Introduction

Light gauge steel framing has become a popular choice in modern construction, offering a versatile and durable alternative to traditional building materials. This innovative method utilizes thin sheets of steel to create strong structural supports, making it an efficient option for building a steel building. With the rise of metal framing techniques, understanding the intricacies of light gauge steel machines and their applications is essential for anyone involved in steel building construction.

Understanding Light Gauge Steel Framing

Light gauge steel framing refers to the use of thin-walled steel sections that are cold-formed into various shapes, providing strength while minimizing weight. This type of construction is particularly significant due to its ability to resist environmental factors such as wind and seismic activity, making it a reliable choice for diverse applications. The process involves using advanced technology like light gauge steel machines that efficiently produce components for constructing stud wall steel frames.

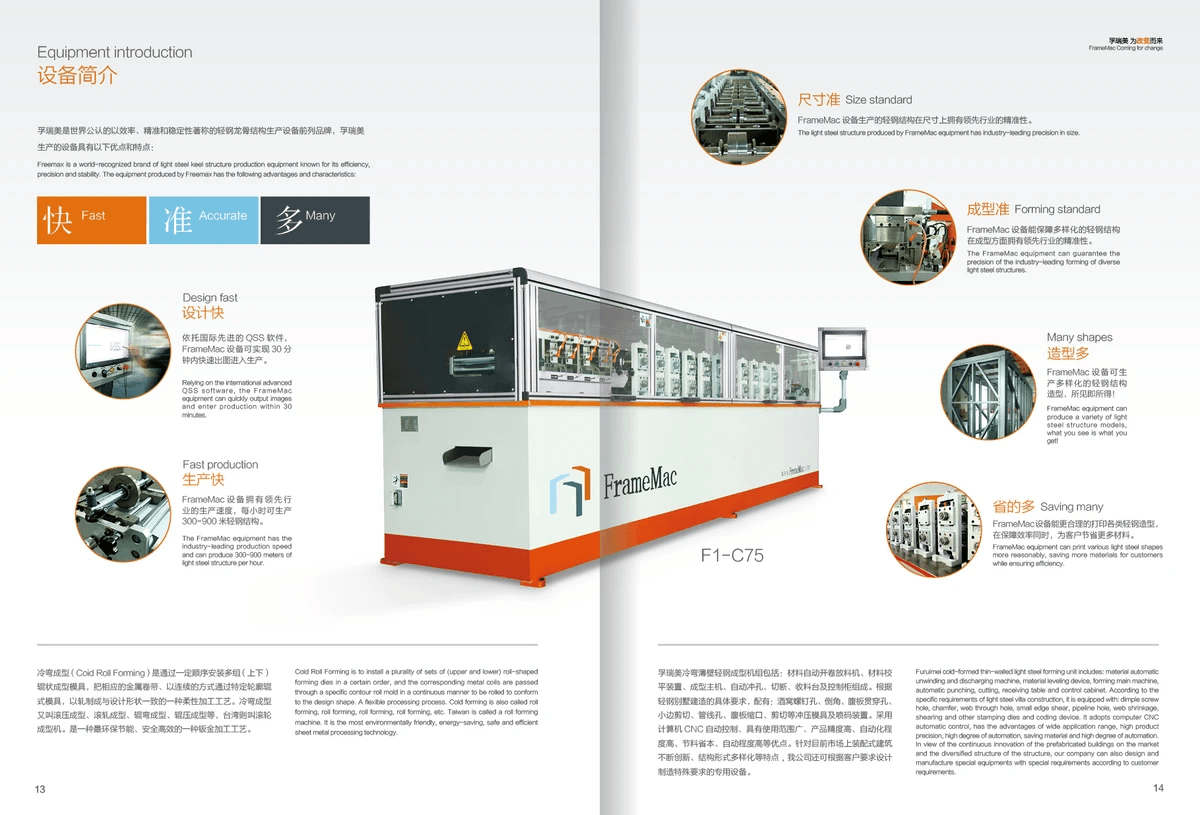

The Role of Roll Forming Machines

At the heart of light gauge steel framing is the roll forming machine, which transforms flat sheets of steel coil into precisely shaped components needed for metal framing. These machines operate through a series of rollers that gradually bend and shape the material, ensuring consistency and accuracy in production. Choosing the right roll forming machine can greatly influence the efficiency and quality of building a steel building, as different machines cater to varying specifications and requirements.

Benefits of Steel in Construction

The advantages of using steel in construction are numerous, especially when it comes to durability and cost-effectiveness. Steel's inherent strength allows for lighter structures without compromising stability, making it ideal for modern designs that prioritize open spaces and flexibility. Furthermore, utilizing light gauge steel machines not only streamlines production but also contributes significantly to reducing overall project costs in metal framing endeavors.

What is Light Gauge Steel Framing?

Light gauge steel framing is revolutionizing the construction landscape, providing a modern alternative to traditional building materials. This innovative approach uses thin sheets of steel that are cold-formed into structural shapes, offering unique benefits in terms of strength and versatility. As more builders embrace this method, understanding its significance becomes crucial for anyone involved in steel building construction.

Definition and Significance

At its core, light gauge steel framing refers to the use of steel studs and tracks to create a skeletal structure for buildings. These components are typically lighter than traditional wooden framing but maintain exceptional strength and durability, making them ideal for various applications. The significance of using light gauge steel machines lies in their ability to streamline the construction process while ensuring robust structural integrity.

Applications in Steel Building Construction

The applications of light gauge steel framing are vast and varied, extending beyond just residential buildings to commercial structures and industrial facilities. This method is particularly popular in multi-story buildings where weight considerations are paramount; using a stud wall steel frame allows for taller constructions without compromising stability. Furthermore, with the rise of prefabricated components made from steel coil, builders can speed up project timelines while maintaining high-quality standards.

Comparison with Traditional Materials

When comparing light gauge steel framing to traditional materials like wood or concrete, several advantages emerge that make it an attractive option for builders today. For starters, metal framing is inherently resistant to pests such as termites and does not warp or shrink over time like wood might do under varying environmental conditions. Additionally, light gauge steel machines enable precise manufacturing processes that result in consistent quality across all components—something that can be challenging with natural materials like lumber.

How Roll Forming Machines Work

Roll forming machines are the unsung heroes of steel building construction, expertly crafting light gauge steel components that form the backbone of modern structures. These machines take flat steel coils and transform them into precisely shaped profiles, which are essential for metal framing applications like stud wall steel frames. Understanding how these machines operate is crucial for anyone involved in building a steel building.

The Mechanism Explained

At its core, a roll forming machine operates on the principle of continuous bending. The process begins with feeding a flat steel coil into the machine, where it is gradually shaped through a series of rollers that incrementally bend it into the desired profile. This method not only ensures high efficiency but also produces consistent quality in every piece, making it ideal for light gauge steel machines used in construction.

The rollers are designed to apply specific amounts of pressure at precise angles, allowing for various shapes to be formed without compromising the integrity of the material. As each section passes through the rollers, it emerges as a finished product ready for assembly in metal framing projects. This streamlined approach significantly reduces waste and improves production timelines—key factors when building a steel building.

Types of Roll Forming Machines

There are several types of roll forming machines tailored to different applications within steel building construction. The most common types include conventional roll formers, which are versatile and can create a wide range of shapes; and precision roll formers that focus on producing highly accurate profiles with tight tolerances—perfect for critical components like those used in stud wall steel frames.

Additionally, there are specialized roll forming machines designed specifically for light gauge steel framing or other niche applications within metal framing projects. Each type has its own set of features and capabilities, so understanding these differences can help contractors choose the right equipment based on their specific needs and production goals.

Choosing the Right Machine

Selecting the appropriate roll forming machine is vital for maximizing efficiency and output during construction projects involving light gauge steel machinery. Factors to consider include production volume requirements, material thickness compatibility, and flexibility in creating various profiles needed for different aspects of your project—like those required in stud wall installations.

It's also essential to evaluate technological advancements offered by manufacturers; modern machines often come equipped with automation features that enhance precision while reducing labor costs during metal framing operations. Investing time upfront to choose wisely will pay off later when you’re knee-deep in building a steel building where every detail counts.

Advantages of Using Light Gauge Steel Machines

When it comes to modern construction, light gauge steel machines are revolutionizing the way we think about building a steel building. These machines offer a plethora of advantages that make them an attractive option for contractors and builders alike. From enhanced durability to cost-effectiveness, the benefits of using light gauge steel machines are hard to ignore.

Enhanced Durability and Strength

One of the most compelling reasons to opt for light gauge steel in metal framing is its enhanced durability and strength. Unlike traditional materials that may warp or degrade over time, steel retains its structural integrity even under harsh conditions. This means that when you’re building a steel building, you can trust that the framework will stand strong against environmental challenges like wind, moisture, and pests.

Light gauge steel machines play a pivotal role in this process by producing high-quality components with precise specifications. The result? A stud wall steel frame that not only meets but often exceeds industry standards for strength and resilience. Ultimately, this durability translates into lower maintenance costs over the lifespan of your structure.

Lightweight Yet Strong Structural Support

Another significant advantage of using light gauge steel is its lightweight nature combined with remarkable strength. Unlike traditional wooden frames which can be cumbersome and heavy, light gauge steel machines create components that are easy to handle without sacrificing structural support. This lightweight characteristic makes transportation and installation much more efficient during the construction phase.

Moreover, because the material is so strong relative to its weight, builders can design larger spans without needing additional support beams or columns—a game changer in many architectural applications! This efficiency not only streamlines the construction process but also opens up creative possibilities for designing innovative spaces within your new steel building.

Cost-Effectiveness in Steel Building Construction

When considering options for metal framing in your next project, cost-effectiveness is always at the forefront of decision-making processes—and rightfully so! Light gauge steel machines offer a budget-friendly alternative compared to traditional materials like wood or concrete while delivering superior performance and longevity. With reduced labor costs due to easier handling and quicker assembly times, investing in these machines pays off.

Additionally, because they produce less waste during fabrication compared to other methods used in constructing stud wall steel frames, there’s less financial loss associated with discarded materials. Plus, when you factor in lower maintenance expenses over time due to their durability, it’s clear why many builders are making the switch toward light gauge steel solutions for their projects.

The Process of Metal Framing

Metal framing is a crucial step in the construction of steel buildings, providing the structural backbone that supports everything from walls to roofs. This process involves several stages, each requiring attention to detail and precision. Understanding the workflow not only enhances efficiency but also ensures that the final product meets all safety and design standards.

Step-by-Step Overview

The process of metal framing begins with planning and design, where architects and engineers lay out specifications for the steel building construction. Once plans are finalized, it’s time to prepare materials—this includes selecting appropriate light gauge steel machines for cutting and shaping steel coils into usable components. Following material preparation, assembly takes place on-site, where individual pieces are connected to form stud wall steel frames that will support various building elements.

After assembling the frames, inspections are carried out to ensure structural integrity before moving on to insulation and drywall installation. This systematic approach not only streamlines the construction process but also maximizes the benefits of using metal framing in building a steel building. Each step is critical; skipping any could lead to complications down the line.

Preparing Steel Coils for Framing

Preparing steel coils is an essential part of metal framing that lays the foundation for effective construction practices. Initially, coils are inspected for quality; any defects can compromise strength during assembly in a steel building structure. Once confirmed as suitable, these coils are fed into light gauge steel machines which cut them into specific lengths based on project requirements.

After cutting, further processing may include bending or punching holes into the studs for electrical wiring or plumbing needs—this versatility allows builders to customize their designs efficiently. Properly prepared coils ensure that each stud wall steel frame fits together seamlessly during assembly, minimizing waste and maximizing productivity throughout the construction phase. As such, this preparation stage is vital in achieving high-quality outcomes in metal framing.

Essential Tools and Equipment

To effectively execute metal framing projects, a variety of tools and equipment are necessary beyond just light gauge steel machines themselves. Basic tools include power drills for fastening components together securely as well as saws specifically designed for cutting through tough steel materials without compromising their integrity during assembly in a steel building framework. Additionally, measuring tapes and levels play crucial roles in ensuring accuracy throughout every stage.

Specialized equipment such as hydraulic punches may also be employed for creating holes in studs quickly while maintaining precision—a must-have when dealing with intricate designs involving electrical systems within walls made from stud wall steel frame constructions! Lastly, safety gear cannot be overlooked; hard hats and protective eyewear help safeguard workers while they navigate this dynamic environment filled with heavy materials like rolled-up coils ready for transformation into sturdy structures.

Kiant Machinery’s Role in Steel Construction

When it comes to building a steel building, Kiant Machinery stands out as a key player in the industry. They specialize in manufacturing light gauge steel machines that streamline the metal framing process, providing essential tools for modern construction. With their innovative technology and commitment to quality, they have become a trusted name in steel building construction.

Overview of Kiant Machinery’s Offerings

Kiant Machinery offers a comprehensive range of light gauge steel machines designed specifically for metal framing applications. Their product lineup includes advanced roll forming machines, which are essential for producing high-quality stud wall steel frame components efficiently. Not only do they provide machinery, but they also offer support and training to ensure customers can maximize their investment in steel coil processing.

Benefits of Their Advanced Technology

The benefits of Kiant Machinery’s advanced technology are numerous and impactful for anyone involved in steel building construction. Their light gauge steel machines enhance precision and reduce waste during the framing process, ultimately leading to cost savings on projects. Additionally, the durability and reliability of their equipment ensure that builders can focus on creating robust structures without worrying about equipment failures or inefficiencies.

Support in Building a Steel Building

Kiant Machinery goes beyond just supplying machines; they provide invaluable support throughout the entire process of building a steel building. From initial consultations to ongoing technical assistance, their team is dedicated to helping clients navigate the complexities of metal framing with ease. Whether it’s optimizing production workflows or troubleshooting issues with stud wall steel frame components, Kiant's commitment ensures that every project runs smoothly and successfully.

Conclusion

In the grand scheme of construction, steel stud framing stands out as a beacon of innovation and efficiency. The importance of steel stud framing cannot be overstated; it provides a robust framework that enhances the durability and longevity of structures. With light gauge steel machines at the forefront, building a steel building has never been more streamlined or effective.

Importance of Steel Stud Framing

Steel stud framing is crucial in modern construction due to its strength and versatility. Unlike traditional materials, which can warp or deteriorate over time, steel maintains its integrity under various conditions, making it ideal for metal framing applications. Furthermore, the use of light gauge steel machines simplifies the process of creating stud wall steel frames, ensuring precision and uniformity throughout any project.

Future Trends in Metal Framing

As we look ahead, several trends are shaping the future of metal framing in construction. The integration of advanced technologies, such as automation in light gauge steel machines and improved design software, is expected to revolutionize how we approach building a steel building. Additionally, sustainability will play an increasingly vital role; using recycled materials in steel building construction will likely become standard practice as industries strive for greener solutions.

Final Thoughts on Choosing Light Gauge Steel

Choosing light gauge steel for your next project is not just about aesthetics; it's about investing in a material that offers unparalleled strength and cost-effectiveness. With numerous benefits—such as lightweight yet strong structural support—light gauge steel stands out against traditional options like wood or concrete. Ultimately, when considering your options for metal framing and constructing a durable structure, investing in quality equipment like light gauge steel machines will pay off immensely.