Introduction

In the rapidly evolving landscape of manufacturing, traditional methods of metal cutting are being revolutionized by advanced technologies. The introduction of the laser pipe cutting machine has transformed how industries approach precision and efficiency in metal processing. With its ability to deliver high-quality cuts with minimal waste, this technology is setting new standards for industrial laser cutting.

Revolutionizing Metal Cutting

The advent of the metal cutting laser cutter marks a significant shift in manufacturing capabilities. Unlike conventional cutting methods, which can be slow and imprecise, the laser cutting machine offers unparalleled accuracy and speed. This revolution not only enhances productivity but also reduces operational costs, making it an attractive option for manufacturers looking to stay competitive.

The Rise of Automation in Manufacturing

Automation is becoming increasingly essential in modern manufacturing environments, driving the need for innovative solutions like industrial laser cutters. By integrating automated systems with laser technology, companies can streamline their operations and minimize human error during metal cutting processes. This rise in automation is not just a trend; it's a necessary evolution that allows manufacturers to meet growing demands while maintaining quality.

How Laser Technology is Transforming Industries

Laser technology is at the forefront of transforming various industries, from automotive to aerospace and beyond. The versatility of the industrial laser cutting machine enables it to tackle complex designs and materials that were once challenging to process efficiently. As more businesses recognize the benefits of adopting these advanced tools, we can expect a continued evolution in how metal components are produced across sectors.

Overview of Metal Laser Pipe Cutting Machines

In the realm of modern manufacturing, the laser pipe cutting machine stands out as a game-changer. This sophisticated piece of equipment utilizes high-powered lasers to cut through various types of metal pipes with exceptional precision and speed. By leveraging advanced technology, these machines are transforming how industries approach metal fabrication and processing.

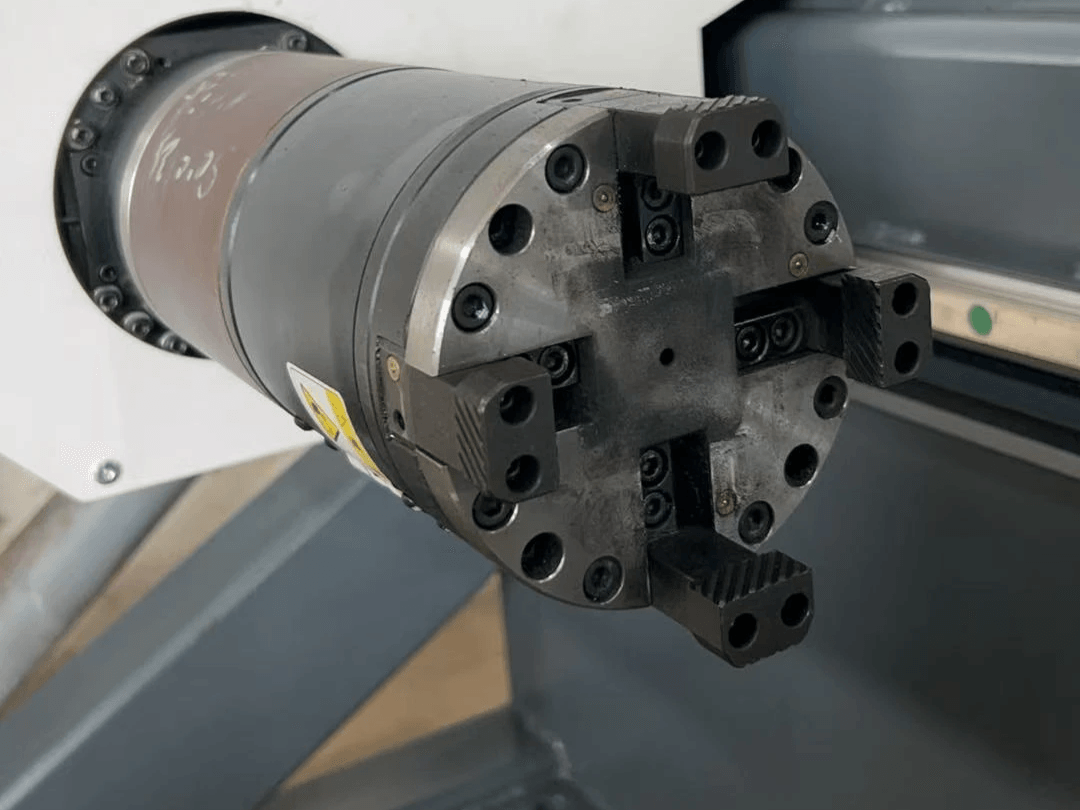

What is a Laser Pipe Cutting Machine?

A laser pipe cutting machine is an industrial laser cutter designed specifically for slicing through metal pipes and tubes with remarkable accuracy. Utilizing focused laser beams, this machine can create intricate shapes and cuts that would be difficult or impossible to achieve with traditional methods. From stainless steel to aluminum, the versatility of the metal cutting laser cutter makes it an invaluable asset in any manufacturing setup.

The heart of a laser pipe cutting machine lies in its ability to control the intensity and focus of the laser beam, allowing for clean cuts without excessive heat or distortion. This level of control not only enhances the quality of the finished product but also minimizes waste material during production. As industries continue to seek efficiency and precision, understanding what a laser pipe cutting machine offers becomes increasingly crucial.

Advantages of Industrial Laser Cutting Machines

Industrial laser cutting machines offer numerous advantages that make them preferable over conventional methods. Firstly, they provide unmatched precision in cuts, ensuring that even the most complex designs are executed flawlessly every time. Additionally, these machines operate at high speeds, significantly reducing production times while maintaining quality standards—an essential factor in today’s fast-paced market.

Another significant advantage is their flexibility; a single metal cutting machine laser can handle various materials and thicknesses without needing extensive reconfiguration or tooling changes. This adaptability not only streamlines operations but also allows manufacturers to respond quickly to changing demands or custom orders. Furthermore, less manual intervention means lower labor costs and reduced risk of human error—making industrial laser cutters a smart investment for any business looking to enhance productivity.

Applications in Different Industries

The applications for laser pipe cutting machines span across numerous industries, showcasing their versatility and effectiveness in various contexts. In construction and architecture, these machines are used to create precise components for structural frameworks or decorative elements that require intricate detailing—a testament to their ability to deliver both functionality and aesthetic appeal.

Manufacturing sectors such as automotive and aerospace also heavily rely on industrial laser cutting technologies for producing complex parts with tight tolerances needed for safety-critical applications like engine components or airframe structures. Moreover, industries involved in HVAC systems use these machines extensively for fabricating ductwork with exact specifications—further demonstrating how integral they have become across diverse fields.

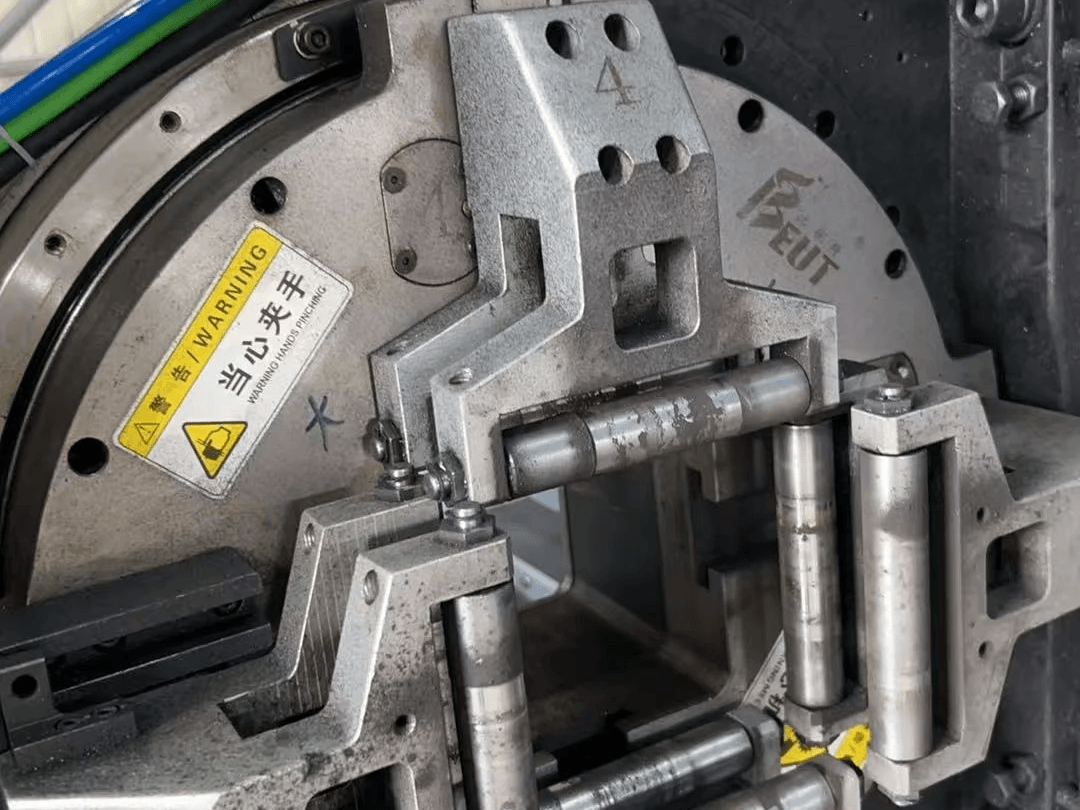

The Automatic Feeding System Explained

In the realm of industrial laser cutting, the automatic feeding system is a game-changer that enhances productivity and precision. By automating the material handling process, this system minimizes downtime and maximizes throughput, allowing for uninterrupted workflows in laser pipe cutting machines. As manufacturers strive for efficiency, integrating an automatic feeding system into their metal cutting machines has become essential.

How Automatic Feeding Enhances Efficiency

The automatic feeding system significantly boosts efficiency by streamlining the loading and unloading of materials in laser cutting operations. With precise control over material flow, industrial laser cutters can maintain high-speed production without constant manual intervention. This not only reduces labor costs but also mitigates human error, ensuring that every cut made by the metal cutting laser cutter is accurate and consistent.

Moreover, these systems can handle various sizes and types of materials, making them versatile additions to any manufacturing setup. For instance, a well-designed automatic feeding mechanism allows a laser metal cutting machine to switch seamlessly between different pipe dimensions without requiring extensive reconfiguration. This adaptability ensures that production lines remain flexible and responsive to changing demands.

Key Features of Automatic Feeding Systems

Automatic feeding systems come equipped with several key features designed to optimize performance in industrial settings. One prominent feature is sensor technology that monitors material levels and automatically replenishes stock when necessary, preventing interruptions during laser cutting processes. Additionally, many systems include programmable controls that allow operators to set specific parameters for different projects on their laser cutting machines.

Another important aspect is compatibility with various types of metal cutting machines; whether it’s a compact model or an expansive industrial laser cutter, these systems integrate smoothly into existing setups. Furthermore, some advanced models offer real-time data analytics capabilities that provide insights into performance metrics and operational efficiencies—information invaluable for continuous improvement in production workflows.

Real-world Benefits in Production

The real-world benefits of implementing an automatic feeding system in metal cutting operations are substantial and multifaceted. First off, businesses experience increased output rates as automated processes eliminate bottlenecks typically caused by manual material handling during laser cutting tasks. This translates directly into higher profitability as companies can meet greater demand without compromising quality or speed.

Furthermore, enhanced safety measures come into play when using automated systems; reducing human interaction with heavy materials minimizes workplace accidents associated with manual handling techniques often seen in traditional settings using industrial laser cutting machines. Lastly, companies adopting these technologies report improved employee morale since staff can focus on more skilled tasks rather than repetitive manual labor—leading to greater job satisfaction overall.

Comparing Laser Cutting Technologies

In the world of laser cutting, two technologies stand out: CO2 and fiber lasers. Understanding the differences between these two types is crucial for manufacturers looking to invest in a laser pipe cutting machine or an industrial laser cutter. Each technology has its own strengths and weaknesses, which can significantly impact efficiency and output quality.

CO2 vs. Fiber Laser Cutting Machines

CO2 lasers have been around for decades, utilizing a gas mixture to produce a high-quality beam suitable for various materials. They excel at cutting thicker materials but often require more maintenance than their fiber counterparts. On the other hand, fiber laser cutting machines have gained popularity due to their energy efficiency, compact size, and ability to cut through metals with exceptional precision.

When it comes to speed and operational costs, the metal cutting machine laser shows that fiber lasers tend to outperform CO2 lasers in most scenarios. This makes them particularly appealing for industries focused on high-volume production where time is money. However, if you primarily work with non-metal materials or thicker metals, a CO2 laser might still be your best bet.

Ultimately, the choice between CO2 and fiber lasers depends on your specific needs—material type, thickness requirements, and budget considerations all play vital roles in this decision-making process. Investing in an industrial laser cutting machine that aligns with your operational goals will enhance productivity while ensuring quality output.

Choosing the Right Metal Cutting Laser Cutter

Selecting the right metal cutting laser cutter involves more than just picking a brand; it’s about understanding your production requirements first. Consider factors such as material types you'll be working with—aluminum versus steel—and thickness ranges that need attention from your new machinery. The right choice will not only improve efficiency but also reduce waste and downtime during operations.

Another critical aspect is evaluating the features of different models available on the market today. Look for capabilities like automatic feeding systems or advanced software that can optimize cut paths for better precision with each pass of your industrial laser cutter. These enhancements can make a significant difference in overall performance and reliability over time.

Don’t forget about after-sales support! Partnering with manufacturers who offer robust customer service ensures you won’t be left stranded if issues arise post-purchase—a crucial consideration when investing in any metal cutting machine laser technology.

Efficiency and Precision in Laser Cutting

Efficiency is key when it comes to choosing a laser cutting machine; after all, no one wants their production line slowed down by inefficiencies! With advancements in technology like automatic feeding systems incorporated into modern designs of industrial laser cutters, operations are streamlined significantly compared to older models without such features. This means quicker turnaround times while maintaining high standards of quality throughout each project phase.

Precision is equally important—after all, what good is speed if you’re not achieving accurate cuts? The latest innovations allow metal cutting machines to achieve tolerances previously thought impossible within manufacturing processes across various industries—from automotive parts production to intricate artistic designs made from steel sheets!

Investing wisely means finding solutions that strike an ideal balance between speed and accuracy so every job completed meets client expectations without compromising on quality or delivery timelines.

Kiant Machinery: Leading the Way

Kiant Machinery stands at the forefront of innovation in the realm of laser cutting technology. With a rich history and extensive expertise, this company has established itself as a leader in manufacturing high-quality laser pipe cutting machines and other industrial laser cutting solutions. Their commitment to excellence ensures that manufacturers can rely on them for state-of-the-art metal cutting machines that enhance productivity and precision.

Company Background and Expertise

Founded by industry veterans, Kiant Machinery has evolved into a powerhouse in the field of laser metal cutting technology. Their team possesses deep knowledge of various applications for industrial laser cutters, allowing them to tailor solutions that meet specific customer needs. This expertise is reflected in their wide range of products, including advanced metal cutting machines designed to deliver exceptional performance.

Kiant Machinery's commitment to research and development sets it apart from competitors. They invest heavily in exploring new technologies and improving existing ones, ensuring their customers receive the best possible equipment for their operations. By staying ahead of trends in laser cutting technology, they continue to lead the charge toward more efficient manufacturing processes.

Innovative Solutions for Manufacturers

At Kiant Machinery, innovation is not just a buzzword; it's a core principle that drives every project they undertake. The company offers an impressive lineup of industrial laser cutting machines equipped with advanced features designed to streamline production workflows. From automatic feeding systems to intuitive software interfaces, these innovations significantly enhance the capabilities of any manufacturing facility.

Their flagship products include versatile metal cutting laser cutters capable of handling various materials with ease and precision. This adaptability makes them ideal for industries ranging from automotive to aerospace, where precision is paramount. By integrating innovative technologies into their laser pipe cutting machines, Kiant empowers manufacturers to push boundaries and achieve new levels of efficiency.

Customer Support and After-sales Services

Kiant Machinery understands that investing in a metal cutting machine laser is just the beginning; ongoing support is crucial for sustained success. Their customer service team is dedicated to providing comprehensive assistance throughout the lifecycle of their products. From installation guidance to troubleshooting support, clients can count on prompt responses and expert advice whenever needed.

Moreover, Kiant offers tailored training programs designed specifically for operators of their industrial laser cutters. This ensures that users are well-equipped with the knowledge necessary to maximize machine performance while minimizing downtime due to operator error or misunderstanding features. With robust after-sales services, Kiant reinforces its reputation as a partner committed not only to selling machinery but also ensuring long-term satisfaction.

Cost Considerations for Investing in Laser Machines

Investing in a laser cutting machine is no small feat, and understanding the financial implications is crucial for any manufacturer. While the upfront costs may seem daunting, the long-term savings from enhanced efficiency and reduced waste can be significant. This section will explore the balance between initial investment and future returns when considering a metal cutting laser cutter.

Upfront Costs vs. Long-term Savings

When purchasing an industrial laser cutting machine, the initial price tag can be quite high, often making businesses hesitate. However, it's essential to look beyond that upfront cost and consider how a laser pipe cutting machine can streamline operations over time. With lower operational costs due to reduced material waste and faster production speeds, many companies find that their investment pays off sooner than expected.

Additionally, modern laser metal cutting machines often come equipped with advanced technology that minimizes energy consumption while maximizing output quality. This means that while you might spend more initially on a high-quality metal cutting machine laser, your monthly bills could significantly decrease as efficiencies improve. In the end, it’s all about weighing those first expenses against what you’ll save down the road.

Factors Influencing the Cost of Metal Cutting Machines

Several factors contribute to the overall cost of a metal cutting laser cutter beyond just its base price tag. The type of technology used—be it CO2 or fiber lasers—can greatly affect costs; fiber lasers tend to have higher upfront prices but offer better efficiency in many cases. Additionally, features such as automatic feeding systems or advanced software integrations can also drive up costs but may provide notable benefits in productivity.

Another important consideration is maintenance and operational requirements; some industrial laser cutters require more frequent upkeep than others which can lead to hidden expenses over time. Furthermore, market conditions and supplier relationships can influence pricing as well; staying informed about trends in manufacturing technology helps ensure you’re making a wise decision regarding your investment in an industrial laser cutting machine.

ROI from Automated Metal Cutting Solutions

Calculating return on investment (ROI) for automated solutions like a laser pipe cutting machine involves looking at various metrics such as production speed, labor costs saved, and material utilization rates. Businesses that adopt these advanced technologies often see significant reductions in labor needs because automated systems require less manual intervention compared to traditional methods of metal cutting.

Moreover, improved precision means fewer errors during production runs which translates into less scrap material—a direct hit to waste reduction efforts! When evaluating ROI from your metal cutting machines—especially those equipped with automation features—it’s crucial to factor in not only immediate savings but also long-term gains through enhanced capabilities and streamlined processes.

Conclusion

As we stand on the brink of a new era in manufacturing, the advancements in metal cutting technologies are nothing short of revolutionary. The rise of laser cutting machines, particularly the laser pipe cutting machine, is transforming how industries approach precision and efficiency. With automation at the helm, businesses can expect not only increased productivity but also enhanced quality in their operations.

The Future of Metal Cutting Technologies

The future of metal cutting technologies is bright and filled with possibilities, primarily driven by innovations in laser technology. As industrial laser cutters become more sophisticated, they promise to deliver unmatched precision and speed in various applications. The evolution towards fully automated systems will further streamline processes, allowing manufacturers to adapt quickly to market demands while minimizing waste.

Selecting the Best Laser Cutting Machine

Choosing the right laser cutting machine can feel like navigating a maze, but understanding your specific needs can simplify this process significantly. Factors such as material type, thickness, and production volume should guide your decision when selecting a metal cutting machine laser that aligns with your operational goals. Whether you opt for a CO2 or fiber laser cutter, ensuring it meets industry standards for efficiency and performance is critical for long-term success.

Partnering with Kiant Machinery for Success

When it comes to investing in advanced manufacturing solutions like a laser pipe cutting machine, partnering with an experienced provider can make all the difference. Kiant Machinery stands out as a leader in this space, offering innovative solutions tailored to meet diverse industry needs while providing exceptional customer support. With their expertise and commitment to quality service, manufacturers can confidently navigate their journey toward automation and efficiency.