Introduction

In the ever-evolving landscape of construction, light gauge steel framing has emerged as a game-changer, offering a robust alternative to traditional wood framing. This innovative approach to steel building construction utilizes thin sheets of steel that are cold-formed into various shapes and sizes, making it an attractive choice for both residential and commercial projects. As we delve deeper into the intricacies of light gauge steel construction, it becomes clear that precision and efficiency are paramount in modern building practices.

Overview of Light Gauge Steel Framing

Light gauge steel framing is a method that employs lightweight steel sections to create structural frameworks for buildings. Unlike conventional wood framing, which can warp or decay over time, this method relies on the inherent strength and durability of steel for framing. The result is a resilient structure capable of withstanding various environmental challenges while providing builders with greater design flexibility.

Importance of Precision in Construction

Precision in construction cannot be overstated; it directly influences the safety and longevity of any structure built using light gauge steel construction techniques. Inaccurate measurements or misalignments can lead to costly repairs down the line, making meticulous attention to detail essential during the building process. With advancements in technology, including automated machinery designed specifically for metal framing, achieving this level of precision has never been more attainable.

Efficiency in Modern Building Practices

The efficiency offered by light gauge steel framing contributes significantly to faster project completion times and reduced labor costs compared to traditional methods like wood framing. By utilizing prefabricated components that can be quickly assembled on-site, builders can streamline their operations without sacrificing quality or safety standards. This shift towards more efficient practices not only benefits contractors but also leads to enhanced sustainability in the overall construction process.

What is Light Gauge Steel Framing?

Light gauge steel framing is a modern construction method that utilizes thin sheets of steel to create structural components for buildings. This innovative approach has gained popularity due to its strength, versatility, and efficiency compared to traditional building methods. As the demand for sustainable and durable materials grows, light gauge steel construction stands out as a compelling choice for both residential and commercial projects.

Definition and Characteristics

Light gauge steel framing refers to the use of cold-formed steel sections that are typically less than 1/4 inch thick. These sections are shaped into various profiles, allowing them to serve as studs, tracks, and other essential components in the framing process. The lightweight nature of these materials makes them easy to handle while still providing exceptional strength and stability necessary for robust construction.

Comparison with Wood Framing

When comparing light gauge steel construction with wood framing, several key differences emerge that highlight the advantages of using metal framing. First off, wood tends to warp or shrink over time due to moisture changes, whereas steel maintains its shape and integrity regardless of environmental factors. Additionally, light gauge steel is generally more fire-resistant than wood, making it a safer option in many applications; this translates into lower insurance premiums for property owners.

Benefits of Steel for Framing

The benefits of using steel for framing extend beyond mere durability; they encompass cost-effectiveness over time as well. Unlike traditional wood framing that may require frequent repairs or replacements due to pests or rot, light gauge steel construction offers a long-lasting solution with minimal maintenance needs. Furthermore, because it can be fabricated off-site with precision machinery, projects utilizing metal framing often experience reduced labor costs and shorter build times—an attractive proposition in today’s fast-paced construction industry.

Advantages of Light Gauge Steel Construction

When it comes to modern building practices, light gauge steel construction stands out for its numerous advantages. This innovative approach offers a range of benefits that make it increasingly popular among builders and architects alike. From durability to cost-effectiveness, the merits of steel framing are hard to ignore.

Durability and Longevity

Light gauge steel construction is renowned for its exceptional durability and longevity, outpacing traditional wood framing in many respects. Unlike wood, which can warp, crack, or succumb to pests over time, steel for framing retains its structural integrity for decades. The resilience of metal framing makes it an ideal choice for projects where long-term performance is essential.

Resistance to Environmental Factors

One of the standout features of steel building construction is its unparalleled resistance to environmental factors. Whether it's extreme temperatures, moisture, or pest infestations, light gauge steel can withstand harsh conditions without compromising structural integrity. This inherent strength not only extends the lifespan of a structure but also significantly reduces maintenance costs associated with wood framing.

Cost-Effectiveness Over Time

While the initial investment in light gauge steel construction might be higher than wood framing, the long-term savings are undeniable. Steel building construction minimizes repair and replacement costs due to its durability and resistance to environmental challenges. Ultimately, opting for steel framing leads to greater cost-effectiveness over time as property owners enjoy lower maintenance expenses and enhanced property value.

The Role of Technology in Steel Framing

In the world of light gauge steel construction, technology plays a pivotal role in enhancing efficiency and precision. The integration of advanced machinery has revolutionized the way steel framing is executed, making it not only faster but also more reliable than traditional wood framing methods. As we delve into this section, we'll explore how these technological advancements are shaping the future of steel building construction.

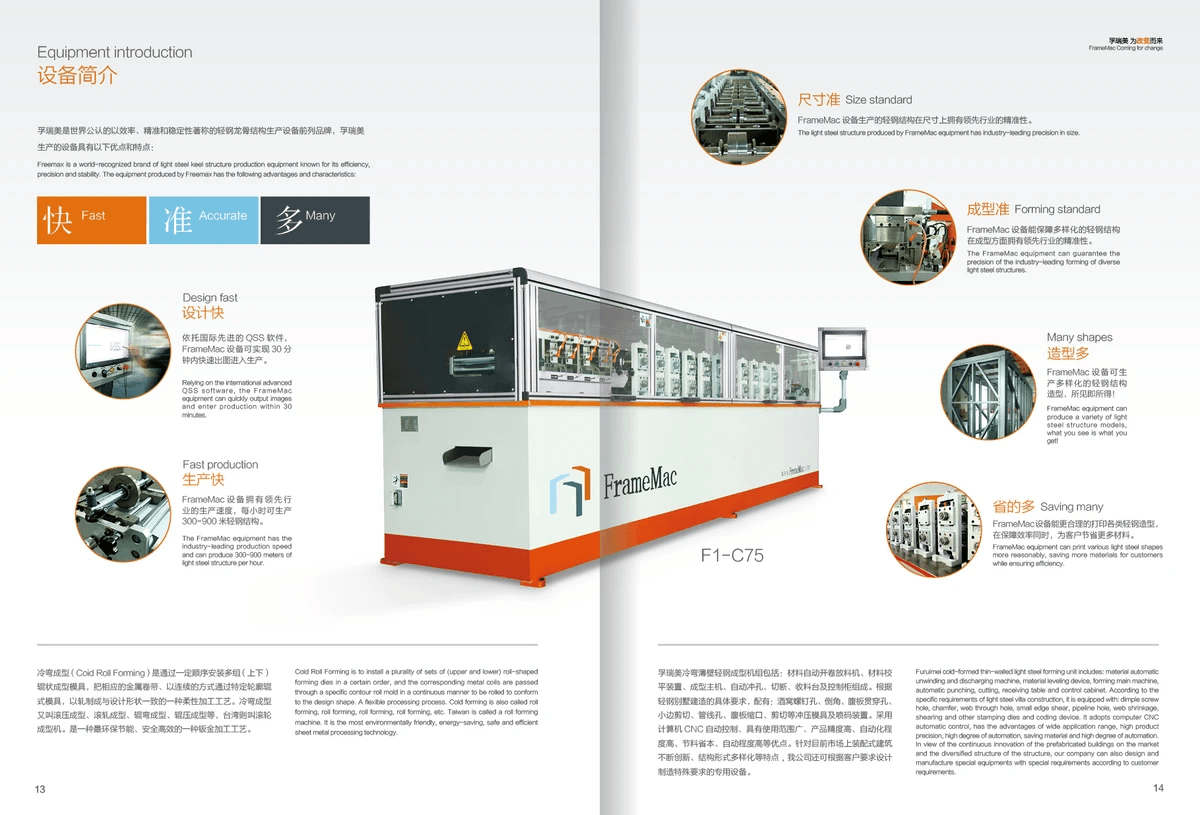

Advanced Machinery and Equipment

The backbone of modern steel framing lies in advanced machinery and equipment designed specifically for light gauge steel construction. These machines streamline processes such as cutting, bending, and assembling framing steel building components with unparalleled accuracy. By utilizing sophisticated tools like CNC (Computer Numerical Control) machines, builders can achieve intricate designs that would be nearly impossible with conventional wood framing techniques.

Moreover, this advanced equipment significantly reduces labor costs and time on-site, allowing for quicker project completion without compromising quality. In an industry where every second counts, having reliable machinery ensures that metal framing projects stay on track and within budget. This approach not only enhances productivity but also contributes to the overall cost-effectiveness of steel building construction over time.

Kiant Machinery’s Innovations

Kiant Machinery has emerged as a key player in the realm of light gauge steel construction by introducing innovative solutions tailored for efficient steel framing practices. Their cutting-edge technologies include automated roll-forming systems that create precise components while minimizing material waste—an essential aspect when considering sustainability in metal framing projects. With Kiant's innovations, builders can enjoy increased versatility and adaptability in their designs without sacrificing structural integrity.

Additionally, Kiant Machinery focuses on user-friendly interfaces that simplify operation for workers at all skill levels. This accessibility fosters a smoother transition from traditional methods to modern techniques among contractors who may initially be hesitant about moving away from wood framing options. Ultimately, Kiant's contributions are helping to pave the way for a new era in steel building construction where efficiency reigns supreme.

Automation and Efficiency Gains

Automation is transforming how we approach light gauge steel construction by enhancing efficiency gains across various stages of the building process. Automated systems not only speed up production but also ensure consistent quality control throughout each phase—from manufacturing to installation of the final product in a framing steel building project. This level of precision is particularly crucial when comparing against more variable wood framing methods that can be susceptible to human error.

Furthermore, automation allows for better resource management by optimizing material usage and reducing waste—a significant concern within any construction endeavor today. As builders increasingly embrace these technologies within their workflows, they find themselves reaping substantial benefits through reduced labor costs and improved timelines for project completion in commercial settings as well as residential developments alike.

Applications of Light Gauge Steel Framing

Light gauge steel construction is rapidly becoming a preferred method in various sectors, showcasing its versatility and robustness. This innovative approach is reshaping how we think about building, whether for homes or commercial spaces. As we delve into its applications, it’s clear that steel framing is not just a trend but a sustainable solution for modern construction.

Residential Construction Trends

In the realm of residential construction, light gauge steel framing is gaining traction as homeowners seek durable and energy-efficient solutions. Unlike traditional wood framing, which can be susceptible to pests and rot, steel for framing offers unparalleled longevity and resilience. This shift towards light gauge steel construction reflects a growing appreciation for materials that stand the test of time while providing design flexibility.

Moreover, builders are increasingly incorporating metal framing into eco-friendly projects, aligning with sustainability goals without compromising on aesthetics or strength. With advancements in technology, constructing homes using light gauge steel has become more efficient and cost-effective than ever before. As trends continue to evolve, expect to see more residential neighborhoods featuring innovative designs supported by robust steel building construction.

Commercial Steel Building Construction

The commercial sector has embraced light gauge steel framing due to its structural integrity and adaptability to diverse designs. Steel building construction allows architects to create expansive spaces without the need for numerous support columns typical with wood framing systems. This open layout not only enhances functionality but also provides an appealing aesthetic that attracts businesses and clients alike.

Additionally, the speed of assembly associated with metal framing makes it an attractive option for commercial projects where time is often of the essence. Businesses can move into new facilities faster thanks to the efficiency offered by advanced techniques in light gauge steel construction. With rising demand for flexible workspaces and retail environments, it's evident that steel framing will play a pivotal role in shaping tomorrow's commercial landscapes.

Versatility in Metal Framing Projects

One of the standout features of light gauge steel construction is its remarkable versatility across various types of projects—from industrial warehouses to educational institutions. The inherent strength of metal framing allows it to adapt seamlessly to different architectural styles while maintaining structural performance under varying loads and conditions. Whether it’s creating multi-story buildings or single-story expansions, using steel for framing provides endless possibilities.

Moreover, this adaptability extends beyond just design; it also encompasses environmental factors such as seismic resistance and fire safety—a crucial consideration in many regions today. As industries evolve and face new challenges like climate change or urbanization pressures, the role of light gauge steel will only become more prominent in future constructions worldwide. Ultimately, embracing this versatile material means investing in long-term solutions that benefit builders and end-users alike.

The Future of Steel Framing

The future of steel framing is bright, with innovative technologies poised to revolutionize the construction industry. As light gauge steel construction becomes more mainstream, builders are turning to advanced machinery and techniques that enhance precision and efficiency. This shift not only improves the quality of steel building construction but also sets a new standard for durability and design.

Emerging Technologies in Construction

Emerging technologies are reshaping how we approach steel framing, making it more efficient than ever before. From 3D modeling software to robotic automation, these advancements allow for precise cuts and fittings that were once labor-intensive processes in wood framing. By leveraging these innovations, contractors can significantly reduce waste and improve project timelines in metal framing applications.

Moreover, the integration of Building Information Modeling (BIM) is transforming how teams collaborate on steel building projects. BIM enables real-time updates and adjustments, ensuring that all stakeholders are on the same page throughout the construction process. As these technologies continue to evolve, they will undoubtedly enhance the capabilities of steel for framing in various applications.

Shift Towards Steel in Modern Architecture

There’s a noticeable shift towards using steel for framing in modern architecture, driven by its aesthetic versatility and structural integrity. Architects are increasingly embracing light gauge steel construction for its ability to support complex designs while providing open spaces without compromising strength. This trend has led to innovative structures that highlight both functionality and visual appeal.

Additionally, as cities become denser and land becomes more valuable, architects are turning to vertical designs supported by robust steel frames. This allows for taller buildings with larger floor areas while maintaining safety standards that wood framing may struggle to meet under similar conditions. The result is a new era where metal framing isn’t just a practical choice but also an artistic one.

Sustainability in Steel Building Steel

Sustainability is at the forefront of discussions surrounding future construction practices, including light gauge steel construction. Steel is inherently recyclable; this characteristic makes it an environmentally friendly option compared to traditional materials like wood framing which can contribute to deforestation issues. Moreover, advancements in production processes have made it possible to create stronger yet lighter forms of metal framing that require less material overall.

As awareness about climate change grows, builders are increasingly seeking sustainable solutions like green certifications for their projects involving steel building constructions. These initiatives often focus on energy efficiency during both the building process and throughout the structure's lifecycle—making buildings not just sturdy but also eco-conscious investments over time. By prioritizing sustainability within steel framing practices, we can pave the way toward a greener future.

Conclusion

In wrapping up our exploration of light gauge steel construction, it's clear that this method offers a host of benefits that cannot be overlooked. From its durability and resistance to environmental factors to its cost-effectiveness over time, light gauge steel framing stands out as a superior choice compared to traditional wood framing. The advantages of using steel for framing are not just theoretical; they are backed by real-world applications and innovations that continue to evolve.

Recap of Light Gauge Steel Benefits

Light gauge steel construction provides significant longevity, making it an appealing option for builders and homeowners alike. Unlike wood framing, which can be susceptible to pests and rot, steel framing is robust and resistant to many environmental challenges. This inherent durability translates into lower maintenance costs over time, reinforcing the notion that investing in steel building construction is a wise financial decision.

The Growing Market for Steel Framing

The market for metal framing is on the rise as more builders recognize the advantages of using light gauge steel in their projects. With increasing demand across residential and commercial sectors, the shift toward steel building construction reflects a broader trend towards sustainability and efficiency in architecture. As urban areas expand and require innovative solutions, the versatility of steel for framing positions it as a frontrunner in modern construction practices.

Final Thoughts on Efficient Construction Solutions

As we look ahead, it's evident that light gauge steel construction will play a pivotal role in shaping the future of building practices. The integration of advanced technology into steel framing processes promises even greater efficiency gains, making it an attractive option for developers seeking sustainable solutions without compromising quality or aesthetics. Ultimately, embracing light gauge steel not only enhances structural integrity but also aligns with a vision for smarter, more efficient construction solutions.