Introduction

In the world of manufacturing and design, understanding laser cutting machine costs is crucial for businesses aiming to enhance their production capabilities. These machines have revolutionized various industries with their precision and efficiency, but navigating the pricing landscape can be daunting. With a wide array of options available, from entry-level models to high-end industrial laser cutters, it’s vital to grasp what influences these costs.

Understanding Laser Cutting Machine Costs

When considering a laser cutting machine, it's essential to recognize that prices can vary significantly based on several factors. The initial investment in a laser cutter often reflects its capabilities, including power output and technology used. By breaking down the components that contribute to laser machine cost, potential buyers can make informed decisions tailored to their specific needs.

Key Factors Influencing Prices

Several key factors play a role in determining the price of laser cutting machines. First and foremost is the power and performance specifications; higher wattage typically leads to increased costs due to enhanced cutting speed and material versatility. Additionally, brand reputation and reliability can significantly impact pricing—well-known manufacturers often charge a premium for proven quality and support.

Different Types of Laser Cutting Machines

Laser cutting machines come in various types, each designed for specific applications and budgets. Entry-level models are perfect for small businesses or hobbyists looking to experiment without breaking the bank, while mid-range industrial laser cutters cater to more demanding production environments. For those seeking top-tier performance with advanced features, high-end professional systems offer unparalleled precision but at a higher price point.

Overview of Laser Cutting Technology

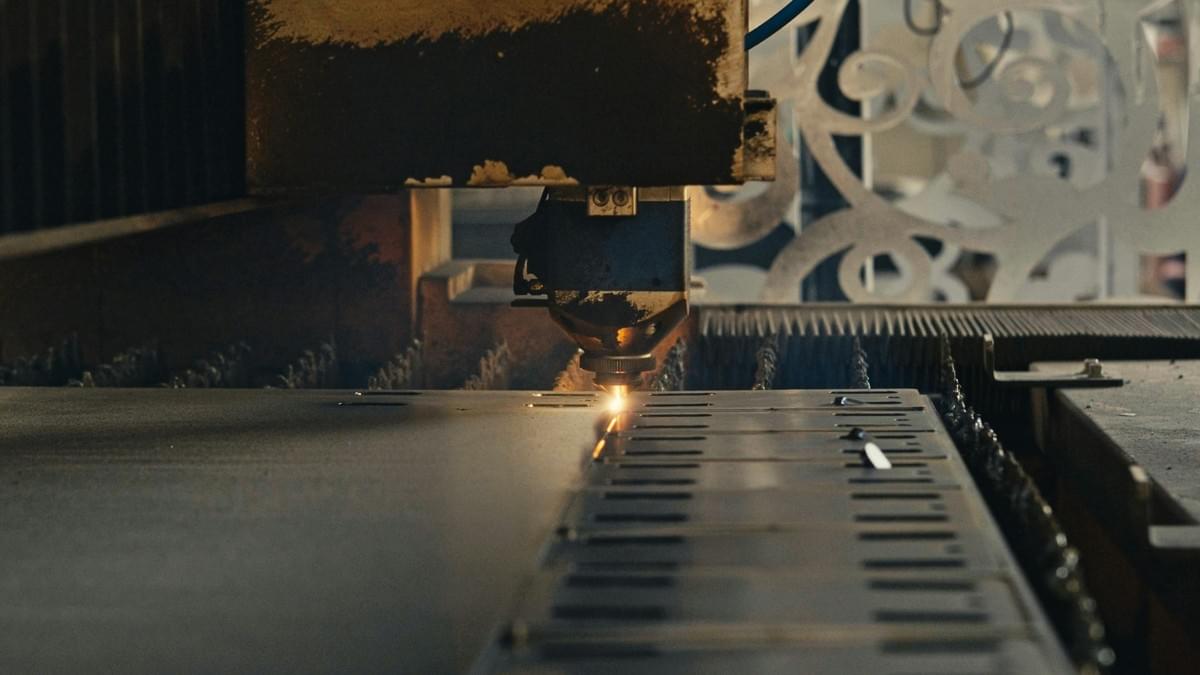

Laser cutting technology has revolutionized the manufacturing landscape, offering precise and efficient solutions for a variety of applications. By harnessing the power of focused laser beams, these machines can slice through materials with incredible accuracy, making them a favored choice among industries. Understanding how this technology works and its benefits can help businesses make informed decisions regarding their laser machine cost.

How Laser Cutting Works

At its core, laser cutting involves directing a high-powered laser beam onto a material's surface to melt or vaporize it, resulting in clean and accurate cuts. The process typically employs either CO2 or fiber lasers, which are chosen based on the type of material being cut and the desired precision. As the laser moves along predetermined paths controlled by computer software, it creates intricate designs that would be challenging to achieve with traditional cutting methods.

This technology relies on advanced optics and motion control systems to maintain accuracy while ensuring rapid processing speeds. The result is not only a reduction in waste but also an increase in productivity—two critical factors for any business considering industrial laser cutters. With such efficiency at play, understanding how these machines function can significantly influence decisions regarding investment and overall laser machine cost.

Advantages of Using Laser Cutters

One of the standout advantages of using laser cutters lies in their unmatched precision and versatility across various materials like metals, plastics, wood, and more. Unlike conventional cutting tools that may leave rough edges or require additional finishing processes, laser cutting produces smooth edges with minimal kerf width—saving both time and resources. Moreover, these machines are capable of executing complex designs that would otherwise be impossible or prohibitively expensive with traditional methods.

Another key benefit is the reduced operational footprint; many modern Laser Cutting Machines are compact yet powerful enough for industrial applications without requiring extensive floor space. This makes them an attractive option for businesses looking to optimize their production lines while keeping an eye on overall costs associated with equipment purchase and maintenance. Ultimately, investing in high-quality industrial laser cutters translates into long-term savings by minimizing material waste and labor costs.

Applications Across Various Industries

The versatility of laser cutting technology has led to its adoption across numerous sectors including automotive, aerospace, electronics, textiles, and even medical device manufacturing. For instance, in the automotive industry, manufacturers utilize these machines for precise component fabrication that meets stringent safety standards without compromising speed or quality. Similarly, aerospace companies rely on lasers for lightweight structural components that enhance fuel efficiency while maintaining performance integrity.

In addition to heavy industries, creative sectors like fashion design leverage laser cutters for intricate fabric patterns that elevate product offerings without sacrificing production efficiency. Furthermore, medical device manufacturers benefit from precise cuts that ensure product reliability while adhering to strict regulatory requirements—showcasing just how integral this technology has become across various fields. As industries continue to evolve toward automation and precision engineering solutions like industrial laser cutters gain traction; understanding their applications can further clarify considerations around initial investments versus long-term benefits.

Price Ranges for Laser Cutting Machines

When it comes to laser cutting machines, understanding the price ranges is crucial for anyone looking to invest in this technology. The costs can vary significantly based on the type of machine, its capabilities, and intended applications. This section will break down the different categories of laser cutting machines to help potential buyers make informed decisions.

Entry-Level Laser Cutting Machines

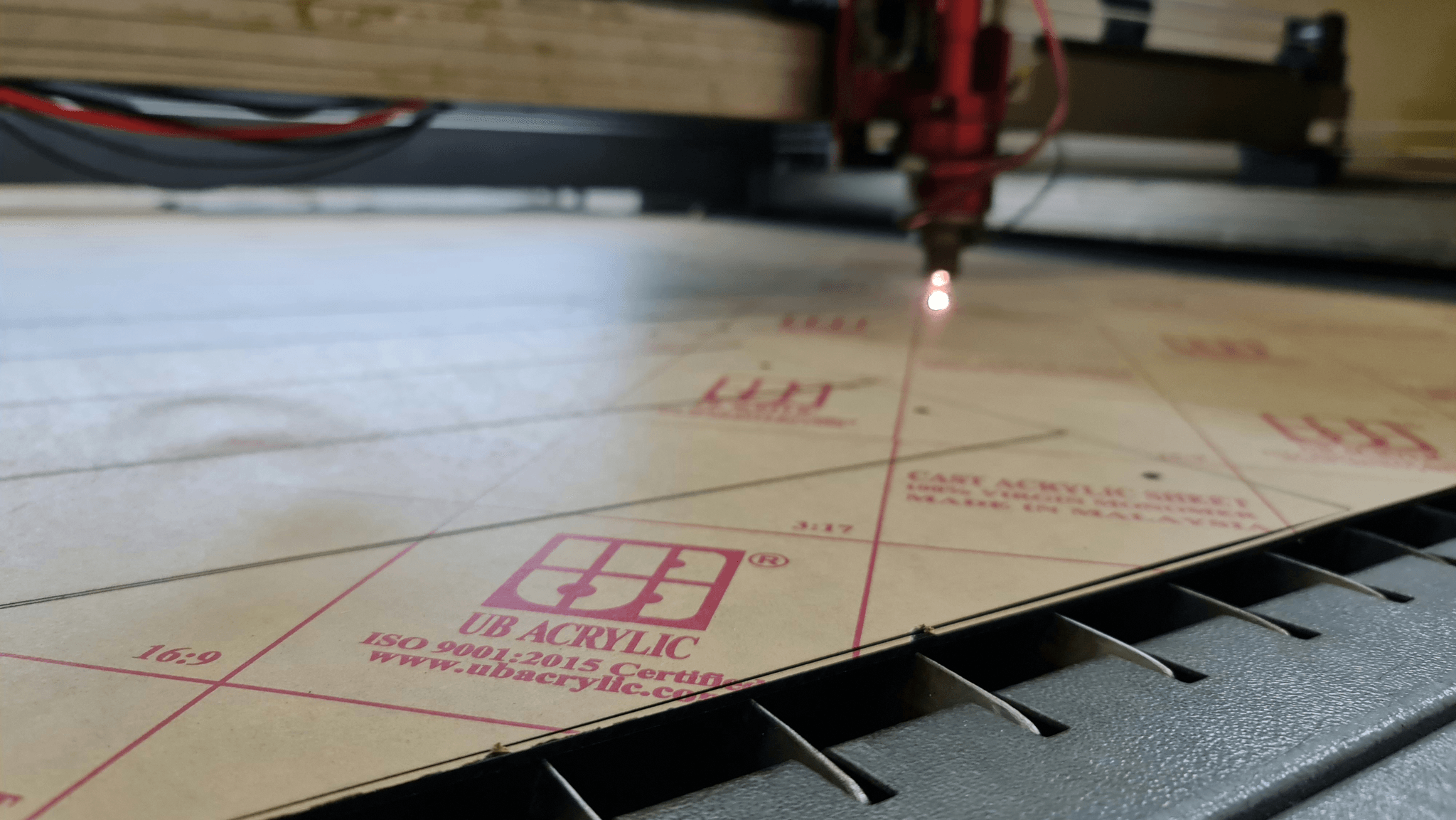

Entry-level laser cutting machines are designed for hobbyists, small businesses, or educational institutions seeking an affordable introduction to laser technology. Typically priced between $2,000 and $10,000, these machines offer basic functionalities suitable for light materials like wood, acrylics, and some metals. While they may lack the power and speed of higher-end models, their lower laser machine cost makes them accessible for those just starting out in the world of laser cutting.

These entry-level models usually come with a smaller bed size and lower wattage lasers but still deliver impressive results for simple projects. Users can expect features such as user-friendly software and compatibility with various design formats, which makes operation straightforward even for beginners. However, it's important to note that while they provide a great entry point into laser cutting technology, they may not be suitable for high-volume production or complex applications.

Mid-Range Industrial Laser Cutters

Mid-range industrial laser cutters fall within the price range of $10,000 to $50,000 and are tailored for small to medium-sized businesses looking to enhance their production capabilities without breaking the bank. These machines often boast increased power levels (typically between 30W to 150W) and larger bed sizes compared to entry-level options. This enhanced performance allows users to cut through thicker materials like stainless steel or aluminum with greater ease.

Investing in a mid-range industrial laser cutter means gaining access to advanced features such as improved cooling systems and faster processing speeds that can significantly boost productivity. Additionally, these machines often come equipped with better software integration options that streamline workflows from design conception through final production stages. For businesses aiming for growth while keeping an eye on budget constraints, these cutters present a balanced solution between cost-efficiency and performance.

High-End Professional Laser Systems

High-end professional laser systems represent the pinnacle of laser machine cost considerations—ranging from $50,000 up to several hundred thousand dollars—these machines are designed for large-scale manufacturing operations requiring precision cuts at high speeds across various materials including metals and composites. These systems typically feature powerful lasers (upwards of 200W), extensive automation capabilities, and larger work areas suited for complex projects.

The investment in high-end industrial laser cutters not only improves efficiency but also enhances accuracy—crucial factors when dealing with intricate designs or high-stakes production runs where quality cannot be compromised. Moreover, many top-tier manufacturers offer customizable solutions tailored specifically to industry needs which can further justify their steep price tags by delivering exceptional value over time through reduced operational costs per unit produced. Ultimately, choosing this category represents a commitment not just towards advanced technology but also towards sustained business growth.

Factors Affecting Laser Machine Cost

When it comes to understanding laser machine cost, several key factors come into play. The price of a Laser Cutting Machine can vary significantly based on specifications, brand reputation, and additional features that enhance performance. By breaking down these elements, potential buyers can make informed decisions that align with their operational needs and budget.

Power and Performance Specifications

The power and performance specifications of a laser cutting machine are among the most significant determinants of its cost. Generally, higher wattage machines tend to command higher prices due to their ability to cut through thicker materials more efficiently. Additionally, advanced technologies such as fiber optics or CO2 lasers contribute not only to the initial laser machine cost but also to long-term productivity gains in industrial settings.

Investing in a high-performance Industrial Laser Cutter may seem steep initially, yet it often pays off through increased operational efficiency and reduced production time. Buyers should consider their specific cutting requirements—whether they need precision for intricate designs or the power for bulk production—to ensure they select a machine that provides optimal value for its price tag. Ultimately, understanding these specifications helps businesses find the right balance between capability and cost.

Brand Reputation and Reliability

Brand reputation plays a crucial role in determining laser machine cost; established brands often charge more due to their proven reliability and customer service support. Investing in a reputable brand usually means you're getting a product that has been tested rigorously over time, which could save you from costly repairs or downtime later on. While lesser-known brands may offer lower prices on their Laser Cutting Machines, potential buyers should weigh the risks against possible savings.

Moreover, reliable manufacturers typically provide comprehensive warranties and after-sales support—additional costs that might not be apparent upfront but are essential for long-term satisfaction with your purchase. When considering industrial laser cutters, it's wise to research customer reviews and testimonials; this can reveal insights into how well machines perform over time and how responsive companies are when issues arise. In short, opting for a reputable brand could translate into greater peace of mind regarding your investment.

Additional Features and Technology

The inclusion of additional features significantly impacts the overall laser machine cost; advanced technology often comes at a premium but can greatly enhance functionality. Features such as automated focus adjustment, integrated software solutions for design optimization, or advanced cooling systems can improve both usability and precision in cutting tasks. While these enhancements increase initial costs for Laser Cutting Machines, they can lead to improved productivity levels down the line.

Furthermore, technology like smart sensors or IoT connectivity allows for real-time monitoring of performance metrics—an attractive proposition for industries looking to streamline operations further. Although you might pay more upfront for these added features in an industrial laser cutter compared to basic models, they often result in lower operational costs over time by reducing waste and increasing throughput efficiency. Thus, evaluating these additional features is crucial when determining whether the investment aligns with your business goals.

Cost of Maintenance and Operation

When considering the overall investment in a Laser Cutting Machine, it's crucial to factor in the costs associated with maintenance and operation. Understanding these costs can significantly impact your budgeting and financial planning, especially for businesses relying on Industrial Laser Cutters for production. The initial purchase price is just the tip of the iceberg; ongoing expenses can add up quickly if not carefully managed.

Routine Maintenance Expenses

Routine maintenance is essential to keep your Laser Cutting Machine running smoothly and efficiently. Depending on the type of machine you own, routine maintenance expenses may include replacing worn-out parts, cleaning lenses, and calibrating settings to ensure precision cutting. Regular upkeep not only prolongs the lifespan of your equipment but also helps maintain optimal performance, ultimately saving you money on repairs in the long run.

Additionally, some manufacturers offer service packages that bundle routine maintenance into a single cost-effective solution; however, this can vary widely based on brand reputation and reliability. Investing in quality service can mitigate unexpected breakdowns that could disrupt production schedules or incur costly repairs later on. So while it might seem like an extra expense upfront, budgeting for routine maintenance is a smart move for anyone serious about managing laser machine costs effectively.

Operating Costs: Energy and Materials

Operating costs are another critical aspect when evaluating laser machine cost over time. The energy consumption of Industrial Laser Cutters can vary significantly based on their power specifications; higher wattage machines typically consume more electricity but also offer faster cutting speeds and capabilities for thicker materials. Understanding these energy requirements will help you estimate monthly utility bills accurately.

Materials used during operation—such as gases for cutting or specific substrates—also contribute to overall operating expenses. It's important to consider not only the cost of raw materials but also how efficiently your Laser Cutting Machine utilizes them; machines with advanced technology often minimize waste while maximizing output efficiency. Therefore, conducting a thorough analysis of both energy consumption and material usage will provide a clearer picture of ongoing operational costs associated with your laser cutter.

Long-Term Cost Considerations

When assessing long-term cost considerations related to your Laser Cutting Machine investment, it's essential to take into account depreciation rates as well as potential technological advancements that could affect future operations. Over time, older models may require more frequent repairs or become less efficient compared to newer machines equipped with cutting-edge features—this is particularly relevant in industries where precision and speed are paramount.

Moreover, calculating return on investment (ROI) involves looking beyond immediate savings; consider how improved efficiency from regular upgrades or replacements can lead to increased productivity and profitability over time. By factoring these elements into your overall financial strategy, you'll be better prepared to make informed decisions about purchasing new Industrial Laser Cutters or upgrading existing ones as technology evolves.

In summary, while understanding laser machine costs primarily focuses on initial purchase prices, it’s equally important to account for ongoing maintenance and operational expenses that contribute significantly to total ownership costs over time.

Comparing Costs from Different Manufacturers

When it comes to investing in a laser cutting machine, understanding the landscape of manufacturers can significantly impact your decision. The market is filled with various players, each offering a range of products at different price points. By comparing costs and features from these manufacturers, you can better gauge what fits your budget while meeting your operational needs.

Review of Major Players in the Market

In the realm of laser cutting machines, several major manufacturers dominate the scene. Companies like Trumpf, Amada, and Bystronic are known for their high-quality industrial laser cutters that cater to both small businesses and large enterprises alike. Each brand brings unique strengths to the table—Trumpf excels in advanced technology and innovation, while Amada offers robust customer support and customization options.

However, it’s important to note that with high-quality machinery often comes a higher laser machine cost. While these brands might be appealing for their reputation and capabilities, they may not always align with every budget or operational requirement. Therefore, doing thorough research on each manufacturer’s offerings is essential for making an informed choice.

How Kiant Machinery Stands Out

Kiant Machinery has carved out a niche in this competitive market by offering reliable yet affordable laser cutting solutions tailored for various industries. Their laser cutting machines are priced competitively without sacrificing quality or performance—a win-win for those mindful of their budgets! Kiant's focus on user-friendly designs makes their machines accessible even for those new to laser technology.

Moreover, Kiant Machinery places a strong emphasis on innovation by integrating advanced features into their models that enhance productivity and efficiency. This means you get more bang for your buck when considering overall value rather than just initial laser machine cost. As businesses increasingly seek cost-effective solutions without compromising quality, Kiant stands out as a compelling option worth considering.

Importance of After-Sales Support

After-sales support is often an overlooked aspect when comparing costs from different manufacturers but can be crucial in determining long-term satisfaction with your purchase. A company that provides robust after-sales service can save you time and money down the line by ensuring any issues are resolved quickly and efficiently—this directly impacts operational costs associated with downtime or repairs on industrial laser cutters.

When evaluating potential vendors, consider factors such as warranty duration, availability of spare parts, and technical support options offered by each manufacturer. A lower initial investment may become costly if after-sales support is lacking; thus, it’s wise to weigh this against the overall laser machine cost before finalizing any decisions. In essence, investing time into understanding after-sales services could lead to smarter financial choices down the road.

Conclusion

In the world of manufacturing and fabrication, understanding laser machine cost is crucial for making informed decisions. With various types of Laser Cutting Machines available, each with its own price point and features, it’s essential to evaluate not only the initial purchase price but also the long-term value they provide. A well-researched choice can lead to enhanced productivity and efficiency in your operations.

Making Informed Decisions on Purchases

When considering a Laser Cutting Machine, it's vital to assess your specific needs and how different models align with them. Factors such as power output, cutting speed, and material compatibility should guide your decision-making process. Additionally, don’t overlook the importance of brand reputation; investing in reliable Industrial Laser Cutters can save you from costly repairs down the line.

Budgeting for Laser Cutting Operations

Budgeting for laser cutting operations involves more than just the upfront laser machine cost; it requires a comprehensive view of ongoing expenses too. Consider factors like energy consumption, maintenance costs, and material expenses when planning your budget. By accounting for these elements, you can ensure that your investment in a Laser Cutting Machine translates into sustained profitability over time.

Understanding Value Beyond Initial Costs

The true value of a Laser Cutting Machine often extends beyond its initial cost; it encompasses operational efficiency and output quality as well. High-quality Industrial Laser Cutters may come with a higher price tag but can significantly reduce waste and improve precision in production processes. Ultimately, evaluating the total cost of ownership will provide better insights into how these machines contribute to your business's success.