Introduction

In recent years, light gauge steel framing has emerged as a popular choice in construction, offering durability and flexibility that traditional materials often lack. This rise can be attributed to advancements in manufacturing processes, particularly the efficiency of roll forming machines. As the demand for affordable solutions grows, understanding the role of these machines becomes essential for manufacturers looking to stay competitive.

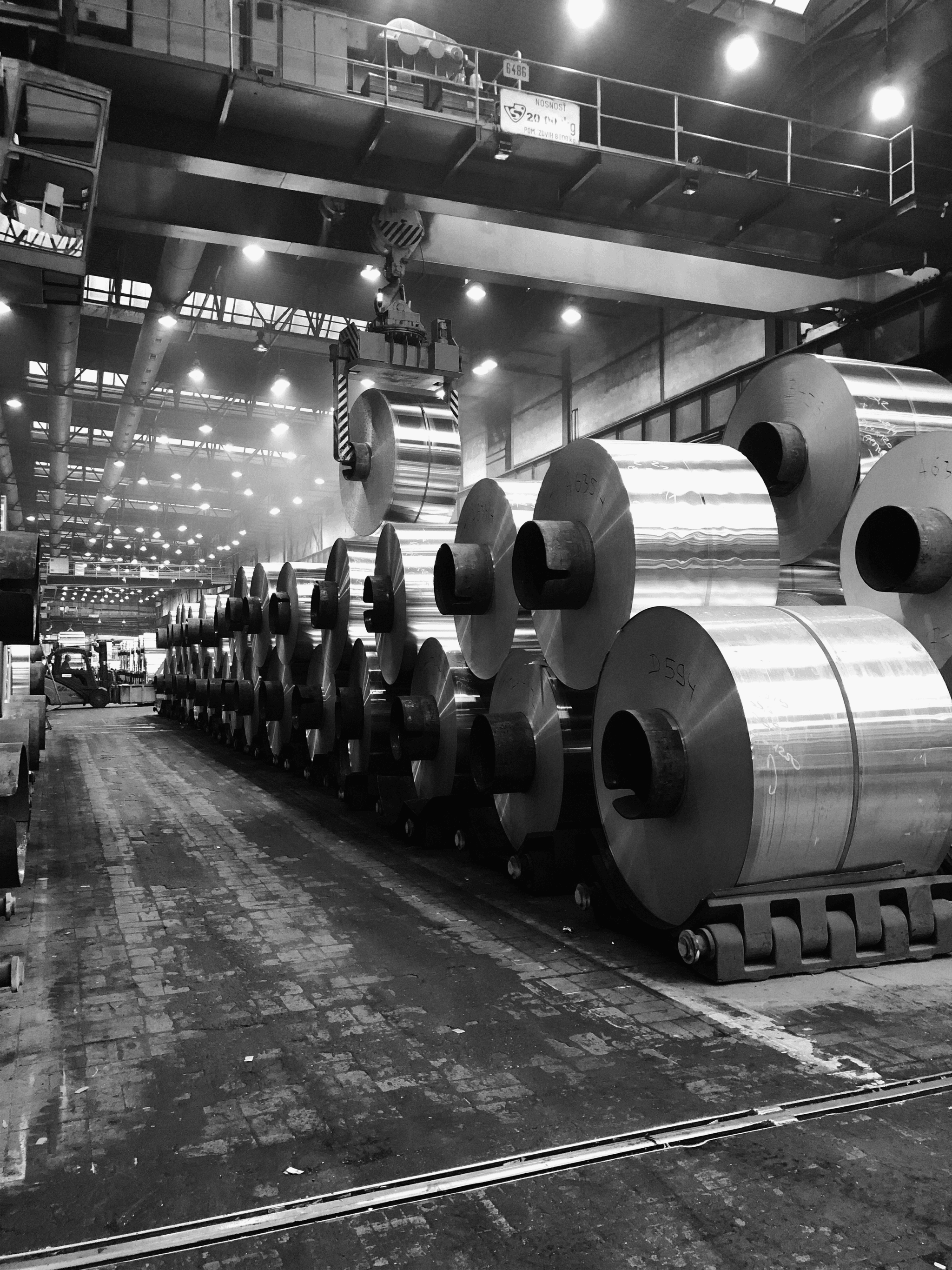

The Rise of Light Gauge Steel Framing

Light gauge steel framing has revolutionized the construction industry by providing a lightweight yet sturdy alternative to wood and concrete. Architects and builders are increasingly turning to this method due to its cost-effectiveness and sustainability benefits. With a surge in projects requiring rapid completion times, the need for efficient production methods like those offered by roll forming machine manufacturers is more critical than ever.

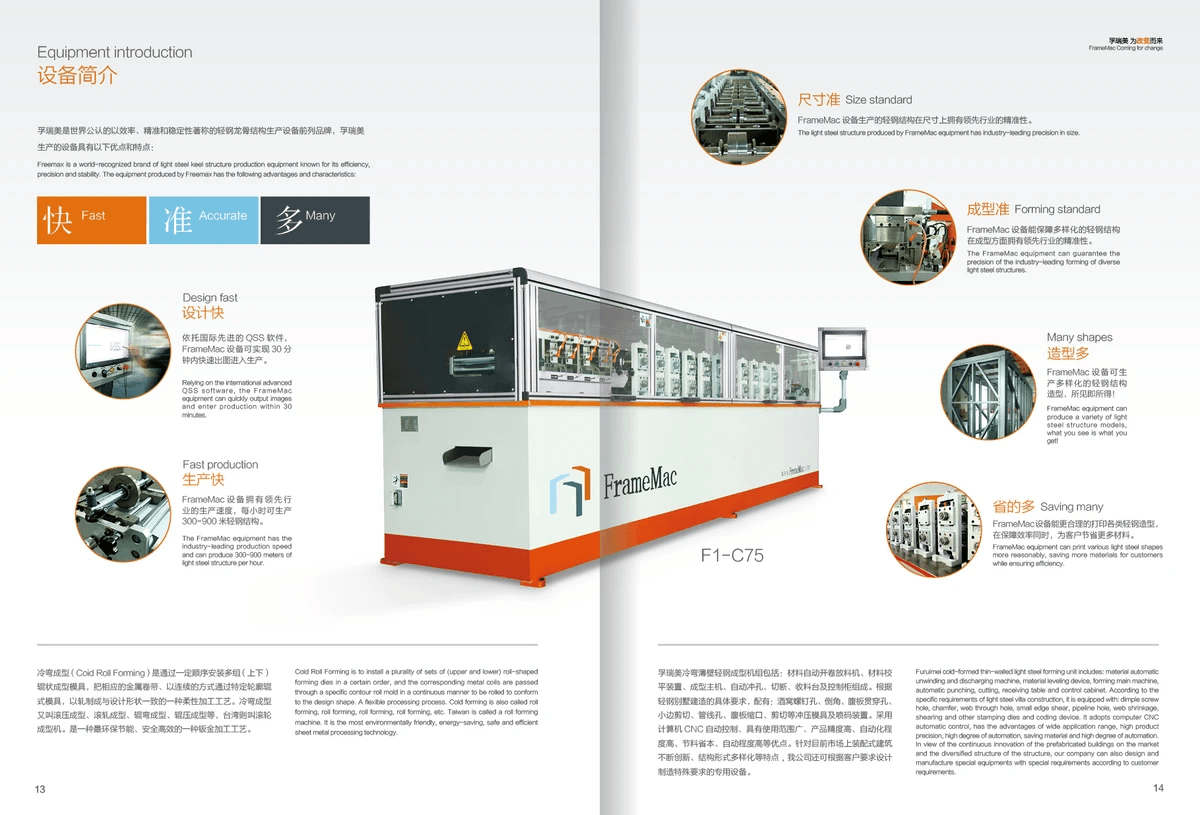

Understanding Roll Forming Machines

At the heart of producing light gauge steel components are roll forming machines, which create uniform shapes from metal sheets through continuous bending processes. These machines are designed with precision engineering to ensure high-quality output while minimizing waste material. Familiarizing oneself with the capabilities of sheet metal forming machines not only enhances production efficiency but also opens doors to innovative design possibilities.

Why Choose Affordable Solutions

Choosing affordable solutions is imperative for businesses aiming to maximize their profit margins without compromising quality. By investing in cost-effective machinery like sheet metal roll forming machines, manufacturers can significantly reduce operational costs while maintaining high standards of production. Additionally, exploring various roll forming machine manufacturers allows companies to find reliable equipment that meets their specific needs without breaking the bank.

The Basics of Roll Forming Machines

Roll forming machines are pivotal in modern manufacturing, especially in the realm of light gauge steel framing. These machines transform flat metal sheets into various shapes and profiles through a continuous bending process, making them essential for construction and industrial applications. With an array of roll forming machine manufacturers available, finding the right equipment can significantly enhance efficiency and productivity.

What is a Roll Forming Machine

A roll forming machine is a specialized piece of equipment designed to create long lengths of metal profiles by continuously feeding flat sheets through a series of rollers. Each roller progressively bends the sheet into the desired shape, ensuring uniformity and precision throughout the process. This method is particularly effective for producing components used in construction, automotive parts, and other industries where consistent quality is paramount.

Key Components of the Machine

Understanding the key components of a roll forming machine helps in appreciating its functionality. The primary elements include the feed mechanism, which guides the metal sheet; a series of rollers that shape it; and cutting tools that trim it to length once formed. Additionally, many modern machines incorporate advanced control systems to monitor speed and tension, enhancing overall performance—something that sets leading metal machinery suppliers apart from others.

Benefits of Using a Roll Forming Machine

The benefits of using a roll forming machine are numerous and can greatly impact production efficiency. First off, these machines allow for high-speed production with minimal waste since they utilize nearly all material during shaping—a significant cost-saving factor for manufacturers looking for affordable solutions. Furthermore, their ability to produce complex shapes consistently makes them indispensable in industries relying on sheet metal rolling machines for structural integrity and aesthetic appeal.

Affordable Light Gauge Steel Framing Solutions

Light gauge steel framing presents an innovative and cost-effective alternative to traditional building materials. As the demand for affordable construction solutions grows, roll forming machine manufacturers are stepping up to provide efficient and reliable machinery that caters to this need. With a variety of sheet metal forming machines available on the market, finding the right option can significantly impact overall project costs.

Exploring Cost-Effective Options

When considering affordable light gauge steel framing solutions, it’s essential to explore various options that fit within budget constraints without sacrificing quality. Roll forming machines are crucial in producing consistent and precise steel components at lower production costs compared to traditional methods. By utilizing a sheet metal rolling machine, manufacturers can achieve higher efficiency and reduced waste, ultimately leading to significant savings over time.

Moreover, many roll forming machine manufacturers offer entry-level models designed specifically for small businesses or startups looking to enter the market without hefty investments. These cost-effective machines still deliver impressive performance and durability, making them ideal for those venturing into steel framing projects on a budget. As you explore these options, consider how investing in a quality metal machinery supplier can ensure you get the best value for your money.

Comparing Different Manufacturers

With numerous roll forming machine manufacturers in the industry today, comparing their offerings is vital in making an informed decision about your investment. Look for companies that specialize in sheet metal roll forming machines with proven track records of reliability and customer satisfaction. Evaluating factors such as warranty coverage, customer support services, and user reviews can help you identify which suppliers stand out from the crowd.

Additionally, consider how each manufacturer’s equipment aligns with your specific needs regarding production capacity and material specifications. Some manufacturers focus on niche markets with specialized designs while others may offer more versatile solutions adaptable across various applications—this flexibility could be essential depending on your business model. Ultimately, thorough research will help you find a roll forming machine that not only meets your requirements but also enhances productivity at an affordable price point.

How Kiant Machinery Stands Out

Kiant Machinery distinguishes itself among other roll forming machine manufacturers by providing exceptional value through innovative technology and customer-centric service offerings. They have developed a range of advanced sheet metal forming machines tailored to meet diverse industry needs while maintaining competitive pricing structures—a win-win situation for budget-conscious buyers! Moreover, their commitment to after-sales support ensures clients receive ongoing assistance even after purchase.

What sets Kiant Machinery apart further is their dedication to continuous improvement; they consistently integrate feedback from users into their design process for future models—this responsiveness fosters trust among clients who know they’re investing in cutting-edge equipment built around real-world applications. For those searching for a reliable metal machinery supplier offering both affordability and quality assurance, Kiant Machinery is definitely worth considering when looking for a roll forming machine for sale.

The Role of Sheet Metal Forming Machines

Sheet metal forming machines have become indispensable in modern construction projects, revolutionizing how structures are built. These machines, including various types of roll forming machines, enhance efficiency and precision, ensuring that components are fabricated to exact specifications. The importance of these tools cannot be overstated; they streamline production processes and significantly reduce labor costs.

Importance in Construction Projects

In the realm of construction, sheet metal forming machines play a pivotal role by providing essential components for buildings and infrastructure. Roll forming machine manufacturers produce equipment that creates strong, lightweight materials ideal for framing and roofing systems. By utilizing a sheet metal rolling machine, builders can achieve faster project timelines while maintaining high-quality standards.

Moreover, the adaptability of these machines allows them to cater to various design requirements. With options like custom profiles available from leading metal machinery suppliers, construction teams can easily obtain the specific shapes needed for their projects. This versatility not only enhances structural integrity but also promotes innovative architectural designs.

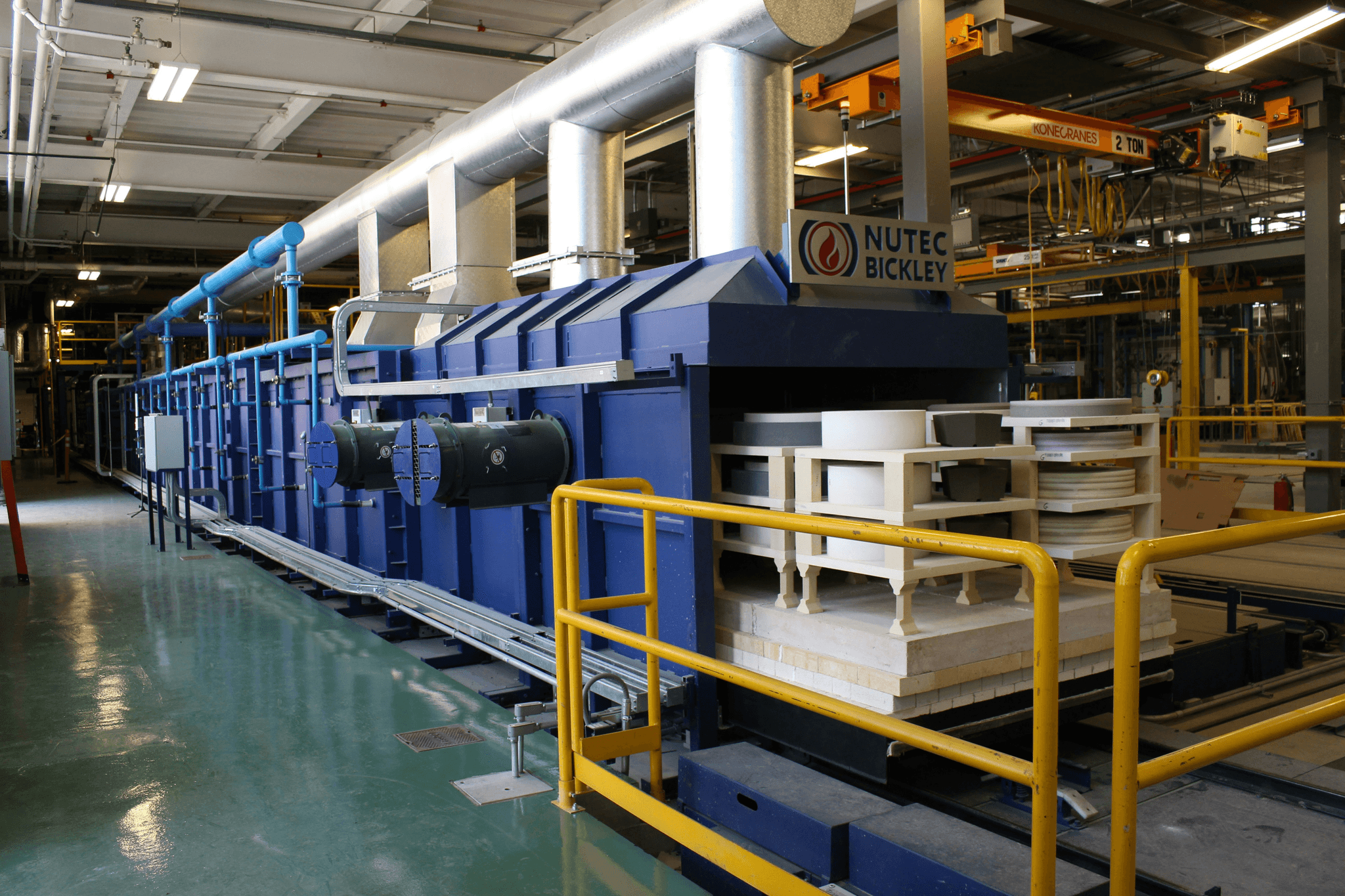

Applications in Various Industries

The applications of sheet metal forming machines extend far beyond construction; they find utility across numerous industries such as automotive, aerospace, and appliance manufacturing. In these sectors, roll forming machines create components ranging from vehicle chassis to intricate parts used in aircraft assembly. The efficiency provided by these specialized tools is unmatched when compared to traditional manufacturing methods.

Additionally, industries that require high-volume production benefit significantly from the speed and consistency offered by sheet metal roll forming machines. For example, manufacturers can produce thousands of identical parts quickly without sacrificing quality or precision. This capability makes them an essential asset for any operation looking to optimize its production line.

Advantages Over Traditional Methods

When comparing modern sheet metal forming techniques with traditional methods, the advantages are clear as day—efficiency reigns supreme! Roll forming machine technology minimizes waste material while maximizing output quality through precise engineering processes. Unlike older fabrication methods that often involve more manual labor and time-consuming adjustments, today's machinery allows for automated operations that save both time and resources.

Furthermore, using a roll forming machine for sale offers businesses an opportunity to invest in cutting-edge technology without breaking the bank. These machines come equipped with innovative features designed to enhance productivity while ensuring consistent results across all operations—something traditional techniques simply can't match! Overall, embracing modern sheet metal forming solutions leads to greater profitability and sustainability within various industries.

Choosing the Right Metal Machinery Supplier

In the world of metal fabrication, selecting the right metal machinery supplier can make or break your production efficiency. With numerous roll forming machine manufacturers available, it’s essential to pinpoint a supplier that aligns with your specific needs. Whether you're in the market for a roll forming machine for sale or seeking advanced sheet metal rolling machines, the choice you make will significantly impact your operations.

Factors to Consider

When evaluating potential suppliers, consider their reputation within the industry as well as their product range. Look for roll forming machine manufacturers that offer extensive options and customization capabilities tailored to your requirements. Additionally, assess their after-sales support and warranty policies; a reliable supplier should provide ongoing assistance and maintenance services for their sheet metal forming machines.

Another critical factor is technology and innovation—ensure that the suppliers you’re considering utilize modern techniques in their manufacturing processes. This is especially important when looking at metal rolling machines as advancements can lead to improved efficiency and precision in production. Lastly, pricing plays a significant role; seek out cost-effective solutions without compromising quality in your search for a dependable metal machinery supplier.

Leading Suppliers in the Market

Several key players dominate the landscape of roll forming machine manufacturers today. Companies like Kiant Machinery have established themselves by offering high-quality equipment coupled with excellent customer service, making them a top choice among those seeking sheet metal roll forming machines. Other notable suppliers include Formtek and Samco Machinery, both known for their innovative designs and robust product offerings.

These leading suppliers often have extensive catalogs featuring various types of roll forming machines tailored to different industries—from construction to automotive manufacturing. When considering these companies, it’s essential to review customer testimonials and case studies that showcase real-world applications of their machinery in action. This insight can help you gauge how well they meet customer expectations across various scenarios.

How to Evaluate Reliability and Support

Evaluating reliability and support from potential suppliers requires thorough research into their operational history and client feedback. Start by checking online reviews or industry forums where users share experiences regarding specific roll forming machine manufacturers or models of sheet metal rolling machines they’ve used. Pay attention not only to praise but also common complaints; this will give you a balanced view of what to expect.

Additionally, consider reaching out directly to suppliers for inquiries about technical support availability—prompt responses indicate a commitment to customer service that can be invaluable when issues arise with your equipment later on. Finally, ensure that they offer training services for operators; understanding how to effectively use your new machinery is crucial for maximizing productivity from day one.

Insights on Metal Rolling Machines

Metal rolling machines are an essential component in the manufacturing and construction industries, offering a range of capabilities that enhance productivity and efficiency. Understanding the different types of metal rolling machines available can help businesses choose the right equipment for their specific needs. From sheet metal rolling machines to specialized roll forming machines, each type plays a unique role in the production process.

Types of Metal Rolling Machines

When it comes to metal rolling machines, there are several types to consider, each designed for specific applications. The most common varieties include three-roll and four-roll bending machines, which are perfect for creating cylindrical shapes from sheet metal. Additionally, roll forming machines stand out by continuously shaping metal strips into desired profiles—ideal for manufacturers looking to streamline their production processes.

For those in need of flexibility and precision, sheet metal forming machines provide excellent options as well. These versatile tools can be used across various industries, making them invaluable assets for roll forming machine manufacturers who seek to cater to diverse client needs. Ultimately, selecting the right type of machine can significantly impact efficiency and product quality.

Innovative Technology in Metal Rolling

Innovation is at the heart of modern metal rolling technology, with advancements that significantly enhance performance and capabilities. Many roll forming machine manufacturers now incorporate automation features that improve accuracy and reduce labor costs while increasing output rates. This shift towards smart machinery not only boosts productivity but also allows businesses to adapt quickly to changing market demands.

Moreover, cutting-edge materials and design improvements have led to more durable and efficient sheet metal rolling machines. Enhanced software integration allows operators to monitor processes in real-time, ensuring consistent quality control throughout production runs. As technology continues to evolve, companies that invest in innovative solutions will likely gain a competitive edge in an ever-changing landscape.

Ensuring Quality and Precision

Quality assurance is critical when investing in any piece of machinery—especially when it comes to essential equipment like roll forming or sheet metal forming machines. Manufacturers must prioritize precision engineering during the selection process; after all, even minor deviations can lead to significant issues down the line. By choosing reputable metal machinery suppliers known for their commitment to quality standards, businesses can mitigate risks associated with subpar equipment.

Additionally, regular maintenance plays a vital role in ensuring that these complex machines operate efficiently over time. Implementing preventive measures not only extends the lifespan of your equipment but also maintains consistent output quality—a crucial factor for any successful operation involving roll forming or sheet metal processes. Ultimately, investing wisely in high-quality machinery solutions will pay dividends as companies strive for excellence.

Conclusion

In the ever-evolving world of construction, the significance of roll forming machines cannot be overstated. Manufacturers need to stay ahead of the curve by investing in advanced sheet metal forming machines that not only enhance efficiency but also reduce costs. By understanding the nuances of metal machinery suppliers and their offerings, businesses can make informed decisions that lead to long-term success.

Key Takeaways for Manufacturers

For manufacturers, recognizing the benefits provided by roll forming machine manufacturers is crucial. These machines streamline production processes, allowing for higher output with less waste and improved precision in sheet metal rolling. By comparing different models and understanding their capabilities, manufacturers can choose a roll forming machine that aligns with their specific needs.

Additionally, investing in quality equipment from reputable metal machinery suppliers ensures durability and reliability over time. The right sheet metal roll forming machine can significantly impact operations, making it essential to evaluate options carefully before making a purchase decision. Ultimately, staying informed about advancements in technology will empower manufacturers to remain competitive in a dynamic market.

The Future of Sheet Metal Forming

The future of sheet metal forming appears bright as innovations continue to emerge within this sector. Roll forming machines are becoming more sophisticated, integrating smart technology that enhances automation and precision while reducing operational costs. This trend indicates a shift towards more sustainable practices as manufacturers seek environmentally friendly solutions in their production processes.

Moreover, the demand for lightweight yet strong materials is increasing across various industries, driving further advancements in light gauge steel framing solutions. As these demands grow, so will the importance of choosing reliable roll forming machine manufacturers who offer cutting-edge technology tailored to meet evolving market needs. Embracing these changes will ensure that businesses remain relevant and profitable.

Investing Wisely in Machinery Solutions

Investing wisely in machinery solutions is paramount for any manufacturer looking to thrive in today’s competitive landscape. When searching for a roll forming machine for sale or exploring options among sheet metal rolling machines, it's essential to consider long-term value rather than just upfront costs. Quality equipment from trusted metal machinery suppliers often pays off through increased efficiency and reduced maintenance expenses over time.

Furthermore, evaluating potential suppliers based on customer support and reliability should be part of your strategy when seeking out new equipment or upgrades. It's not just about buying a piece of machinery; it's about building a partnership with those who understand your business needs and can provide ongoing assistance as you grow. In conclusion, thoughtful investment decisions today will pave the way for success tomorrow.