Introduction

In the world of manufacturing, understanding laser cutting costs is crucial for making informed decisions. Whether you’re a seasoned professional or just starting out, knowing what influences these costs can help you choose the right technology and equipment for your needs. With the rise of advanced laser technologies, including fiber laser cutting machines and CO2 lasers, it’s essential to grasp how each option impacts overall expenses.

What Influences Laser Cutting Costs

Laser cutting costs are influenced by several factors, including material type, thickness, and setup complexity. For example, different materials such as metal or plastic may require varying levels of power and precision from a laser machine, directly affecting the price. Additionally, labor costs and the expertise required to operate a laser metal cutting machine play significant roles in determining overall expenses.

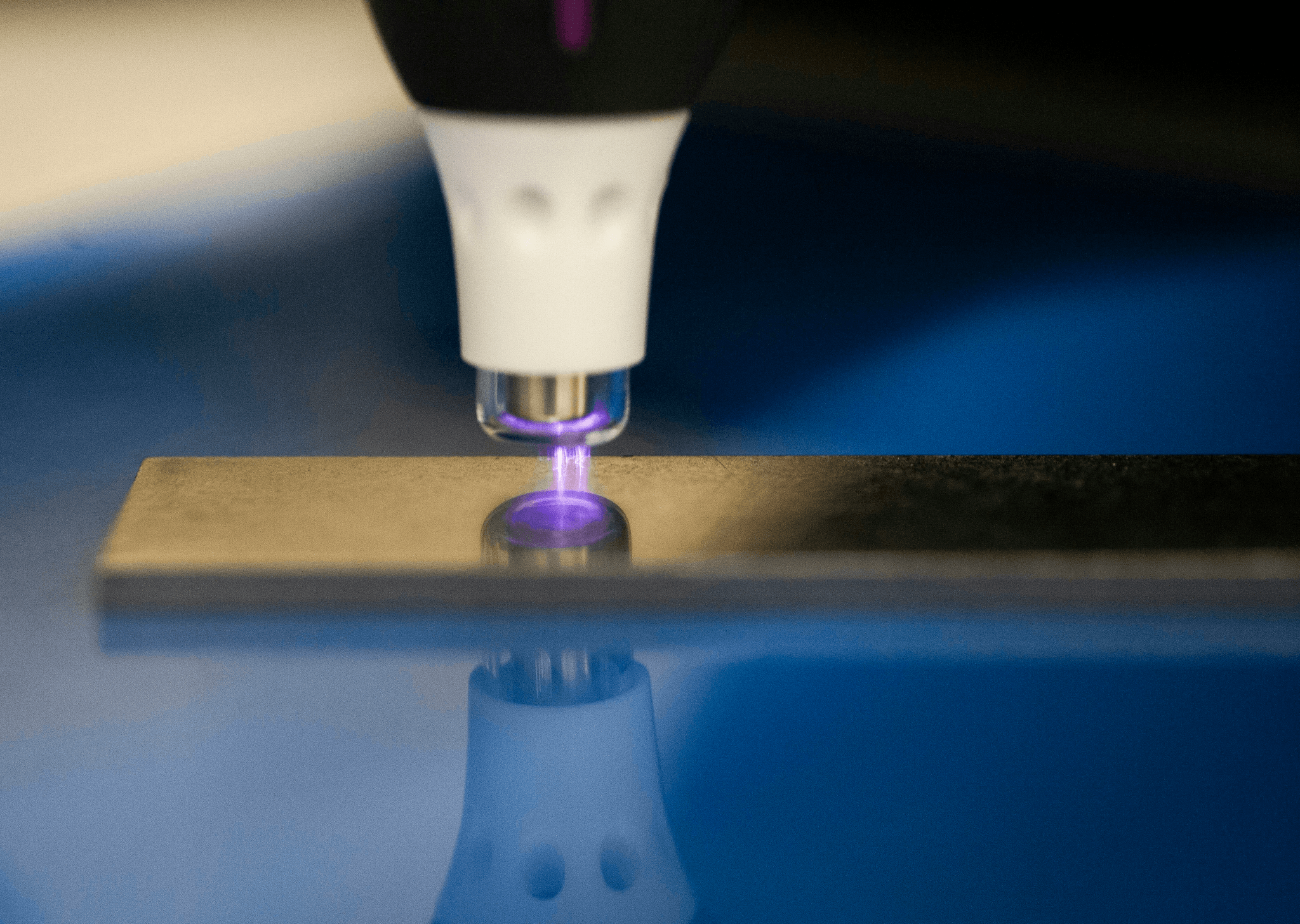

Overview of Laser Cutting Technologies

The landscape of laser cutting technologies is diverse, with options ranging from traditional CO2 lasers to modern fiber laser cutters. Each technology brings its own advantages and challenges; for instance, fiber lasers are often more efficient when working with metals compared to CO2 lasers. Understanding these differences is vital for manufacturers aiming to optimize their operations while keeping an eye on their budget.

The Benefits of Understanding Costs

Grasping the intricacies of laser machine prices can lead to better budgeting and investment decisions for businesses in need of precision cutting solutions. By understanding what contributes to laser cutting costs, companies can identify potential savings and improve their bottom line over time. Ultimately, being well-informed allows manufacturers to maximize value from their investments in laser technology without compromising on quality or efficiency.

Factors Affecting Laser Cutting Cost

Material Type and Thickness

The type of material being cut has a direct impact on laser cutting costs. Different materials, such as metals, plastics, or composites, require varying energy levels and settings on a laser machine to achieve optimal results. Additionally, the thickness of the material is crucial; thicker materials typically demand more powerful lasers and longer processing times, which can significantly increase the overall cost of using a fiber laser cutting machine or any other type of laser cutter.

For instance, when using a fiber laser cutter on stainless steel versus acrylic, the energy consumption and wear on the equipment will differ greatly. This means that manufacturers must take into account both material type and thickness when budgeting for their projects to avoid unexpected spikes in their laser cutting costs.

Setup Time and Complexity

Setup time is another critical factor affecting laser cutting costs that often gets overlooked. The complexity of the design being cut can lead to longer preparation times as operators configure settings for precision cuts. If intricate designs require multiple passes or adjustments during operation, this not only extends setup time but also increases labor costs associated with operating a laser metal cutting machine.

Moreover, if specialized fixtures or jigs are needed for specific projects, these can add additional expenses both in terms of time and materials required for setup. Thus, understanding how setup complexity correlates with overall project timelines is essential for accurately estimating total costs involved in using any kind of laser machine.

Labor Costs and Expertise

Labor costs are an integral part of calculating total laser cutting cost; skilled operators command higher wages due to their expertise with advanced technologies like fiber lasers or CO2 lasers. Efficiently running a fiber laser cutting machine requires trained personnel who understand how to optimize settings based on various materials and designs—this expertise comes at a premium but pays off through improved quality and reduced wastage.

Furthermore, ongoing training might be necessary as technology evolves or as new models enter the market with enhanced capabilities at different price points—this can further influence your budget considerations when looking at long-term operational expenses related to your chosen laser machines. Therefore, factoring in labor expertise alongside equipment pricing helps provide a clearer picture of what you’ll truly invest over time in your manufacturing processes.

Comparing Laser Cutting Technologies

When diving into the world of laser cutting, understanding the different technologies available is crucial for making informed decisions about your investment. The two most prominent types are fiber laser cutting and CO2 laser cutting, each with its own set of benefits and drawbacks that can significantly influence your overall laser cutting cost. By comparing these technologies, you can determine which option aligns best with your specific needs and budget.

Fiber Laser Cutting vs. CO2 Laser

Fiber laser cutting machines have gained popularity for their efficiency and versatility compared to traditional CO2 lasers. While CO2 lasers excel in cutting non-metal materials like wood and acrylic, fiber lasers shine in metal applications, offering faster speeds and higher precision on a variety of metals. This distinction not only affects performance but also impacts the overall laser machine price; fiber lasers tend to be more cost-effective in long-term operations due to lower maintenance needs.

In terms of operational costs, fiber laser cutters typically consume less energy than their CO2 counterparts, leading to reduced electricity expenses over time. Additionally, the setup time for fiber lasers is often quicker as they require less alignment and adjustment than CO2 machines. Understanding these differences can help businesses assess their potential savings regarding both initial investments and ongoing operational costs.

Advantages of Fiber Laser Machines

One major advantage of fiber laser machines is their ability to cut through thicker materials with ease while maintaining high-quality edges—a feature that appeals to industries focused on precision engineering and intricate designs. Moreover, these machines are generally more compact than CO2 systems, making them ideal for facilities with limited space without sacrificing performance or efficiency. As a result, many manufacturers find that investing in a fiber laser cutter leads to enhanced productivity without incurring excessive additional costs.

Another key benefit lies in their longevity; fiber lasers have fewer moving parts than traditional systems which translates into lower maintenance requirements and longer lifespans for the equipment—further driving down long-term laser cutting costs. When considering these advantages alongside the initial investment required for a quality fiber metal cutting machine, businesses can often justify the higher upfront price tag through significant savings over time. Ultimately, choosing a fiber laser cutter can be an excellent strategy for manufacturers looking to maximize value while minimizing operational headaches.

Cost Differences in Technology

When comparing the cost differences between fiber lasers and CO2 lasers, it's essential to consider not just the purchase price but also maintenance expenses and operating efficiencies over time. Typically, you might find that while CO2 machines may have lower initial prices on average, they often incur higher costs related to consumables such as lenses and mirrors that need regular replacement due to wear over time—ultimately affecting your bottom line when calculating total ownership costs.

On the other hand, investing in a high-quality fiber metal cutting machine may require a larger upfront capital outlay but offers substantial savings through reduced energy consumption and minimal upkeep requirements down the road—making it an attractive option for many manufacturers committed to long-term profitability strategies. Additionally, advancements in technology continue driving down prices for newer models of fiber cutters while enhancing capabilities further solidifying their position as leaders within this competitive market space.

In conclusion, understanding how different technologies affect your overall laser cutting cost is vital when making purchasing decisions about equipment like a new laser machine or upgrading existing setups with modern solutions such as a state-of-the-art fiber cutter or efficient CO2 system tailored specifically towards your production needs.

Understanding Laser Machine Prices

When diving into the world of laser cutting, understanding laser machine prices is crucial for making informed decisions. The cost of a laser metal cutting machine can vary significantly based on various factors, including technology, features, and brand reputation. By grasping current pricing trends, manufacturers can better align their budgets and expectations with the realities of the market.

Pricing Trends in the Market

In recent years, pricing trends for laser cutting machines have shown a gradual decline due to advancements in technology and increased competition among manufacturers. Fiber laser cutters have become particularly popular because they offer superior efficiency and lower operational costs compared to traditional CO2 lasers. As production processes evolve, businesses are increasingly looking at long-term investments in laser technology that promise better returns while keeping overall laser cutting costs manageable.

Popular Models and Their Costs

Several models dominate the market when it comes to fiber laser cutting machines and CO2 lasers alike. For instance, entry-level fiber laser cutters can start around $30,000, while more advanced models may reach upwards of $150,000 or more depending on their capabilities. Manufacturers often weigh these prices against the potential savings in operational costs over time to determine which model best fits their needs without breaking the bank.

How to Budget for Your Laser Machine

Budgeting for your new laser machine requires careful consideration of both initial costs and ongoing expenses associated with operation and maintenance. Begin by assessing your specific needs—what materials will you be cutting? This will help narrow down your options between models like a fiber laser cutter or CO2 system while estimating total ownership costs over time. Don’t forget to include training expenses for staff and any necessary upgrades or accessories that could enhance your machine’s performance.

The Role of Kiant Machinery in Your Decision

When navigating the landscape of laser cutting technology, choosing the right machinery can significantly impact your overall laser cutting cost. Kiant Machinery stands out as a reliable partner in this journey, providing not only high-quality equipment but also valuable insights into the intricacies of laser metal cutting machines. Their commitment to customer satisfaction and understanding of the market make them a top choice for manufacturers looking to optimize their operations.

Why Choose Kiant Machinery

Kiant Machinery has established itself as a leader in the field of laser cutting solutions, with a diverse range of products tailored to meet various manufacturing needs. Their fiber laser cutting machines are designed for efficiency and precision, ensuring that you get the best performance without breaking the bank on your laser machine price. With a solid reputation built on quality and reliability, choosing Kiant means investing in technology that will pay dividends over time.

Moreover, their team is dedicated to keeping up with industry trends and advancements, which allows them to offer innovative solutions that can help lower your overall laser cutting costs. Whether you’re interested in acquiring a fiber laser cutter or upgrading your existing setup, Kiant Machinery provides options that align with both budgetary constraints and operational goals. By opting for their products, you’re not just buying machinery; you’re gaining a partner invested in your success.

Cost-Effective Solutions for Manufacturers

One of the standout features of Kiant Machinery is their ability to deliver cost-effective solutions tailored specifically for manufacturers facing tight margins or fluctuating demand. Their range includes various models of laser metal cutting machines that cater to different material types and thicknesses—ensuring versatility without compromising on quality or performance. This adaptability helps businesses manage their laser cutting costs more effectively while still achieving exceptional results.

Kiant’s focus on providing value extends beyond just competitive pricing; they also emphasize efficiency through advanced technology integration within their fiber laser cutters. These innovations not only enhance productivity but also reduce operational expenses over time—a win-win situation for any manufacturer looking to maximize returns on investment. By choosing Kiant Machinery, you're ensuring that every dollar spent contributes positively towards enhancing your manufacturing capabilities.

Support and Guidance in Equipment Selection

Selecting the right equipment can be daunting given the myriad options available today; however, Kiant Machinery offers unparalleled support throughout this process. Their knowledgeable team assists customers in evaluating specific needs related to production volume, material types, and desired outcomes—all critical factors influencing both immediate purchases and long-term operational strategies concerning laser machine prices. With this level of guidance at hand, businesses can confidently choose machinery that aligns perfectly with their requirements.

Furthermore, Kiant provides ongoing support even after purchase—ensuring users are well-acquainted with their new fiber laser cutting machines through training sessions and resource materials designed for optimal utilization. This commitment doesn’t just enhance user experience; it directly impacts operational efficiency by minimizing downtime due to mismanagement or lack of knowledge about equipment functionalities related to cost savings initiatives involving efficient use practices across all aspects involved in managing overall production processes effectively.

In conclusion, when it comes down to making informed decisions regarding investments into advanced technologies like those offered by Kiant Machinery—understanding how each component influences total costs becomes paramount!

Long-Term Cost Considerations

When investing in a laser cutting machine, it's crucial to think beyond the initial purchase price. Long-term costs, including maintenance and operational expenses, can significantly impact the overall laser cutting cost. Understanding these factors will help you make informed decisions and maximize your investment in a laser metal cutting machine.

Maintenance and Operational Costs

Laser machines, like any sophisticated equipment, require regular maintenance to ensure optimal performance. This includes routine checks on components such as lenses, mirrors, and cooling systems to prevent costly breakdowns that could halt production. Additionally, operational costs—such as energy consumption and replacement parts—play a vital role in determining the total laser cutting cost over time; a fiber laser cutter is known for its efficiency but still requires careful budgeting for upkeep.

Potential Savings with Efficiency

One of the significant advantages of modern laser cutting technologies is their efficiency, which can lead to substantial savings over time. Fiber laser cutting machines are particularly adept at reducing waste material during the cutting process compared to traditional methods; less waste means more savings! Furthermore, faster processing times translate into higher productivity levels, allowing manufacturers to take on more projects without incurring additional labor costs—a win-win situation that effectively lowers overall laser cutting expenses.

Resale Value of Laser Machines

When considering the long-term financial implications of purchasing a laser machine, it’s essential to factor in resale value. High-quality machines like fiber laser cutters tend to retain their value better than older or less efficient models; this means you might recoup a significant portion of your initial investment when it’s time for an upgrade or change in technology. Keeping your equipment well-maintained not only extends its lifespan but also enhances its appeal on the resale market—ultimately reducing your net laser cutting cost.

Conclusion

In the world of manufacturing, understanding laser cutting costs is crucial for making informed decisions. By considering all the factors that influence these costs—from material type to labor expertise—you can better navigate your investment in laser technology. Whether you’re eyeing a fiber laser cutting machine or weighing options for a CO2 laser, knowledge is power.

Making Informed Decisions on Costs

The initial price of a laser metal cutting machine may seem like the most significant expense, but ongoing operational and maintenance costs can add up quickly. By evaluating all aspects of laser cutting cost, including setup time and material choices, you’ll be better prepared to choose the right equipment for your needs.

Future Trends in Laser Cutting

As technology continues to evolve, so do the capabilities and efficiencies of laser cutting machines. Innovations in fiber lasers are paving the way for faster processing times and lower energy consumption, which could significantly reduce overall laser cutting costs in the future. Staying ahead of these trends will not only enhance your production capabilities but also ensure that you're maximizing your investment.

Maximizing Value with Laser Technology

To truly capitalize on your investment in a fiber laser cutter or any other type of laser machine, consider both immediate and long-term value. This means not just focusing on purchase price but also assessing potential savings from efficiency improvements and reduced waste over time. By choosing reputable brands like Kiant Machinery and understanding market pricing trends, you can optimize your operations while keeping an eye on overall laser cutting cost.