Introduction

In the world of construction, efficiency and precision are paramount, and that’s where roll forming steel framing comes into play. This innovative process allows for the creation of strong, lightweight structures that meet modern building demands. As we delve into the benefits of using steel framing machines, it becomes clear why they are a go-to choice for builders and manufacturers alike.

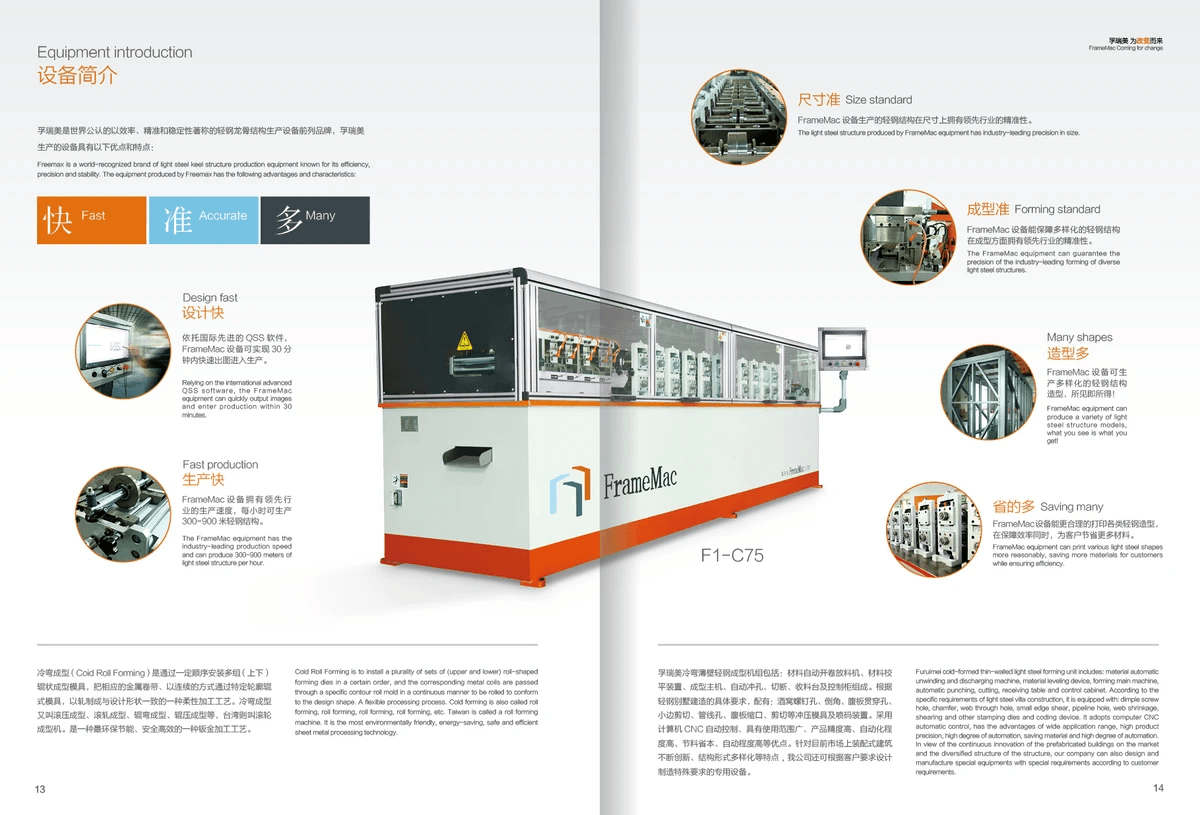

Overview of Roll Forming Steel Framing

Roll forming is a continuous bending process used to shape metal sheets into desired profiles, making it an ideal method for producing steel frames. The versatility of this technique allows for various applications, from residential buildings to large commercial projects. With advancements in technology, roll forming has become increasingly efficient and cost-effective, paving the way for widespread adoption.

Benefits of Using Steel Framing Machines

Steel framing machines offer numerous advantages over traditional wood framing methods. They provide enhanced durability and resistance to pests and weather-related issues while being lighter than their wooden counterparts. Moreover, utilizing a frame machine streamlines production processes, reducing labor costs and construction time significantly.

Key Features of Kiant Machinery's Products

Kiant Machinery stands out in the industry with its range of advanced steel framing solutions tailored to meet diverse needs. Their light steel frame machines boast cutting-edge technology that ensures precision engineering and high-speed production capabilities. Additionally, Kiant's commitment to customer satisfaction is evident through their robust support services and training programs designed to maximize machine efficiency.

Understanding Frame Machines

When it comes to modern construction, frame machines are the unsung heroes behind the scenes. These machines are designed to create a robust framework for various structures, particularly in steel framing applications. By automating the process of shaping and assembling materials, frame machines enhance efficiency and precision, making them indispensable tools in today's building industry.

What is a Frame Machine?

A frame machine is an advanced piece of equipment used primarily for fabricating structural frameworks from metal materials, such as steel. It operates by bending and cutting metal sheets into specific shapes that can be assembled into frames for buildings or other structures. The versatility of a frame machine allows it to cater to various projects, from residential homes to large commercial buildings, ensuring strength and stability.

Types of Frame Machines Available

There are several types of frame machines available on the market today, each tailored for specific applications and materials. Light Steel Frame Machines are particularly popular due to their ability to work with thin-gauge steel while maintaining structural integrity. Other variations include heavy-duty frame machines designed for larger steel components and specialized models that focus on particular framing styles or techniques.

Advantages of Using a Frame Machine

Using a frame machine offers numerous advantages that make it an attractive investment for builders and contractors alike. First off, these machines significantly reduce labor costs by automating tasks that would otherwise require extensive manual effort. Additionally, they ensure consistent quality in every piece produced—no more wonky frames! And let's not forget about time savings; with a well-functioning Light Gauge Steel Framing Machine at your disposal, project timelines can shrink dramatically.

Exploring Light Steel Frame Machines

When it comes to modern construction, the Light Steel Frame Machine is a game changer. These machines allow for quick and efficient production of steel frames, making them essential in various building applications. Whether you’re working on residential projects or commercial buildings, understanding light steel frame machines can significantly enhance your workflow.

Definition and Applications

A Light Steel Frame Machine is specifically designed to create lightweight yet durable steel frames for construction purposes. These machines utilize advanced technology to produce precise components that are easy to assemble on-site, streamlining the entire building process. Common applications include residential homes, office buildings, and even industrial structures where strength and weight savings are crucial.

The versatility of a frame machine means that it can cater to different architectural designs while maintaining structural integrity. This adaptability makes it an attractive option for builders looking to innovate without compromising quality or safety standards. With the growing demand for sustainable construction practices, light steel framing has gained popularity due to its recyclability and reduced environmental impact.

How to Choose a Light Steel Frame Machine

Choosing the right Light Steel Frame Machine involves several key considerations that can greatly affect your project’s success. First, assess the specific needs of your construction projects; this includes understanding the types of materials you'll be working with and the scale of production required. Look for features such as automation capabilities, ease of operation, and compatibility with various software systems that can enhance efficiency.

Next, consider the machine's build quality and reliability; investing in a robust frame machine ensures longevity and minimizes downtime during operations. Don’t forget about after-sales support—having access to training resources or technical assistance can make all the difference in getting your machinery up and running smoothly from day one. Lastly, always compare options based on performance reviews from other users in order to make an informed decision.

Light Gauge Steel Framing Machine Cost

When evaluating Light Gauge Steel Framing Machine cost, it's essential to understand what factors influence pricing beyond just initial investment figures. The price of a steel frame machine typically varies based on its features, brand reputation, and overall capabilities; therefore it's crucial not only to look at upfront costs but also long-term value propositions such as durability and maintenance requirements.

For instance, while some lower-priced options may seem appealing initially, they could lead to higher operational costs down the line due to frequent repairs or inefficiencies in production speed. Additionally, keep in mind that many manufacturers offer financing plans or leasing options which can help spread out costs while still allowing you access to high-quality equipment necessary for your business growth.

Ultimately investing in a quality light gauge steel framing machine represents not just an expense but rather a strategic move towards enhancing productivity within your operations—making it worth every penny spent!

Steel Frame Machine Price Analysis

When it comes to investing in a steel frame machine, understanding the price landscape is crucial for making informed decisions. Prices can vary significantly based on several factors, including machine specifications, brand reputation, and additional features. This section will delve into the elements that influence steel frame machine prices, provide a comparative analysis of various brands, and highlight the long-term value of investing in quality machinery.

Factors Influencing Steel Frame Machine Prices

Several key factors play a role in determining the price of a steel frame machine. First and foremost is the complexity and capabilities of the machine itself; advanced features such as automation and precision engineering typically come with higher price tags. Additionally, brand reputation can greatly influence pricing—well-established manufacturers often charge more due to their proven track record of reliability and service support.

Another significant factor is material costs; fluctuations in raw material prices can directly impact manufacturing costs for companies producing light gauge steel framing machines. Moreover, geographical location may also affect prices due to shipping fees or regional demand variations. Lastly, warranties and after-sales support can add value to your investment but may also contribute to higher upfront costs.

Comparing Prices Across Different Brands

When comparing prices across different brands for light steel frame machines, it’s essential to consider not just the sticker price but also what you’re getting for your money. Some brands might offer lower initial costs but skimp on features or customer support, while others might present a higher price point justified by superior technology and reliability. It’s wise to conduct thorough research by checking reviews and case studies from users who have invested in these machines.

For instance, Kiant Machinery may have slightly elevated prices compared to lesser-known brands due to their commitment to quality materials and innovative technology in their light gauge steel framing machines. However, this could translate into fewer maintenance issues down the line—an essential consideration when evaluating overall cost-effectiveness. A well-rounded comparison will help ensure you’re not only looking at purchase prices but also long-term operational efficiency.

Long-term Value of Investing in Quality Machines

Investing in a high-quality steel frame machine pays off over time through enhanced productivity and reduced maintenance costs. While cheaper alternatives might seem appealing initially, they often lead to more frequent breakdowns or inefficiencies that can drain resources quickly—both financially and operationally. By opting for reliable machinery like Kiant's offerings, businesses can enjoy smoother operations that ultimately boost profitability.

Moreover, quality machines tend to come with better technology integration options which can streamline processes further down the line—think automation features that save labor hours! When evaluating light gauge steel framing machine cost against expected longevity and performance improvements, it becomes clear that upfront investments are often counterbalanced by substantial savings over time. In short: investing wisely today means reaping rewards tomorrow!

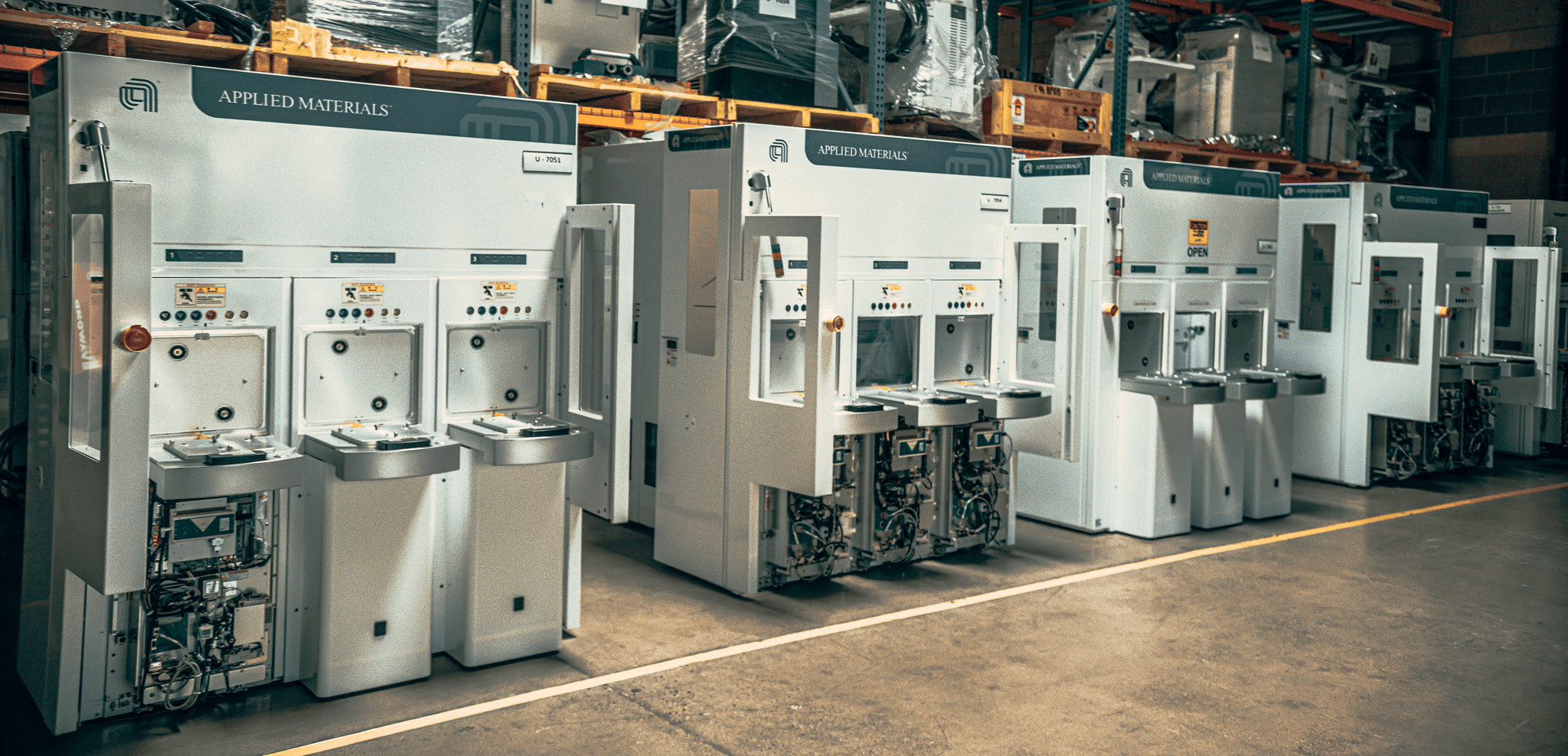

Kiant Machinery’s Advanced Solutions

Kiant Machinery is redefining the landscape of steel framing with its innovative solutions tailored for modern construction needs. Their commitment to quality and performance sets them apart in a competitive market, making their frame machines a top choice for builders seeking reliability and efficiency. With advanced technology integrated into their Light Steel Frame Machines, Kiant ensures that clients receive the best tools for their projects.

Features that Set Kiant Machinery Apart

One of the standout features of Kiant Machinery's products is their precision engineering, which enhances the accuracy of every cut and bend in the steel framing process. Their Light Gauge Steel Framing Machine incorporates cutting-edge technology that allows for seamless adjustments, ensuring flexibility in design while maintaining structural integrity. Additionally, these machines are designed for ease of use, making them accessible even to those new to steel framing.

Kiant's frame machines also boast energy efficiency and reduced waste during production, translating into cost savings over time. This attention to sustainability is increasingly important as businesses look to minimize their environmental impact while maximizing productivity. Furthermore, the durability of Kiant's machinery means fewer breakdowns and lower long-term maintenance costs—a significant consideration when evaluating Steel Frame Machine prices.

Customer Success Stories with Kiant Products

Kiant Machinery has garnered numerous success stories from satisfied customers who have transformed their operations with these advanced frame machines. For instance, a mid-sized construction firm reported a 30% increase in productivity after integrating a Light Steel Frame Machine into their workflow—allowing them to complete projects faster without sacrificing quality. Such testimonials highlight how investing in high-quality equipment can lead to significant operational improvements.

Another notable success comes from a large-scale developer who utilized Kiant's steel framing solutions on multiple housing projects simultaneously. They praised the machine’s ability to handle various designs efficiently while keeping costs manageable—an essential factor when considering Light Gauge Steel Framing Machine costs across different job sites. These real-world examples illustrate how Kiant’s products not only meet but exceed expectations in diverse applications.

Training and Support Services Offered

Understanding that purchasing a frame machine is just the first step in enhancing your business operations, Kiant Machinery provides comprehensive training and support services for all its products. New users can benefit from hands-on training sessions designed to familiarize them with machine functionalities and best practices—ensuring they can maximize productivity right from day one. This commitment to customer education sets Kiant apart as not just a supplier but also a partner in success.

Moreover, ongoing technical support ensures that clients have access to expert advice whenever needed—helping troubleshoot issues quickly and efficiently without halting production schedules. This level of service reinforces client confidence when investing in high-quality machinery like Light Steel Frame Machines or evaluating long-term Steel Frame Machine prices against potential returns on investment. With such robust support systems in place, it's no wonder customers consistently choose Kiant Machinery as their go-to provider for all steel framing needs.

Maintenance Tips for Steel Framing Machines

Maintaining your steel framing machines is not just a chore; it’s a vital investment in your production line's efficiency and longevity. Regular maintenance of frame machines, especially Light Gauge Steel Framing Machines, can prevent costly breakdowns and extend their operational life. By prioritizing upkeep, businesses can ensure they get the most out of their investments, including those hefty Light Steel Frame Machine costs.

Importance of Regular Maintenance

Regular maintenance is essential for keeping your frame machine running smoothly and efficiently. Just like any piece of machinery, neglecting routine check-ups can lead to unexpected downtimes and repairs that could have been easily avoided. Moreover, consistent maintenance helps maintain the quality of output, ensuring that your steel framing projects meet industry standards without unnecessary delays.

Common Maintenance Issues and Solutions

Steel frame machines often face common issues such as misalignment, wear on critical components, or even software glitches in more advanced models. For instance, if you notice uneven cuts or bends in your Light Gauge Steel Framing Machine output, it might be time to recalibrate the machine or check for worn-out blades. Addressing minor issues promptly not only saves money but also minimizes disruptions in production schedules—after all, no one wants to deal with unplanned downtime when there are projects to complete!

Extending the Lifespan of Your Machinery

To truly extend the lifespan of your steel framing machinery—whether it's a basic frame machine or an advanced model—invest in quality parts and regular professional servicing. Additionally, operators should be trained properly to handle these machines with care; after all, a well-informed operator is less likely to make mistakes that could lead to damage or inefficiencies. Finally, keeping an eye on the overall environment where these machines operate can also help; dust-free areas free from moisture tend to be kinder on machinery over time.

Conclusion

In the ever-evolving world of construction, investing in steel framing technology is not just a trend; it’s a necessity. Steel framing offers unmatched durability and flexibility compared to traditional methods, making it an ideal choice for modern building projects. By embracing advanced solutions like frame machines, builders can significantly enhance their productivity and project outcomes.

Why Invest in Steel Framing Technology

Investing in steel framing technology means committing to quality, longevity, and efficiency. With the rise of Light Steel Frame Machines, construction professionals can utilize lightweight materials that still provide robust structural integrity. Moreover, understanding the Light Gauge Steel Framing Machine cost is essential for budgeting effectively while reaping long-term benefits from reduced maintenance and increased strength.

Enhancing Efficiency with Kiant Machinery

Kiant Machinery stands out by offering innovative frame machines designed to streamline production processes. Their equipment not only boosts efficiency but also ensures precision in every cut and bend, which is crucial for high-quality steel framing projects. When you choose Kiant's products, you're not just investing in machinery; you're investing in a partnership that prioritizes your success through ongoing support and advanced training.

Future Trends in Steel Frame Manufacturing

The future of steel frame manufacturing looks promising with the integration of smart technologies into frame machines. Automation and AI are set to revolutionize how we approach construction, making processes faster and more efficient than ever before. As demand grows for sustainable building practices, light gauge steel framing will play a pivotal role in meeting these needs while keeping costs manageable—especially when you consider the long-term value associated with quality steel frame machine prices.