Introduction

In the ever-evolving landscape of construction, light gauge steel frames (LGSF) have emerged as a game-changer. These innovative structures not only provide robust support but also offer unparalleled flexibility and efficiency in the building process. As we delve into the world of light gauge steel structures, it becomes evident that they are revolutionizing how metal construction companies approach projects.

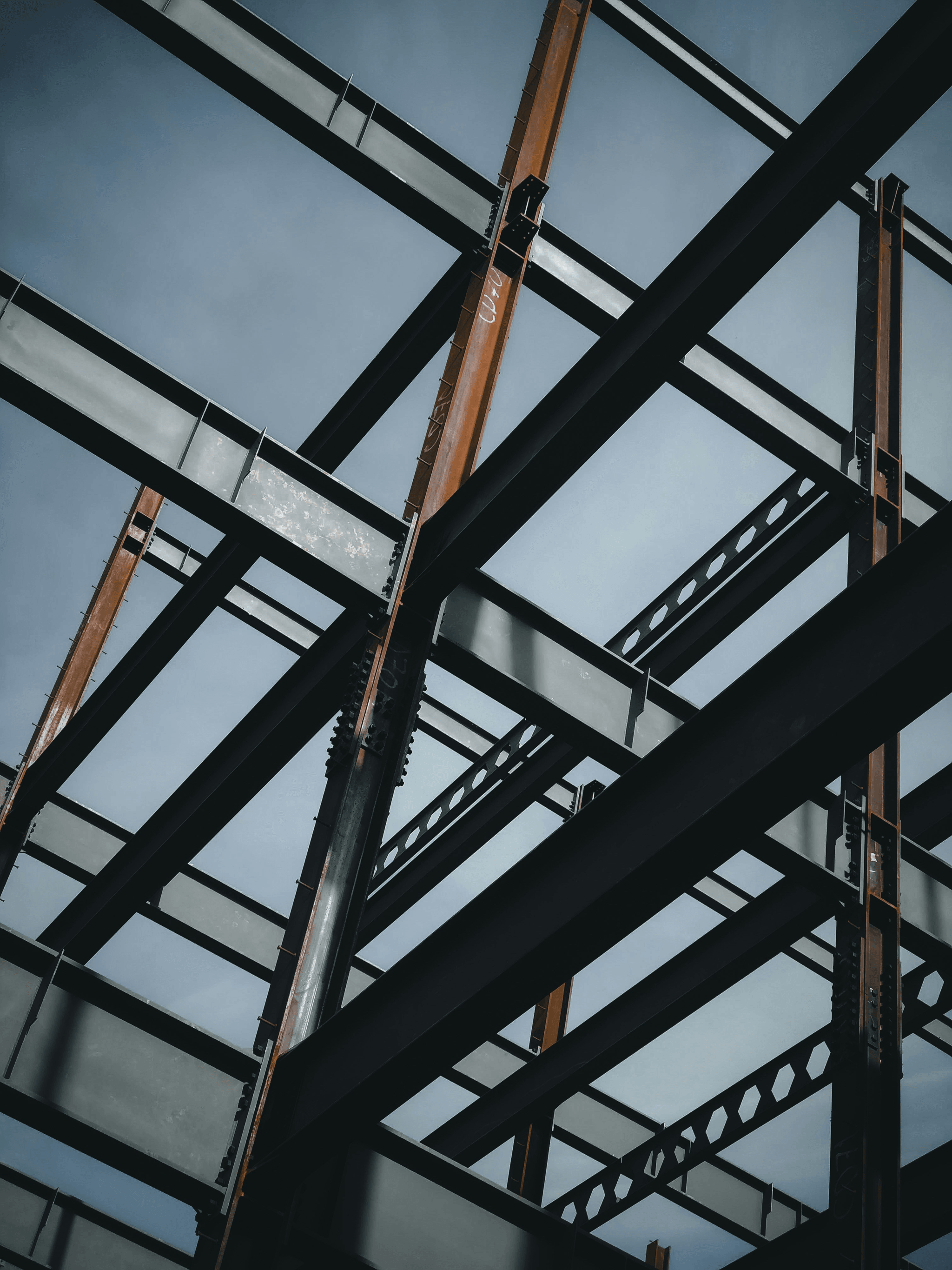

Understanding Light Gauge Steel Frames

A light gauge steel structure is built using thin sheets of steel that are cold-formed into various shapes and sizes, allowing for lightweight yet durable constructions. This method contrasts sharply with traditional building materials like wood or concrete, which can be heavier and less sustainable. The versatility of LGSF makes it an attractive option for both residential and commercial applications, paving the way for more innovative designs in steel building construction.

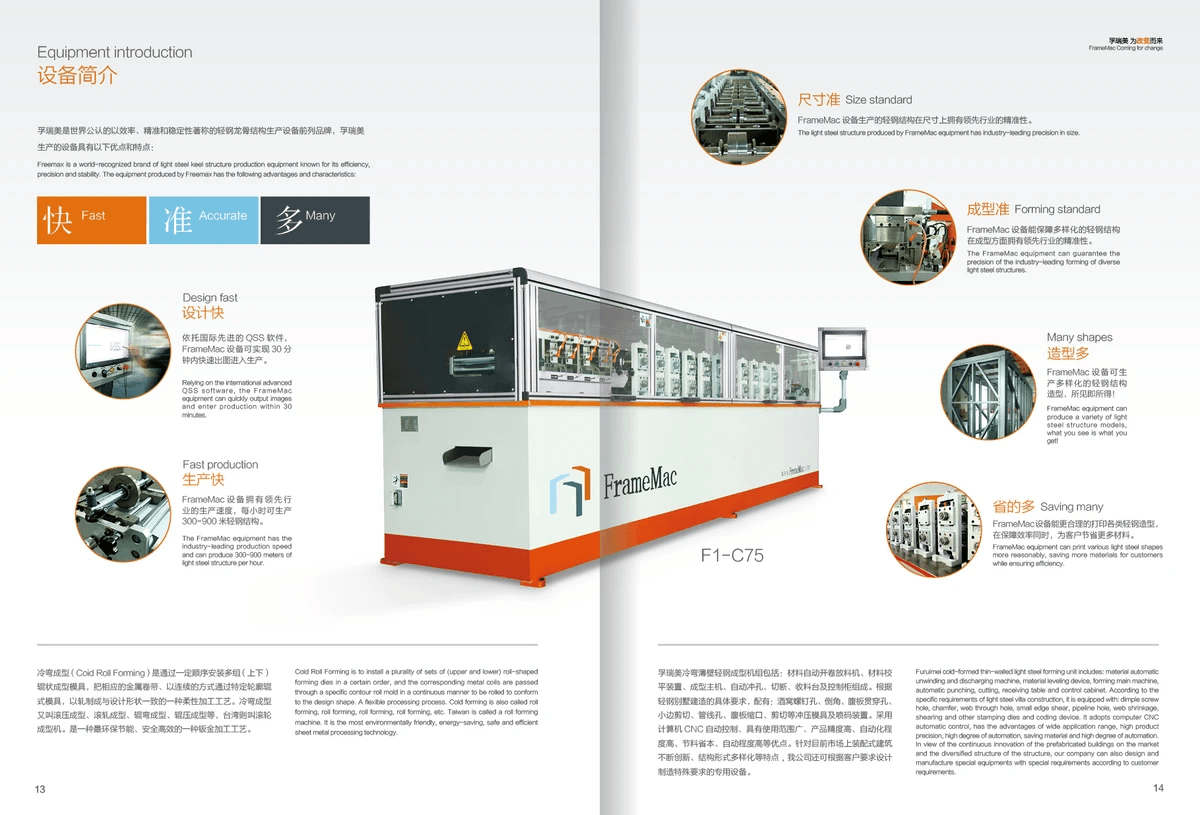

The Role of LGSF Machines in Construction

LGSF machines play a pivotal role in streamlining the production process for steel construction companies by automating fabrication tasks with precision and speed. These machines enable manufacturers to produce high-quality components that fit together seamlessly on-site, significantly reducing labor costs and construction time. In a market where efficiency is paramount, investing in advanced LGSF machinery can set a steel construction company apart from its competitors.

Benefits of Steel Structures in Building

Steel structures offer numerous advantages over traditional materials; they are not only stronger but also resistant to pests, rot, and extreme weather conditions. Moreover, light gauge steel frames contribute to sustainability efforts by allowing for recycling and reducing waste during the building process. As more architects and builders recognize these benefits, the demand for steel building homes continues to rise across various industries.

What is Light Gauge Steel Frame Construction?

Light gauge steel frame construction (LGSF) is an innovative approach to building that utilizes thin sheets of steel to create a strong and durable framework for various structures. This method has gained traction in the construction industry due to its lightweight characteristics and exceptional strength-to-weight ratio. As a result, metal construction companies are increasingly adopting light gauge steel structures for residential, commercial, and industrial applications.

Defining Light Gauge Steel Structure

A light gauge steel structure consists of cold-formed steel sections that are manufactured into various shapes and sizes, allowing for flexibility in design and application. These sections are typically less than 3mm thick, making them lightweight yet robust enough to withstand significant loads. The precision manufacturing process ensures that each component fits together seamlessly during the assembly phase of steel building construction.

Advantages Over Traditional Materials

One of the standout advantages of light gauge steel structure over traditional materials like wood or concrete is its superior strength combined with reduced weight. This not only leads to lower transportation costs but also allows for quicker assembly on-site, reducing overall labor expenses in the long run. Additionally, LGSF is resistant to pests, rot, and fire, making it a more durable choice compared to conventional materials used in steel construction.

Applications in Various Industries

Light gauge steel frame construction finds applications across numerous industries due to its versatility and adaptability. From residential projects such as steel building homes to large-scale commercial developments like warehouses or office buildings, LGSF can cater to diverse needs within the realm of metal construction companies. Moreover, sectors such as healthcare and education have also embraced this technology for constructing clinics and schools efficiently while maintaining high standards of safety and durability.

Key Features of LGSF Machines

Light Gauge Steel Frame (LGSF) machines are revolutionizing the way we think about steel construction. These machines are engineered to enhance the efficiency and precision of building with light gauge steel structures, making them an essential asset for metal construction companies. By understanding their key features, we can appreciate how they contribute to modern steel building construction.

Precision in Steel Fabrication

One of the standout features of LGSF machines is their ability to deliver precision in steel fabrication. This level of accuracy ensures that every component fits perfectly within a light gauge steel structure, minimizing waste and maximizing structural integrity. For steel construction companies, this means fewer errors during assembly and a reduction in costly rework, which ultimately leads to higher quality steel building homes.

Moreover, precision in fabrication allows for intricate designs that were once challenging to achieve with traditional materials. The exactness provided by these machines enables architects and builders to push the boundaries of creativity while maintaining safety standards in their projects. In an industry where every millimeter counts, LGSF machines set a new standard for what is possible in metal construction.

Automation and Efficiency in Production

Automation is another key feature that sets LGSF machines apart from traditional methods of steel building construction. With advanced technology integrated into these machines, production lines can operate at unprecedented speeds while maintaining high levels of accuracy. This efficiency not only accelerates project timelines but also reduces labor costs associated with manual fabrication processes.

Additionally, automated systems minimize human error, ensuring that each piece produced adheres to stringent quality standards required for robust steel structures. This streamlined approach allows metal construction companies to scale operations without sacrificing quality or safety—essential factors when competing in today’s fast-paced market for steel buildings. Ultimately, automation transforms how we approach production in the realm of steel and construction.

Versatility for Different Steel Construction Needs

Versatility is crucial when selecting machinery for light gauge steel structure projects; LGSF machines excel in this regard by accommodating various design specifications and applications across industries. Whether it’s residential homes or commercial buildings, these machines can adapt to meet diverse architectural requirements without compromising on performance or structural integrity.

Their ability to handle multiple tasks—from cutting and bending to assembling components—makes them invaluable tools for any steel construction company looking to diversify its offerings or tackle unique projects efficiently. As the demand grows for innovative solutions within metal construction companies, having versatile machinery becomes a competitive advantage that can lead to increased profitability and customer satisfaction.

Choosing the Right LGSF Machine Manufacturer

Selecting the right manufacturer for your light gauge steel structure is pivotal to the success of any steel building construction project. Quality in steel construction directly influences durability, safety, and overall performance of the final product. With many metal construction companies vying for attention, it’s essential to identify a partner that meets rigorous standards.

Importance of Quality in Steel Construction

When it comes to steel construction, quality is non-negotiable. A well-constructed light gauge steel structure can withstand environmental stresses better than traditional materials, making it a preferred choice for modern buildings. Poor-quality materials can lead to structural failures and costly repairs down the line; hence, investing in high-quality machines is crucial for any serious steel construction company.

Moreover, high-quality machinery ensures precision in every fabrication process, which is vital when constructing intricate designs or large-scale projects like steel building homes. The integrity of your entire project hinges on the quality of both materials and machinery used during production. Therefore, choosing a reputable LGSF machine manufacturer should be at the forefront of your decision-making process.

Why Kiant Machinery Stands Out

Kiant Machinery has carved a niche for itself among metal construction companies due to its unwavering commitment to quality and innovation in light gauge steel structures. Their machines are designed with cutting-edge technology that enhances efficiency while maintaining precision—two critical factors in successful steel building construction. With years of experience under their belt, Kiant Machinery has built a reputation as a reliable partner for various types of projects across industries.

What sets Kiant apart from other manufacturers is their focus on customization; they understand that each project may have unique requirements and offer tailored solutions accordingly. Additionally, their machines are user-friendly and integrate seamlessly into existing production lines without causing disruptions—an essential feature for busy steel construction companies aiming to maximize productivity without sacrificing quality.

Customer Support and After-Sales Services

A great manufacturing company doesn’t just sell machines; they provide ongoing support that ensures your investment pays off long-term. Kiant Machinery excels in customer support by offering comprehensive training programs and resources aimed at helping clients operate their LGSF machines effectively from day one. This commitment extends beyond installation; they also offer robust after-sales services that include maintenance checks and quick response times should issues arise.

In an industry where downtime can be costly, having access to reliable customer support makes all the difference when operating light gauge steel structures efficiently. Kiant understands this need and prioritizes building lasting relationships with clients through exceptional service practices that set them apart from competitors in the market landscape.

The Process of Steel Building Construction

Building with light gauge steel structures is an intricate dance of design, production, and execution. Understanding each step in the process ensures that your steel building construction is efficient and meets all necessary standards. From initial design to final assembly, every phase plays a crucial role in the overall success of your project.

Steps in Designing a Steel Structure

The first step in designing a light gauge steel structure involves conceptualizing the architectural design while ensuring it adheres to local building codes and regulations. Architects collaborate closely with engineers to create blueprints that optimize both functionality and aesthetics, taking into account load-bearing requirements and spatial considerations. Once the initial designs are approved, detailed structural calculations are performed to ensure that the proposed steel construction can withstand environmental stresses like wind and seismic activity.

Next comes selecting the right materials for your project; this is where metal construction companies shine by providing high-quality light gauge steel options tailored for specific applications. The choice of materials directly impacts not only durability but also cost-effectiveness over time, making it essential for any steel construction company to prioritize quality in their offerings. Finally, creating detailed shop drawings allows manufacturers to prepare for fabrication accurately, ensuring that every element fits together seamlessly during assembly.

Integrating LGSF Machines in Production

Once the design phase is complete, integrating LGSF machines into production becomes vital for efficiency and precision during fabrication. These machines automate many processes involved in cutting and shaping light gauge steel components, significantly reducing labor costs while increasing output speed—an absolute win-win for any steel building construction project! Furthermore, modern LGSF machines offer advanced features such as CNC (Computer Numerical Control) technology that ensures every piece meets exact specifications without room for error.

This automation not only streamlines production but also enhances flexibility; manufacturers can quickly adapt their processes to accommodate various designs or changes requested by clients without compromising quality or timelines. Additionally, integrating LGSF machines allows metal construction companies to scale operations efficiently—whether they're working on small residential projects or large commercial buildings requiring substantial quantities of materials. Ultimately, leveraging these advanced technologies leads to faster turnaround times and improved overall project management.

Best Practices for Steel Building Homes

When constructing steel building homes using light gauge steel structures, adhering to best practices can make all the difference between success and setbacks. First off, proper planning cannot be overstated; engaging experienced professionals from both design and engineering teams early on will help avoid costly modifications later in the process. Furthermore, utilizing high-quality materials throughout ensures structural integrity while providing lasting value—a must-have when investing in any type of steel construction.

Another best practice involves regular inspections during various stages of the build; this helps identify potential issues before they escalate into more significant problems down the line. Metal construction companies should have established protocols for quality assurance checks at each step—from material selection through final assembly—to maintain high standards throughout every project phase. Lastly, educating homeowners about maintenance needs specific to their new light gauge steel structure will empower them with knowledge about preserving their investment long-term.

Future Trends in Metal Construction

The landscape of metal construction is rapidly evolving, driven by innovations and a growing emphasis on sustainability. Light gauge steel structures are becoming increasingly popular due to their adaptability and strength, making them a preferred choice for various building applications. As we look ahead, the integration of advanced technologies and eco-friendly practices will shape the future of steel building construction.

Innovations in Light Gauge Steel Technology

Innovative technologies are transforming light gauge steel structures into more efficient and versatile building solutions. Advanced design software enables precise modeling, which enhances the accuracy of steel fabrication and minimizes waste in production. Additionally, automation in manufacturing processes allows metal construction companies to produce high-quality materials at an unprecedented speed, leading to shorter project timelines for steel building homes.

Moreover, developments such as cold-formed steel technology are enhancing the structural integrity of light gauge steel frames while reducing material costs. This means that builders can achieve robust designs without compromising on weight or flexibility. As a result, more architects and builders are turning to these innovative solutions offered by reputable steel construction companies for their next projects.

Sustainability in Steel Construction

Sustainability is no longer just a buzzword; it’s becoming integral to modern steel construction practices. Light gauge steel structures are inherently recyclable, which makes them an environmentally friendly choice compared to traditional materials like wood or concrete. This aspect not only reduces landfill waste but also lowers the carbon footprint associated with new builds.

Furthermore, many metal construction companies are now focusing on sustainable sourcing of materials and energy-efficient manufacturing processes. By utilizing renewable energy sources during production and promoting recycling initiatives within their operations, these companies contribute significantly to reducing environmental impact in the industry. The growing demand for sustainable practices is pushing more stakeholders in the steel building sector to adopt eco-friendly methods.

The Growing Market for Steel Buildings

The market for light gauge steel structures is witnessing significant growth as industries recognize their advantages over traditional building methods. With rising urbanization and population density, there’s an increasing need for durable yet affordable housing solutions like steel building homes that can be erected quickly without sacrificing quality or aesthetics.

Additionally, sectors such as commercial real estate are embracing the benefits of using light gauge steel frames due to their cost-effectiveness and design flexibility compared to conventional materials. As more developers seek reliable options from established steel construction companies, we can expect continued expansion in the use of metal buildings across various applications—from residential units to large-scale commercial projects.

Conclusion

In the ever-evolving landscape of construction, light gauge steel structures are carving out a prominent niche. With their myriad advantages, including durability and design flexibility, these structures are becoming the go-to choice for modern building projects. As we look to the future, the prospects for light gauge steel buildings appear brighter than ever, making them an indispensable part of steel construction.

Prospects for Light Gauge Steel Structures

The future of light gauge steel structures is promising, particularly as sustainability becomes a focal point in construction practices. These steel building homes not only offer energy efficiency but also reduce waste during production and assembly, aligning perfectly with green building initiatives. Moreover, with advancements in technology and design capabilities, metal construction companies are poised to explore new markets and applications for these innovative structures.

Why Invest in LGSF Machines?

Investing in LGSF machines is a strategic move for any steel construction company looking to enhance productivity and quality. These machines enable precision fabrication that significantly reduces material waste while ensuring that every component fits perfectly during assembly—a critical factor in successful steel building construction. Furthermore, automating processes through advanced LGSF machines allows companies to scale operations efficiently without compromising on quality or turnaround times.

The Importance of Partnering with Experts

When it comes to navigating the complexities of steel and construction projects, partnering with experts is essential for success. Experienced professionals can provide invaluable insights into selecting the right materials and technologies for your specific needs—ensuring that your investment in light gauge steel structures pays off handsomely over time. Additionally, collaborating with knowledgeable metal construction companies can help streamline processes from design to execution, ultimately leading to superior outcomes in your projects.