Introduction

In today's fast-paced manufacturing landscape, the adoption of advanced technologies is crucial for staying competitive. Among these innovations, fiber laser cutting machines have emerged as a game-changer in precision metal cutting. Understanding the intricacies of fiber laser technology not only enhances operational efficiency but also significantly impacts the overall cost structure associated with acquiring and maintaining these high-tech laser machines.

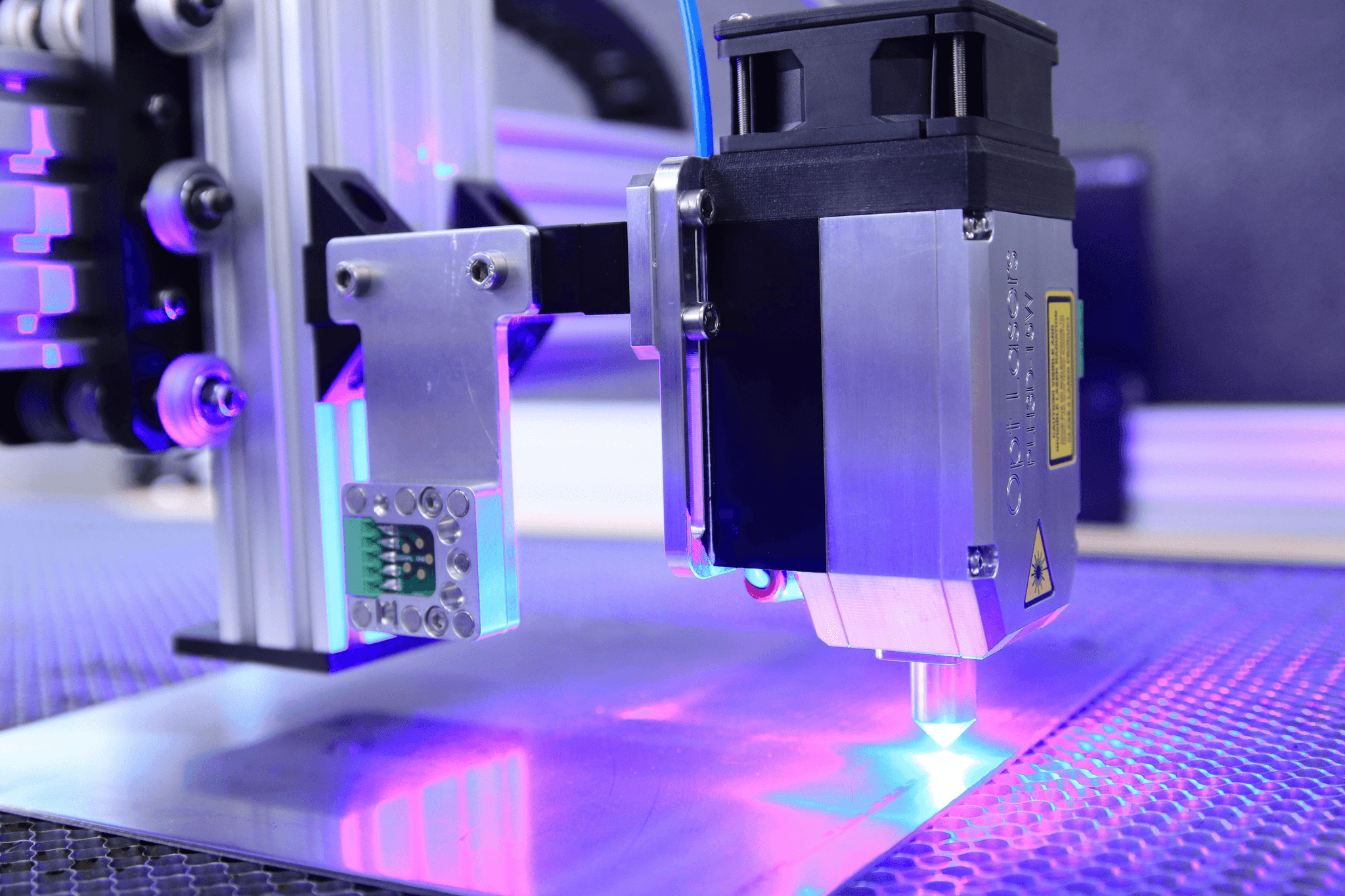

Understanding Fiber Laser Technology

Fiber laser technology utilizes a solid-state laser source to produce highly concentrated beams of light, enabling precise and efficient cutting of various materials, particularly metals. This method has revolutionized the way industries approach metal fabrication, offering greater speed and accuracy compared to traditional cutting methods. With its ability to cut through thicker materials and intricate designs effortlessly, the fiber laser cutting machine has become an indispensable tool in modern manufacturing.

The Importance of Cost Transparency

When considering a significant investment like a fiber laser cutting machine, understanding the price structure is paramount. Cost transparency not only helps buyers make informed decisions but also allows them to evaluate long-term savings and returns on investment more accurately. By breaking down costs associated with equipment purchase, maintenance, and operation, businesses can better navigate their budgetary constraints while maximizing productivity.

Key Factors Influencing Prices

Several factors influence the pricing of fiber laser cutting machines in today’s market landscape. Equipment specifications such as power output, bed size, and additional features play a critical role in determining the overall cost; higher specifications often mean higher prices but can lead to greater efficiency gains over time. Additionally, factors like manufacturer reputation, warranty offerings, and ongoing maintenance costs contribute significantly to the final price tag of any metal cutting laser cutter or related machinery.

Overview of Fiber Laser Cutting Machines

Fiber laser cutting machines are revolutionizing the way industries approach metal fabrication and cutting tasks. Utilizing advanced fiber laser technology, these machines deliver precise cuts with exceptional speed and efficiency. As businesses increasingly seek cost-effective solutions, understanding fiber laser cutting machine price becomes essential for making informed investments.

What is a Fiber Laser Cutting Machine

A fiber laser cutting machine is a type of industrial machinery that uses a high-powered laser beam to cut through various materials, particularly metals. The technology harnesses the power of fiber optics to generate a focused beam that can slice through thick sheets with remarkable accuracy. With the ability to handle complex designs and intricate patterns, these cutting machines have become indispensable in modern manufacturing environments.

Applications in Various Industries

The versatility of fiber laser cutting machines makes them suitable for a wide range of applications across diverse industries. From automotive and aerospace to metalworking and construction, these machines are employed for tasks such as sheet metal fabrication, signage production, and intricate part manufacturing. As industries continue to innovate, the demand for efficient metal cutting laser cutters grows, highlighting the importance of understanding their capabilities.

Benefits Over Traditional Cutting Methods

First and foremost, these machines offer faster processing speeds than conventional options like plasma or water jet cutters—meaning less downtime and more productivity on the shop floor. Additionally, they provide cleaner cuts with minimal heat-affected zones, reducing post-processing requirements while improving overall quality; this ultimately leads to lower operational costs and better returns on investment when considering factors like fiber laser cutting machine price.

Breakdown of Pricing Factors

Equipment Specifications and Features

The specifications and features of a fiber laser cutting machine are crucial in determining its price tag. Machines equipped with higher wattage lasers, advanced cooling systems, and automation capabilities will generally command higher prices than their more basic counterparts. Additionally, features such as programmable controls and enhanced safety mechanisms can also influence the overall cost of metal cutting laser cutters.

Investing in a high-quality laser machine often means considering not just initial costs but also long-term value derived from efficiency gains and precision cuts. A robust model might have a steeper upfront fiber laser cutting machine price but could save you money over time through reduced operational costs and enhanced productivity. Therefore, when evaluating options, it's essential to weigh these specifications against your specific operational needs.

Manufacturer Reputation and Warranty

Another significant factor affecting the price of your cutting machine laser is the reputation of its manufacturer. Well-established brands often charge more for their products because they offer proven reliability, superior customer support, and extensive warranties that cover potential issues down the line. This peace of mind can be invaluable when investing in expensive laser machinery.

A solid warranty not only protects your investment but also signals that a manufacturer stands behind their product's quality—an assurance that lesser-known brands might not provide at all. When comparing different fiber laser cutting machines on the market, consider how much weight you place on brand reputation versus features; it may lead you to reconsider that seemingly cheaper option after all!

Maintenance and Operating Costs

Lastly, don’t overlook maintenance and operating costs when assessing fiber laser cutting machine prices; they can add up quickly if you're not careful! Routine maintenance is essential for keeping your metal cutting laser cutter running smoothly over time—think scheduled inspections or replacing worn parts—but some models require more upkeep than others due to design complexity or component quality.

Additionally, consider energy consumption rates since more efficient machines will help lower ongoing operational expenses significantly over their lifespan. So while one model may seem cheaper initially based on its sticker price alone, those hidden costs could turn it into an expensive choice in practice! Always factor in these ongoing expenses alongside purchase costs to get an accurate picture of what you'll truly be spending on your new laser machinery.

Current Market Landscape

The landscape of fiber laser cutting machines is a dynamic one, influenced by various manufacturers, technological advancements, and market demands. As industries increasingly adopt these cutting-edge tools for their efficiency and precision, understanding the competitive arena becomes essential. In this section, we’ll explore how different brands stack up against each other and what sets Kiant Machinery apart in the realm of laser machinery.

Comparison of Popular Brands

When it comes to fiber laser cutting machine prices, several brands are prominent players in the market. Companies like Trumpf, Bystronic, and Amada have established themselves with robust reputations for quality and performance. However, while their metal cutting laser cutters are often seen as the gold standard, they come with hefty price tags that can make them less accessible for smaller businesses looking to invest in a cutting machine laser.

In contrast to these industry giants, emerging brands have begun to offer competitive alternatives at more attractive price points without sacrificing quality. For instance, some newer entrants focus on providing advanced features at lower costs, appealing to budget-conscious buyers who still want high-performance equipment. This diversification in options means that potential buyers must carefully evaluate not just the initial purchase price but also long-term operational costs associated with each brand's offering.

Ultimately, choosing the right fiber laser cutting machine involves weighing various factors beyond just brand reputation or initial cost—such as after-sales support and warranty options—which can significantly impact overall satisfaction and productivity over time.

How Kiant Machinery Stands Out

Kiant Machinery has carved a niche for itself within this crowded marketplace by prioritizing both affordability and innovation in its offerings. Their fiber laser cutting machines boast impressive specifications that rival those of more established brands but at a fraction of the typical metal cutting laser cutter price. This commitment to delivering value ensures that customers receive reliable equipment without breaking the bank.

Moreover, Kiant Machinery excels in customer support and service post-purchase—a crucial factor for companies investing in a cutting machine laser. Their proactive approach includes training programs for operators and readily available technical assistance when needed. Such dedication not only enhances user experience but also contributes to minimizing downtime—a significant concern when operating any type of laser machinery.

In addition to their competitive pricing strategy on fiber laser cutting machines, Kiant is continually investing in research and development to stay ahead of industry trends. This forward-thinking mindset allows them to adapt quickly to changing market demands while ensuring their products remain state-of-the-art.

Global Trends Affecting Prices

The global landscape for fiber laser cutting machines is shaped by several macroeconomic trends that influence pricing structures across different regions. One significant factor is supply chain dynamics; disruptions caused by geopolitical tensions or natural disasters can lead to increased costs for raw materials used in manufacturing lasers—ultimately impacting the final price consumers pay for equipment like metal cutting lasers.

Additionally, advancements in technology play a pivotal role in shaping prices within this sector. As manufacturers develop more efficient production methods or incorporate new technologies into their designs (like automation), these innovations tend to lower production costs over time—potentially leading to reduced prices for consumers purchasing new equipment such as a fiber laser cutting machine.

Lastly, fluctuating demand across various industries also affects pricing strategies among manufacturers; during economic booms or shifts toward automation trends (especially post-pandemic), there may be an uptick in orders which could drive prices higher due to increased competition among buyers vying for limited supplies of high-quality machinery.

Case Studies on Investment Returns

When it comes to investing in a fiber laser cutting machine, understanding the potential returns can be a game-changer. Numerous companies have made the leap into laser technology and experienced significant cost savings and efficiency gains. These case studies illustrate how businesses have optimized their operations through smart investments in metal cutting laser cutters.

Real-World Examples of Cost Savings

Consider a mid-sized metal fabrication company that invested in a state-of-the-art fiber laser cutting machine. Initially, they were hesitant due to the fiber laser cutting machine price, but after just one year of operation, they reported a 30% reduction in material waste compared to their previous processes. This translates into substantial savings on raw materials and labor costs, showcasing that while the upfront investment might seem steep, the long-term financial benefits are undeniable.

Another example is an automotive parts manufacturer that switched from traditional cutting methods to a cutting machine laser system. They found that not only did their production speed double, but they also saved over $100,000 annually by reducing operational costs associated with downtime and inefficiencies. Such real-world cases highlight how investing in advanced laser machinery can lead to impressive cost reductions.

Efficiency Gains with Fiber Laser Cutting

The efficiency gains from using a fiber laser cutting machine are hard to overlook. One notable case involved an aerospace component manufacturer who transitioned from conventional methods to a high-speed laser cutter. They achieved faster turnaround times on complex parts, allowing them to take on more projects without increasing labor costs—a clear win for both productivity and profitability.

Moreover, companies leveraging these machines often report improved precision and quality in their cuts compared to older technologies. For instance, a furniture design firm noted that utilizing a metal cutting laser cutter not only enhanced their design capabilities but also minimized post-production adjustments by 40%. With such efficiency improvements at play, it’s no wonder many businesses are eager to embrace this technology.

Long-Term Value of Laser Machinery

Investing in fiber laser technology is not just about immediate cost savings; it's also about long-term value creation for your business. A prominent electronics manufacturer demonstrated this when they opted for an advanced fiber laser system over traditional options due to its superior longevity and lower maintenance requirements—factors that contribute significantly to overall equipment effectiveness (OEE).

In addition, as industries evolve and demand for precision manufacturing grows, companies equipped with reliable cutting machines will find themselves ahead of the competition—able to adapt swiftly without incurring hefty retooling expenses or delays. The initial investment may be noteworthy when considering the fiber laser cutting machine price; however, this decision pays off handsomely as businesses benefit from increased market share and sustained growth over time.

Navigating the Purchase Process

Purchasing a fiber laser cutting machine can feel like navigating a labyrinth, but with the right approach, you can find your way to an optimal choice. Understanding what to look for in a cutting machine laser will save you time and money in the long run. It’s essential to consider not only the initial fiber laser cutting machine price but also how it aligns with your production needs and budget.

Tips for Selecting the Right Cutting Machine

Selecting the right metal cutting laser cutter involves evaluating various factors that cater to your specific requirements. First, assess your material types and thicknesses; different machines excel in different applications, so knowing what you'll cut is crucial. Additionally, consider features like power output, speed, and automation capabilities—these can significantly impact both performance and efficiency.

Another tip is to look into user reviews and testimonials about specific models; this can provide insights into reliability and ease of use that specifications alone may not reveal. Don’t forget to factor in future scalability as well; choosing a cutting machine laser that can grow with your business ensures you won’t be back at square one in just a few years. Finally, always compare multiple vendors before making a decision; this gives you leverage when negotiating the ultimate fiber laser cutting machine price.

Understanding Fiber Laser Cutting Machine Price Quotes

Quotes should break down costs into categories such as equipment specifications, installation fees, and additional accessories or software needed for operation. If a quote seems vague or lacks detail, don’t hesitate to ask for clarification—after all, transparency is essential when investing in expensive equipment like laser machinery.

Keep an eye out for hidden costs as well; maintenance agreements or training sessions often come at an extra fee that might not be included upfront. Also remember that while lower prices might seem enticing initially, they could lead to higher operational costs down the line if quality is sacrificed for savings on the purchase price of your metal cutting laser cutter. A thorough understanding of these quotes will empower you to make informed decisions without falling victim to unexpected expenses.

Importance of After-Sales Support

After-sales support can make or break your experience with any piece of machinery—including your new fiber laser cutting machine. Once you've made your purchase decision based on competitive pricing and features, ensure that robust after-sales services are part of the package deal; this includes installation support and ongoing maintenance options tailored specifically for your model of laser machinery.

Good after-sales support means quick responses when issues arise and access to parts when repairs are necessary—both critical elements that keep production running smoothly without costly downtime due to equipment failure. Furthermore, reliable customer service often indicates manufacturer reputation; companies known for their commitment post-purchase typically provide better overall value than those who disappear after they’ve sealed the deal.

Conclusion

In the ever-evolving landscape of manufacturing, understanding the nuances of fiber laser cutting machine price is crucial for businesses looking to invest wisely. The future promises to bring more advanced technologies and competitive pricing, making it an exciting time for those in need of a metal cutting laser cutter. Staying informed about these trends can help you navigate the market effectively.

Future Trends in Laser Machine Pricing

As technology continues to advance, we can expect fiber laser cutting machine prices to become more accessible. Innovations in efficiency and production processes will likely lead to reduced costs, making high-quality laser machinery available for a broader range of industries. This shift means that businesses previously unable to afford such equipment may soon find themselves equipped with state-of-the-art cutting machine lasers at a fraction of the cost.

Making Informed Purchasing Decisions

When it comes time to invest in a fiber laser cutting machine, knowledge is power. Understanding what affects the laser machine price—such as specifications, manufacturer reputation, and warranty options—can significantly impact your purchasing decision. By doing thorough research and comparing different models and brands, you can ensure that you choose a metal cutting laser cutter that aligns with both your budget and operational needs.

The Role of Technology in Cost Reduction

Technology plays a pivotal role in reducing costs associated with operating a fiber laser cutting machine. Advanced features like automated controls and improved energy efficiency not only enhance performance but also lower long-term expenses related to maintenance and operation. As manufacturers continue to innovate, businesses can expect even greater savings while boosting productivity through modernized laser machinery.