Introduction

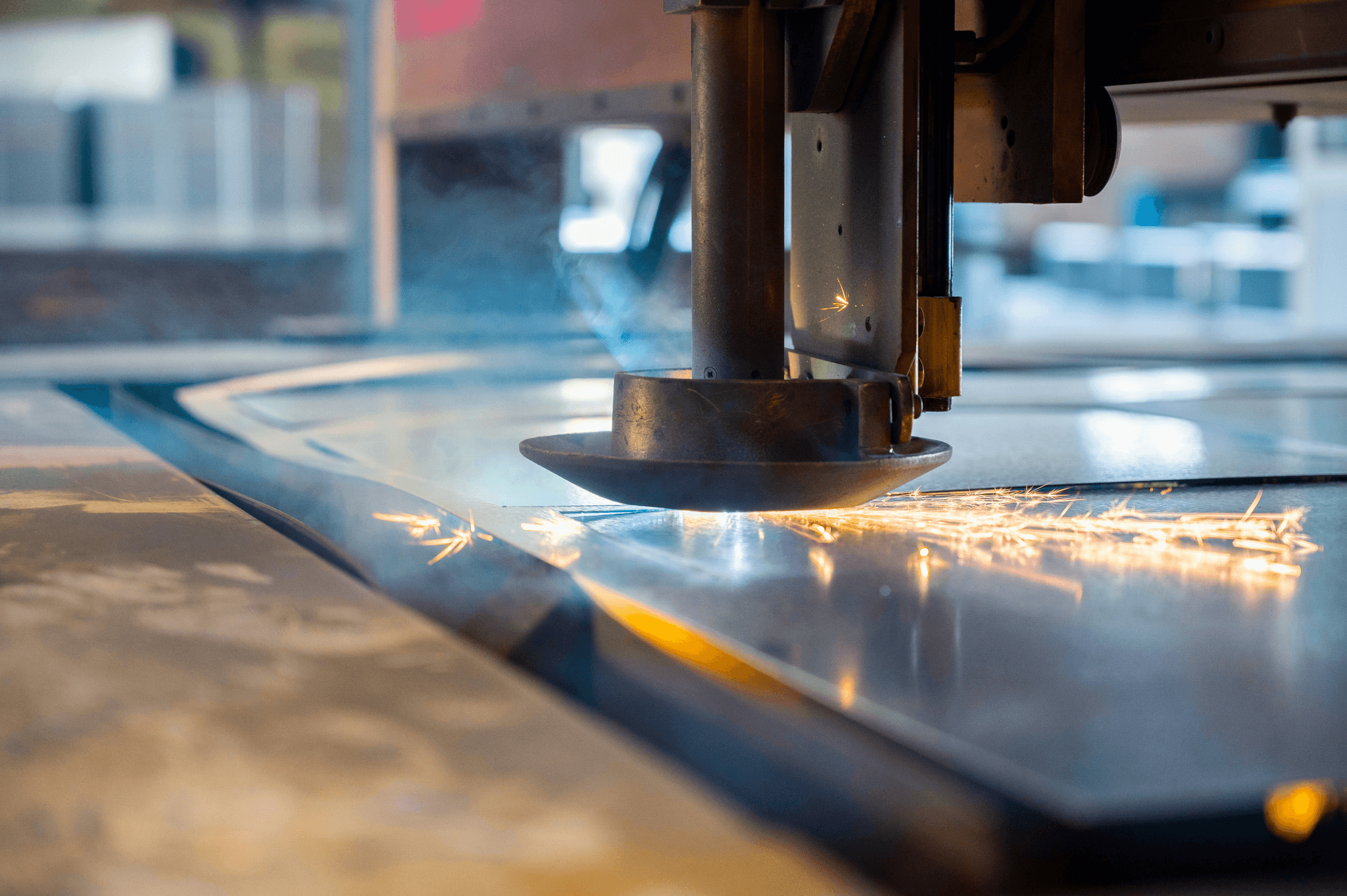

In today’s fast-paced manufacturing landscape, the role of steel pipe laser cutting has become increasingly vital. This advanced technology not only streamlines production but also enhances the quality and precision of metal components. With a metal cutting machine laser, businesses can achieve superior results that traditional methods simply can't match.

Discover the Benefits of Steel Pipe Laser Cutting

Steel pipe laser cutting offers a plethora of benefits that make it an attractive option for various industries. One of the most significant advantages is its precision; a laser cutter can create intricate designs with minimal material waste, ensuring that every cut is exact. Additionally, this method allows for faster turnaround times compared to conventional techniques, boosting productivity and efficiency in any project.

Why Metal Cutting Laser Options Matter

Different projects may require specific capabilities from a metal machine cutter, whether it's dealing with varying thicknesses or complex geometries. By understanding these options, businesses can select the right laser cutting machine that aligns with their unique needs and maximizes their operational potential.

The Evolution of Laser Cutting Technology

The evolution of laser cutting technology has been nothing short of remarkable over recent decades. From bulky machines that operated slowly to today's sleek and efficient models designed for steel tube laser cutting, advancements have transformed how manufacturers approach metalworking tasks. As innovations continue to emerge in this field, we are witnessing an exciting future where even greater precision and automation will redefine what's possible in metal fabrication.

Advantages of Steel Pipe Laser Cutting

When it comes to steel pipe laser cutting, the advantages are hard to ignore. This modern approach to metal cutting not only enhances precision but also brings speed and versatility to the table. Let’s dive into why this technology is revolutionizing the way we handle metal fabrication.

Precision and Accuracy in Metal Cutting

One of the standout features of a laser cutter is its unparalleled precision in metal cutting. Unlike traditional methods that can leave room for human error, a laser cutting machine operates with incredible accuracy, ensuring that every cut is exact and clean. This level of precision is crucial for projects requiring tight tolerances, making steel tube laser cutting an ideal choice for industries where detail matters.

Moreover, the ability to program intricate designs means that complex shapes can be achieved without compromising on quality. Whether you’re crafting components for machinery or creating artistic pieces, a metal machine cutter guarantees uniformity across all cuts. In essence, when you invest in steel pipe laser cutting technology, you’re investing in superior craftsmanship.

Speed and Efficiency Over Traditional Methods

Time is money in any industry, and that's where the speed of a metal cutting machine laser truly shines. Compared to traditional methods like plasma or oxy-fuel cutting, laser cutting drastically reduces processing time while maintaining high-quality results. A well-timed cut can mean quicker project turnaround times and increased productivity—something every business strives for.

Additionally, this efficiency extends beyond just speed; it also involves minimal material waste due to precise cuts that require less rework or scrap material. With a steel pipe laser cutting setup, businesses can optimize their operations while saving on costs associated with excess materials and labor-intensive processes. In short, switching to a laser cutter can transform your workflow into a leaner operation.

Versatility for Various Project Needs

The versatility of a metal cutting laser cutter makes it suitable for an array of applications across different sectors. From industrial manufacturing to artistic endeavors, these machines adapt seamlessly to various project requirements—whether it's thick steel pipes or delicate plates needing intricate designs. The flexibility offered by modern laser technologies means that one machine can handle multiple tasks without sacrificing quality.

Furthermore, advancements in technology allow users to easily switch between different materials such as aluminum or stainless steel without extensive setup changes. This adaptability empowers businesses to take on diverse projects without investing heavily in multiple types of equipment—a significant advantage in today’s fast-paced market environment. Ultimately, choosing steel pipe laser cutting opens up new avenues for creativity and efficiency alike.

Applications of Laser Cutting Machines

Laser cutting machines have revolutionized various industries, offering unparalleled precision and efficiency. From manufacturing to creative arts, the versatility of a laser cutter makes it an invaluable tool for diverse applications. In this section, we will explore how steel pipe laser cutting and other metal cutting laser technologies are transforming different sectors.

Industrial Uses in Construction and Manufacturing

In the construction and manufacturing sectors, steel pipe laser cutting is a game-changer. The accuracy of a metal machine cutter allows for intricate designs and precise cuts that traditional methods simply can't match. Whether it's creating structural components or fabricating parts for machinery, a laser cutting machine streamlines processes while enhancing quality.

Manufacturers are increasingly turning to metal cutting machines because they can handle various materials beyond just steel pipes. The adaptability of these machines means that businesses can optimize their production lines without investing in multiple types of equipment. This not only saves time but also reduces costs associated with material waste and labor.

Moreover, the speed at which a metal cutting laser cutter operates means that projects can be completed faster than ever before. This efficiency is crucial in industries where deadlines are tight, allowing companies to meet customer demands without sacrificing quality or precision.

Custom Metal Fabrication Projects

Custom metal fabrication has seen significant advancements thanks to the introduction of advanced laser cutting technology. With the ability to create complex shapes and detailed designs, steel tube laser cutting opens new doors for artists and fabricators alike. Whether crafting bespoke furniture or intricate signage, the flexibility offered by a laser cutter allows for unique creations tailored to specific needs.

The precision provided by these machines ensures that every piece fits perfectly within its intended space, eliminating costly errors often associated with manual fabrication methods. Additionally, custom projects benefit from reduced lead times since a metal machine cutter can quickly produce prototypes or final products directly from digital files.

As businesses strive for differentiation in their offerings, custom fabrication through metal cutting lasers becomes essential for standing out in competitive markets. By leveraging these technologies, companies can push creative boundaries while efficiently delivering high-quality products that meet client specifications.

Innovations in Art and Design Using Laser Cutters

The world of art has been significantly enhanced by innovations in laser technology; artists now utilize steel pipe laser cutting techniques to bring their visions to life with remarkable detail and finesse. From sculptures to decorative panels, the capabilities of a metal cutting machine are limited only by imagination itself. Artists appreciate how easily they can manipulate materials like wood or acrylic alongside metals using advanced laser cutters.

Moreover, collaborative projects between designers and engineers have led to groundbreaking works that blend functionality with aesthetics—think architectural installations or interactive exhibits! The precision achieved through steel tube laser cutting allows creators to experiment more boldly with form while ensuring structural integrity remains intact.

In addition to traditional art forms, modern designers use these tools for creating stunning visual displays at events or exhibitions—showcasing how versatile a simple beam of light can be when wielded effectively! As innovations continue to emerge within this field, we anticipate even more exciting applications that will push both artistic boundaries and technological capabilities further than ever before.

Choosing the Right Laser Cutting Machine

When it comes to selecting the right laser cutting machine, there’s more to consider than just price. The world of steel pipe laser cutting is vast and filled with options tailored for different needs and applications. Whether you're a small workshop or a large manufacturing facility, understanding what features matter most can make all the difference in your metal cutting efficiency.

Factors to Consider When Selecting Equipment

First and foremost, think about the material you'll be working with. If your primary focus is on steel pipe laser cutting, ensure that the machine you choose can handle various thicknesses and types of steel effectively. Additionally, consider the power output of the metal cutting laser cutter; higher wattage typically translates to faster cuts and cleaner edges.

Next up is precision—an essential factor in any metal machine cutter. Look for specifications that highlight accuracy levels; this will help ensure your projects meet stringent quality standards. Finally, don’t overlook software compatibility; a user-friendly interface can significantly streamline operations and enhance productivity when using a laser cutter.

Lastly, evaluate support services offered by manufacturers. A reliable metal cutting machine laser supplier should provide adequate training and ongoing support to help you maximize your investment in steel tube laser cutting technology. Remember, choosing a machine isn’t just about today’s needs but also about future growth potential.

Kiant Machinery's Advanced Solutions

Kiant Machinery stands out as a leader in innovative solutions for those seeking top-notch laser cutting machines. Their range of products caters specifically to industries focused on precision metal work, including advanced models designed for steel pipe laser cutting applications. Each machine boasts state-of-the-art features that enhance speed without sacrificing accuracy—a winning combination for any project.

One notable offering from Kiant Machinery is their high-performance metal cutting machine laser series, which incorporates intelligent technology for improved efficiency. These machines are equipped with advanced sensors that optimize performance based on material type and thickness—making them incredibly versatile tools for various tasks beyond basic cuts. With Kiant's commitment to quality and innovation, you can rest assured knowing you're investing in machinery built to last.

Moreover, Kiant Machinery provides comprehensive training resources that enable users to get up-to-speed quickly with their new equipment—ensuring minimal downtime during transitions from older methods of metal processing like traditional saws or plasma cutters. This level of support sets them apart from competitors who may not offer such extensive assistance.

Comparing Costs and Long-Term Value

When comparing costs associated with different laser cutters, it’s crucial not only to look at upfront prices but also at long-term value propositions they offer over time—especially regarding maintenance expenses related to steel tube laser cutting machines versus traditional options such as band saws or oxy-fuel systems! While an initial investment might seem higher for advanced models from brands like Kiant Machinery initially may seem daunting; consider how much money could be saved through reduced labor costs due to faster processing times!

Additionally, factor in energy consumption rates when evaluating overall operational costs associated with using these powerful tools regularly—it’s no secret that modern lasers tend toward greater energy efficiency compared with older technologies! This translates into lower utility bills while still delivering exceptional performance across diverse projects involving intricate designs requiring precise cuts consistently achieved by utilizing today’s state-of-the-art technology available within this industry niche!

In conclusion: investing wisely means looking beyond mere purchase price tags attached directly onto equipment listings online—think strategically about how chosen solutions will impact overall productivity levels achieved throughout daily operations moving forward into tomorrow's competitive landscape!

Maintenance Tips for Laser Cutting Machines

Maintaining your laser cutting machine is essential for ensuring optimal performance and longevity. A well-maintained metal cutting machine laser not only enhances precision in steel pipe laser cutting but also minimizes downtime caused by unexpected malfunctions. Regular maintenance can save you money in the long run by preventing costly repairs and extending the lifespan of your equipment.

Keeping Your Metal Cutting Machine in Top Shape

To keep your metal cutting machine laser operating at peak efficiency, regular cleaning is crucial. Dust and debris can accumulate on the optics and rails, affecting the quality of cuts made by a laser cutter. Additionally, checking alignment and calibration regularly ensures that your steel tube laser cutting remains precise, allowing you to tackle various projects with confidence.

Another important aspect of maintenance is monitoring consumables like lenses and nozzles. Replacing these components as needed will ensure that your metal machine cutter delivers optimal performance during steel pipe laser cutting tasks. Lastly, keeping an eye on coolant levels helps prevent overheating, which can lead to significant damage over time.

Troubleshooting Common Issues

Even the best-maintained laser cutting machines can encounter issues from time to time. One common problem is inconsistent cut quality, which could stem from a dirty lens or misalignment of the beam path in your metal cutting laser cutter. If you notice this issue, start by inspecting the optics for any residue or damage before recalibrating your equipment.

Another frequent concern is unexpected shutdowns during operation, often caused by overheating or power supply fluctuations. Ensuring proper ventilation around your equipment can help mitigate overheating issues while using a reliable power source will minimize interruptions during critical steel tube laser cutting projects. If problems persist despite troubleshooting efforts, consulting with professionals may provide additional insights.

Best Practices for Longevity of Equipment

To ensure that your metal cutting machine lasts as long as possible, adopting best practices is key. First off, develop a routine maintenance schedule that includes regular checks on all moving parts and electrical connections to identify wear before it becomes problematic. This proactive approach allows you to address potential issues early on rather than waiting for a breakdown during vital steel pipe laser cutting operations.

Additionally, training staff on proper usage techniques significantly decreases wear and tear on machinery while promoting safe working conditions around the metal machine cutter area. Encourage them to follow manufacturer guidelines closely when operating the equipment; this not only preserves functionality but also enhances safety protocols within your workspace.

Lastly, consider investing in high-quality replacement parts when necessary to maintain performance standards over time—after all, using subpar components could lead to more frequent breakdowns or inferior cut quality from your laser cutter than desired! By following these best practices diligently, you'll ensure that both productivity levels and project outcomes remain high throughout every phase of operation.

Future Trends in Laser Cutting Technology

The landscape of laser cutting technology is evolving rapidly, paving the way for more efficient and innovative solutions in steel pipe laser cutting. With advancements in hardware and software, the capabilities of a laser cutter are expanding, allowing for greater precision and versatility. As industries seek to enhance productivity and reduce waste, staying ahead of these trends is essential for any metalworking operation.

Emerging Innovations in Steel Tube Laser Cutting

Emerging innovations in steel tube laser cutting are transforming how manufacturers approach metal fabrication. New technologies are being developed that enhance the speed and accuracy of a metal cutting machine laser, making it possible to handle complex designs with ease. These advancements not only reduce production times but also minimize material wastage, making steel pipe laser cutting more economical than ever.

One notable innovation is the integration of advanced optics and beam control systems that improve cut quality while reducing energy consumption. Additionally, some manufacturers are exploring fiber lasers which provide higher efficiency and longer lifespans compared to traditional CO2 lasers. This shift towards more sustainable options ensures that businesses can meet their production goals while adhering to environmental standards.

The Impact of Automation on Metal Cutting

Automation is playing a pivotal role in reshaping the future of metal cutting processes, including steel pipe laser cutting applications. By incorporating automated systems into their workflows, companies can significantly increase throughput while minimizing human error associated with manual operations. Automated loading and unloading systems for a laser cutter streamline production lines, allowing operators to focus on other critical tasks.

Moreover, smart technology integration enables real-time monitoring and data analytics within metal cutting machines lasers, enhancing operational efficiency further. This means that businesses can adapt quickly to changing demands without compromising on quality or speed—an essential factor in today’s fast-paced manufacturing environment. As automation continues to advance, we can expect even greater improvements in productivity across various sectors utilizing metal machine cutters.

Sustainability in Laser Cutting Practices

Sustainability has become a driving force behind innovations in laser cutting technology as industries strive to reduce their carbon footprints. Steel pipe laser cutting processes are increasingly being designed with eco-friendly practices at their core; from energy-efficient machines to practices aimed at reducing material waste during production runs. Implementing these sustainable measures not only helps protect the environment but also enhances corporate social responsibility efforts.

Companies are now investing in research aimed at developing biodegradable materials compatible with existing metal cutting machines lasers—creating new avenues for eco-conscious fabrication projects. Furthermore, many manufacturers are adopting closed-loop systems that recycle scrap materials generated during the cutting process back into usable resources for future projects. By prioritizing sustainability within their operations, businesses position themselves as leaders committed to responsible manufacturing practices.

Conclusion

In the world of manufacturing and fabrication, steel pipe laser cutting stands out as a game-changer. The precision and efficiency that a laser cutter brings to metal cutting processes elevate project quality to new heights. As industries evolve, embracing advanced technologies like laser cutting machines is essential for staying competitive and meeting the demands of modern projects.

Elevating Project Quality with Laser Cutting

Steel tube laser cutting offers unmatched accuracy that traditional methods simply can't replicate. This level of precision ensures that each component fits perfectly, reducing waste and minimizing the need for costly rework. By incorporating a metal cutting machine laser into your operations, you not only enhance the quality of your products but also streamline your workflow.

The Role of Technology in Modern Manufacturing

The integration of innovative technologies such as metal cutting lasers has revolutionized manufacturing processes across various sectors. Laser cutting machines are no longer just tools; they are pivotal in driving efficiency and productivity within factories. As companies adopt these advanced solutions, they can respond more quickly to market demands while maintaining high-quality standards.

Partnering with Experts Like Kiant Machinery

When it comes to selecting a reliable metal machine cutter, partnering with experts like Kiant Machinery can make all the difference. Their extensive knowledge in steel pipe laser cutting ensures you choose the right equipment tailored to your specific needs. With their support, you can maximize your investment in a laser cutter while gaining access to ongoing maintenance and expert advice.