comparison with Traditional Cutting Methods

When comparing fiber laser cutting to traditional cutting methods like plasma or mechanical saws, it's clear why many are making the switch to a metal cutting laser cutter. Traditional methods often result in rough edges and require secondary processes for finishing touches; however, a laser cutter provides clean cuts right off the bat. The precision offered by these machines means less material waste and reduced costs over time.

Moreover, fiber lasers can cut through thicker materials more effectively than older technologies without compromising speed or quality. In contrast to mechanical cutters that wear down over time and require frequent blade replacements, a well-maintained fiber laser can operate efficiently for years with minimal maintenance needs. This durability makes investing in a machine cut metal solution not only practical but also economically wise.

Applications in Metal Fabrication

The applications of fiber laser cutting machines in metal fabrication are vast and varied. Industries ranging from automotive to aerospace rely on these machines for everything from prototyping parts to producing large-scale components efficiently. Whether it’s creating custom brackets or intricate designs for artistic projects, a metal cutting machine laser can handle it all with ease.

Additionally, as industries continue to innovate and evolve, so too does the demand for precise cuts that only a fiber laser can deliver. The versatility of these machines allows fabricators to cater to diverse client needs while ensuring high-quality results every time. With advancements in technology continually pushing boundaries, it's clear that fiber lasers will play an increasingly pivotal role in shaping the future of manufacturing.

Top Fiber Laser Cutting Machines for Metal

Bystronic ByStar Fiber

The Bystronic ByStar Fiber is a standout in the realm of laser cutting technology, renowned for its exceptional performance and reliability. This laser metal cutting machine is designed to handle a variety of materials with ease, making it perfect for those who require versatility in their operations. With its advanced automation features, the ByStar Fiber can significantly reduce downtime and maximize output, ensuring that your metal machine cutter remains efficient throughout its lifecycle.

Equipped with intelligent software and a user-friendly interface, this machine cut metal with remarkable precision. The ByStar Fiber excels in cutting thicker materials without compromising on quality, making it an ideal choice for heavy-duty applications. If you're searching for a robust laser iron cutting machine that can keep pace with your production demands, look no further than the Bystronic ByStar Fiber.

TRUMPF TruLaser Series

The TRUMPF TruLaser Series offers a range of models tailored to meet diverse needs within the metal fabrication industry. Known for their high-speed processing capabilities, these laser cutters are engineered to provide unparalleled accuracy while maintaining impressive throughput rates. The TruLaser Series stands out due to its innovative features that optimize energy consumption—making it not just powerful but also environmentally friendly.

With options available for both thin and thick materials, this series ensures that users can achieve superior results regardless of their specific requirements. The integration of smart technologies allows operators to monitor performance metrics easily, enhancing overall efficiency during operation. For businesses looking for a versatile and reliable metal cutting machine laser solution, the TRUMPF TruLaser Series is hard to beat.

Amada ENSIS Series

The Amada ENSIS Series represents the pinnacle of innovation in fiber laser technology, offering unmatched flexibility and precision in laser cutting applications. This series utilizes advanced beam control technology that enables consistent quality across various material types and thicknesses—ideal for any project requiring intricate designs or high levels of detail. Whether you’re working with stainless steel or aluminum, this laser cutter guarantees exceptional results every time.

One notable feature is its ability to automatically adjust parameters based on material characteristics—saving time while ensuring optimal performance during each cut session. Additionally, users appreciate the intuitive interface that simplifies operation without sacrificing capability; even those new to using a metal machine cutter will find it easy to navigate through complex tasks efficiently. For anyone serious about investing in a top-tier laser iron cutting machine, the Amada ENSIS Series should be at the forefront of your considerations.

Advantages of the Kiant Machinery Laser Cutter

When it comes to choosing a metal cutting machine laser, the Kiant Machinery Laser Cutter stands out for several compelling reasons. This machine is designed not only for precision but also for efficiency in cutting various metal types. Whether you're working with thin sheets or thicker materials, this laser iron cutting machine promises to deliver results that are both accurate and swift.

Precision and Efficiency in Cutting

The Kiant Machinery Laser Cutter excels in delivering high precision cuts, making it an ideal choice for intricate designs and detailed work. With advanced technology integrated into its design, this laser metal cutting machine minimizes waste and maximizes output, ensuring that every cut is clean and exact. Users often find that they can achieve tighter tolerances than with traditional methods, which makes a significant difference in projects requiring meticulous attention to detail.

Moreover, the efficiency of this metal cutting laser cutter allows for faster production times without compromising quality. It can handle various materials with ease, from mild steel to stainless steel, ensuring versatility across different applications. Thus, investing in a Kiant Machinery Laser Cutter not only enhances your workshop's capabilities but also boosts overall productivity.

User-Friendly Interface and Operation

One of the standout features of the Kiant Machinery Laser Cutter is its user-friendly interface designed for operators of all skill levels. The intuitive controls make it easy to set up jobs quickly without extensive training—ideal for businesses looking to streamline operations without sacrificing quality or safety. Even those new to operating a laser cutter will find themselves comfortable navigating through tasks efficiently.

Additionally, this metal machine cutter comes equipped with advanced software that simplifies design uploads and adjustments on-the-fly. This means you can spend less time fiddling with settings and more time focusing on what matters: producing high-quality cuts. With such ease of operation, it's no wonder that many users rave about their experience with this laser cutting marvel.

Comprehensive Support and Training

Purchasing a laser iron cutting machine is an investment not just in equipment but also in support systems that ensure optimal performance over time. Kiant Machinery offers comprehensive training programs tailored specifically for their users; these programs cover everything from basic operation to troubleshooting common issues you might encounter along the way. This commitment to support helps users feel confident when operating their new machinery.

Moreover, should any questions arise post-purchase, their dedicated customer service team is always ready to assist—whether you need technical advice or operational tips regarding your metal cutting machine laser setup. Such extensive support ensures that you're never left stranded after making such an important investment into your business capabilities. Ultimately, choosing a Kiant Machinery Laser Cutter means gaining access not only to exceptional technology but also invaluable resources aimed at maximizing your success.

Factors to Consider When Buying a Laser Cutter

When you're on the hunt for a laser cutter, several factors come into play that can make or break your purchase. Understanding what you need from a laser metal cutting machine is crucial for ensuring it meets your operational requirements. From the types of materials you plan to cut to the budget constraints, each aspect plays a significant role in your decision-making process.

Material Thickness and Types

One of the first considerations when selecting a metal cutting machine laser is the thickness and types of materials you'll be working with. Different laser cutters have varying capabilities when it comes to cutting through different gauges of metal, so it's essential to know what you plan to work with before making an investment. For instance, if you're primarily dealing with thick steel plates, you'll want a robust laser iron cutting machine that can handle those demands without breaking a sweat.

Additionally, consider whether you'll be working with other materials like aluminum or copper; not all machines are created equal in this regard. Some machines excel at cutting thin sheets but struggle with thicker stock or different alloys. Therefore, understanding your material needs will help narrow down your options significantly.

Software Compatibility

In today’s high-tech world, having software compatibility is crucial for any metal machine cutter you choose. The best laser cutters come equipped with advanced software that allows for seamless integration into existing workflows and enhances overall efficiency during operation. Before buying, ensure that the chosen model supports popular design software or has its own user-friendly interface for easy programming.

Moreover, consider how often you'll need software updates and whether those updates come at an additional cost. A good laser cutter should not only provide compatibility but also offer ongoing support and upgrades as technology evolves—after all, nobody wants their shiny new laser cutting toy becoming obsolete too soon!

Budget and Total Cost of Ownership

While it might be tempting to go for the cheapest option available when looking at metal cutting lasers, remember that initial price isn't everything; total cost of ownership matters too! This includes maintenance costs, consumables like lenses and nozzles, as well as potential downtime due to repairs or inefficiencies in older models. Investing in a quality machine cut metal can save you money in the long run by reducing these hidden expenses.

Additionally, weigh out financing options and warranties offered by manufacturers; they can significantly impact your budget over time. A more expensive but reliable machine could end up being more cost-effective than opting for a budget-friendly model that requires frequent repairs or replacements down the line.

Maintenance Tips for Fiber Laser Cutting Machines

Maintaining your fiber laser cutting machine is crucial to ensuring its longevity and performance. Regular upkeep not only enhances the efficiency of your laser metal cutting machine but also minimizes downtime and costly repairs. Here are some essential maintenance tips to keep your metal cutting laser cutter in top shape.

Regular Cleaning Practices

Regular cleaning practices are vital for the optimal performance of any laser cutter, especially when it comes to a laser iron cutting machine. Dust, debris, and metal shavings can accumulate around the machine and interfere with its operation, leading to less precise cuts and potential damage. Make it a routine to clean the work area, including the lenses and mirrors of your metal machine cutter, ensuring that they remain free from contaminants that could affect cutting quality.

Additionally, keeping the water cooling system clean is essential for preventing overheating in your laser metal cutting machine. Regularly check for any blockages or buildup in hoses and filters to maintain efficient cooling performance. A well-maintained environment will not only prolong the life of your equipment but also ensure that you achieve consistent results with every cut.

Importance of Software Updates

Staying up-to-date with software updates is another critical aspect of maintaining a metal cutting machine laser. These updates often include improvements in functionality, new features, and enhancements that can significantly boost productivity and precision in laser cutting tasks. Failing to update can lead to compatibility issues or missed opportunities for optimizing your workflow.

Moreover, updated software may provide better security against potential cyber threats that could compromise sensitive operational data or disrupt production processes. Keeping your software current ensures that you maximize the full capabilities of your laser cutter while minimizing risks associated with outdated technology. So don’t forget—regularly check for updates!

Troubleshooting Common Issues

Even with diligent maintenance practices, issues may still arise from time to time with your fiber laser cutting machines; however, knowing how to troubleshoot common problems can save you both time and money in repairs. For instance, if you notice uneven cuts or excessive dross on edges when using a metal cutting laser cutter, it could be due to incorrect settings or worn-out components like lenses or nozzles.

Another common issue involves misalignment during operation; this can often be resolved by recalibrating the optical path or checking mechanical components such as belts and gears within the system. Familiarizing yourself with troubleshooting techniques will empower you as an operator—enabling quicker resolutions without always relying on technical support services.

Conclusion

In conclusion, laser cutting technology has revolutionized the metal fabrication industry, offering unparalleled precision and efficiency. The versatility of a laser cutter allows for intricate designs and complex shapes that traditional methods simply can't match. With a wide range of options available, including advanced models like the laser iron cutting machine, it’s clear that investing in these machines can significantly enhance production capabilities.

Key Takeaways on Laser Cutting Machines

When considering a laser metal cutting machine, it’s essential to recognize the key benefits they bring to the table. First and foremost, these machines provide exceptional accuracy while reducing material waste—a win-win for any operation. Additionally, features such as user-friendly interfaces and compatibility with various software make them an indispensable part of modern metal fabrication processes.

The Future of Metal Fabrication

The future of metal fabrication is undoubtedly intertwined with advancements in laser cutting technology. As industries continue to evolve and demand more precise components at faster rates, metal cutting machines will play a crucial role in meeting these challenges head-on. With ongoing innovations in speed, efficiency, and automation, the landscape of manufacturing will be shaped by the capabilities of machines like the metal machine cutter.

Investing in Quality and Technology

Investing in quality when selecting a laser cutter is not merely about upfront costs; it’s about long-term value and performance. High-quality machines often come with better support services and training opportunities that can drastically reduce downtime during operations. Embracing advanced technologies like those found in modern laser iron cutting machines ensures your business remains competitive while maximizing productivity.