Introduction

In the world of construction and manufacturing, efficiency and precision are paramount. Enter the c channel roll forming machine, a vital piece of equipment that transforms steel sheets into versatile steel channels used across various industries. Understanding how these machines work and their significance can help businesses make informed decisions that enhance productivity.

Understanding C Channel Roll Forming Machines

C channel roll forming machines are designed to produce steel channels with remarkable accuracy and speed. These machines utilize a series of rollers to shape flat sheet steel into desired metal channel sizes, ensuring consistent quality throughout the production process. By automating this task, manufacturers can significantly reduce labor costs while increasing output, making it an attractive option for any business involved in metal fabrication.

The Role of Steel Channels in Construction

Steel channels play a crucial role in modern construction projects due to their strength and durability. They provide structural support in buildings, bridges, and various infrastructure applications, ensuring safety and stability in design. The versatility of steel metal channels allows engineers to tailor their specifications based on project requirements, making them indispensable in today's construction landscape.

Why Choose Kiant Machinery for Your Needs

Their advanced technology ensures high-performance machinery that delivers optimal results every time you work with sheet steel roll or metal roll sheet products. With exceptional customer support and training services, partnering with Kiant Machinery means you're not just buying equipment; you're investing in your success.

What is a C Channel Roll Forming Machine

When it comes to shaping steel into practical forms, the c channel roll forming machine stands out as a vital tool in the industry. This machine is designed specifically to create steel channels, which are essential components in various construction and manufacturing applications. By transforming flat steel sheets into precise metal channel sizes, this equipment plays a crucial role in enhancing structural integrity and efficiency.

Definition and Functionality

A c channel roll forming machine is an innovative piece of machinery that processes sheet steel roll into C-shaped channels. The functionality of this machine lies in its ability to take flat steel sheets and gradually bend them into the desired shape using a series of rollers and dies. This process not only ensures uniformity but also allows for high-speed production, making it an ideal choice for manufacturers looking to streamline their operations.

How It Works with Steel Sheets

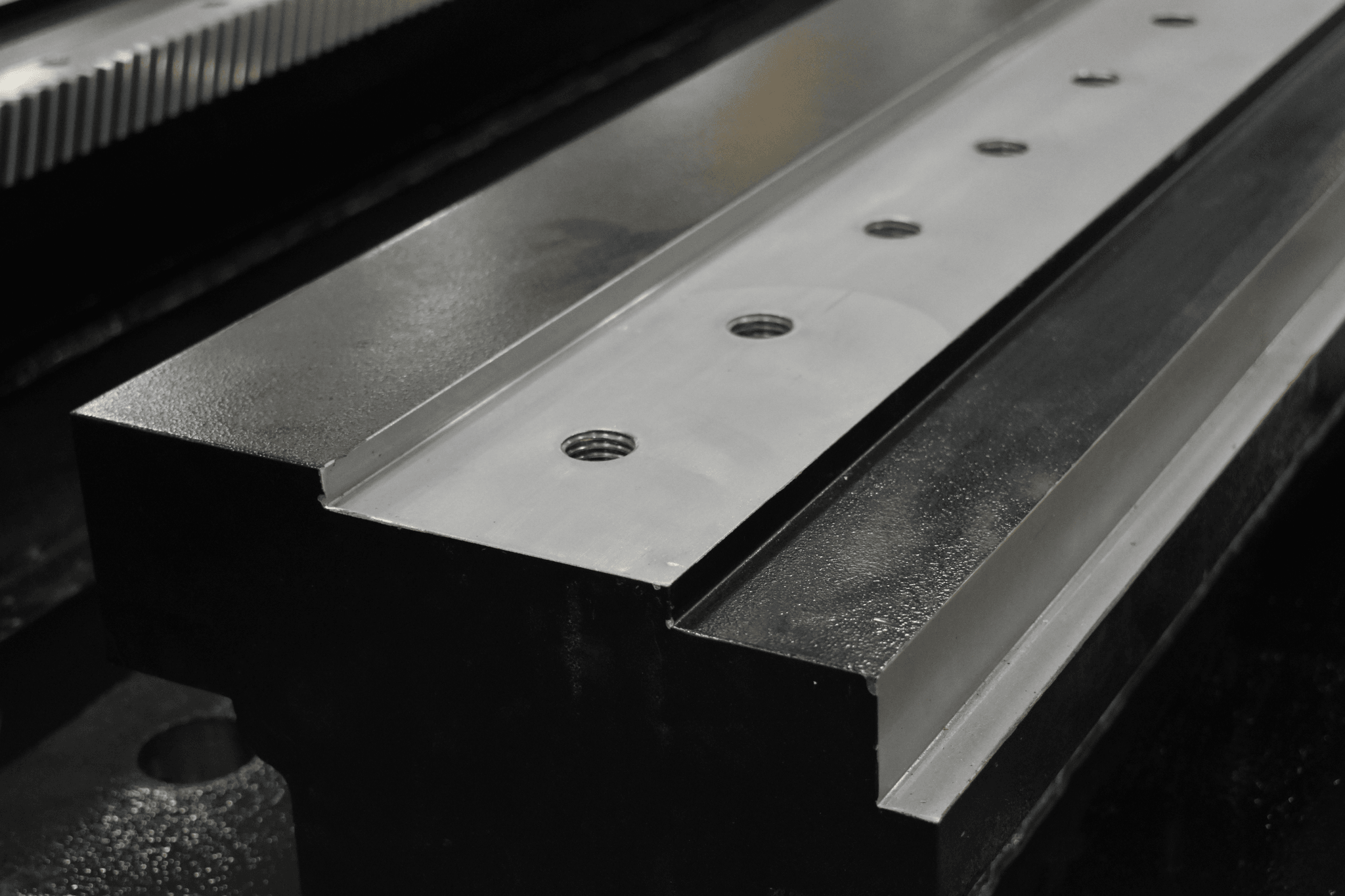

The operation of a c channel roll forming machine begins with feeding sheet steel rolls into the machine's entry point. As the steel sheet moves through various stages, it passes through multiple rollers that progressively shape it into a C-channel profile. This continuous process ensures minimal waste while maximizing output, allowing manufacturers to produce high-quality steel channels efficiently.

Advantages of Using C Channel Roll Forming

Using a c channel roll forming machine offers several advantages that make it an attractive option for businesses involved in construction or manufacturing. Firstly, these machines provide consistent quality across all produced items due to their automated nature, reducing human error significantly. Additionally, the versatility in metal channel sizes means that manufacturers can cater to different project requirements without needing multiple machines or setups, ultimately saving time and costs associated with production delays.

Benefits of Using Steel Channels

Steel channels are a staple in the construction industry, and for good reason. They offer a range of advantages that make them an ideal choice for various applications, especially when produced using a c channel roll forming machine. From unmatched strength to cost-effectiveness, steel channels are hard to beat.

Strength and Durability

When it comes to construction materials, strength is non-negotiable. Steel channels boast exceptional durability, making them resistant to bending and deformation under heavy loads. This resilience is particularly crucial in structural applications where safety and longevity are paramount; with steel metal channels, you can trust that your framework will stand the test of time.

Versatility in Metal Channel Sizes

One of the standout features of steel channels is their versatility in metal channel sizes. Whether you're looking for slender profiles or robust options, the c channel roll forming machine can produce a variety of dimensions tailored to your specific needs. This adaptability means that architects and builders can select the perfect size for each project without compromising on quality or performance.

Cost-Effectiveness in Construction

Cost-effectiveness is always a consideration in construction projects, and using steel channels offers significant savings over time. Thanks to their durability and strength, fewer materials may be required compared to weaker alternatives, which translates into lower overall costs for projects utilizing sheet steel roll methods. Additionally, with efficient production from metal roll sheets via modern machinery like the c channel roll forming machine, you can achieve high-quality results without breaking the bank.

Key Applications of C Channel Machines

C channel roll forming machines are versatile tools that play a crucial role in various industries. Their ability to efficiently produce steel channels from sheet steel roll makes them indispensable in modern manufacturing and construction processes. Here, we explore the key applications where these machines shine, showcasing their importance across different sectors.

Construction and Infrastructure

In the world of construction and infrastructure, steel channels are fundamental components used for framing, support structures, and various load-bearing applications. The strength and durability of these steel metal channels make them ideal for high-stress environments like bridges, buildings, and towers. With a c channel roll forming machine, manufacturers can create precise metal channel sizes tailored to specific project requirements, enhancing both safety and structural integrity.

Moreover, the use of c channel machines allows for quick production cycles that meet tight deadlines without compromising quality. This efficiency is particularly beneficial in large-scale projects where time is money. By choosing the right equipment from Kiant Machinery, contractors can ensure they have access to reliable solutions that streamline their construction processes.

Automotive and Industrial Use

The automotive industry relies heavily on c channel roll forming machines for producing essential components such as frames, brackets, and supports made from high-strength steel channels. These steel metal channels provide the necessary rigidity while also being lightweight enough to enhance vehicle performance and fuel efficiency. With customizable metal channel sizes available through advanced machinery options, manufacturers can easily adapt their designs to meet evolving automotive standards.

In addition to automotive applications, industrial settings utilize c channel machines for fabricating equipment supports and conveyor systems that require robust structural elements. The versatility of sheet steel rolls allows industries to innovate continuously while maintaining cost-effectiveness in production processes. As demand grows for more complex designs in industrial machinery, investing in cutting-edge c channel technology becomes increasingly important.

HVAC and Electrical Frameworks

Heating, ventilation, air conditioning (HVAC), and electrical frameworks also benefit significantly from the use of c channel roll forming machines. Steel channels are commonly employed as support structures for ductwork or electrical conduits due to their strength and resistance to environmental factors like corrosion or temperature changes. Utilizing a reliable c channel machine allows fabricators to create durable frameworks that ensure efficient airflow or safe electrical installations.

Additionally, with the ability to produce various metal channel sizes quickly using sheet steel rolls ensures that HVAC systems can be customized according to specific building designs or client needs without excessive lead times or costs involved in sourcing pre-made components. As energy efficiency becomes increasingly critical in building design, having flexible manufacturing capabilities through advanced machinery will be paramount for staying competitive in this sector.

Choosing the Right Equipment

Selecting the right equipment for your C channel roll forming needs is a crucial step in ensuring efficient production and high-quality output. With various options available, understanding the unique features and capabilities of each machine can make all the difference in your operations. Whether you're working with steel sheets or exploring different metal channel sizes, making an informed choice will set you up for success.

Factors to Consider

When choosing a C channel roll forming machine, several factors warrant careful consideration. First and foremost, assess the specific requirements of your project, including the dimensions and thickness of the steel sheet roll you'll be using. Additionally, consider the production speed and capacity of different machines to ensure they align with your operational goals while accommodating various steel metal channel specifications.

Another significant factor is reliability; investing in a robust machine can save you from costly downtime due to malfunctions or maintenance issues. Furthermore, look into the ease of operation and whether training or support services are provided by manufacturers like Kiant Machinery. This comprehensive approach will help you select a machine that not only meets your immediate needs but also supports future growth.

Comparing Metal Roll Sheet Options

Comparing metal roll sheet options is essential when selecting a C channel roll forming machine that fits your production line seamlessly. Different machines offer varying capabilities in terms of material compatibility—some may excel with thinner sheets while others handle thicker gauges more effectively. Understanding these nuances allows you to choose machinery that optimizes efficiency without compromising quality.

Moreover, consider how versatile each option is regarding metal channel sizes; some machines may offer adjustable settings for producing multiple profiles, which can enhance flexibility in meeting diverse project demands. It’s also wise to evaluate any additional features such as automated controls or integration with existing systems that can streamline operations further. Ultimately, a thorough comparison will empower you to make an educated decision tailored to your unique manufacturing environment.

Insights on Performance and Efficiency

Performance and efficiency are paramount when it comes to selecting a C channel roll forming machine for steel channels in construction applications. High-performance machines typically feature advanced technology designed for precision cutting and shaping of steel sheets into desired profiles with minimal waste generated during production runs. This precision not only enhances product quality but also contributes significantly to overall operational efficiency.

Additionally, consider energy consumption as part of your evaluation; machines that are energy-efficient can lead to substantial cost savings over time while reducing environmental impact—a win-win situation for both business and planet! Lastly, don’t overlook customer reviews or case studies related to specific models; real-world insights often reveal performance aspects that specifications alone cannot convey effectively.

Kiant Machinery’s Offerings

At Kiant Machinery, we pride ourselves on delivering top-notch solutions tailored to the needs of our clients in the construction and manufacturing sectors. Our offerings are designed to enhance efficiency and productivity in the use of steel channels, ensuring that your projects run smoothly from start to finish. With a focus on innovation, we provide advanced c channel roll forming machines that stand out in the market.

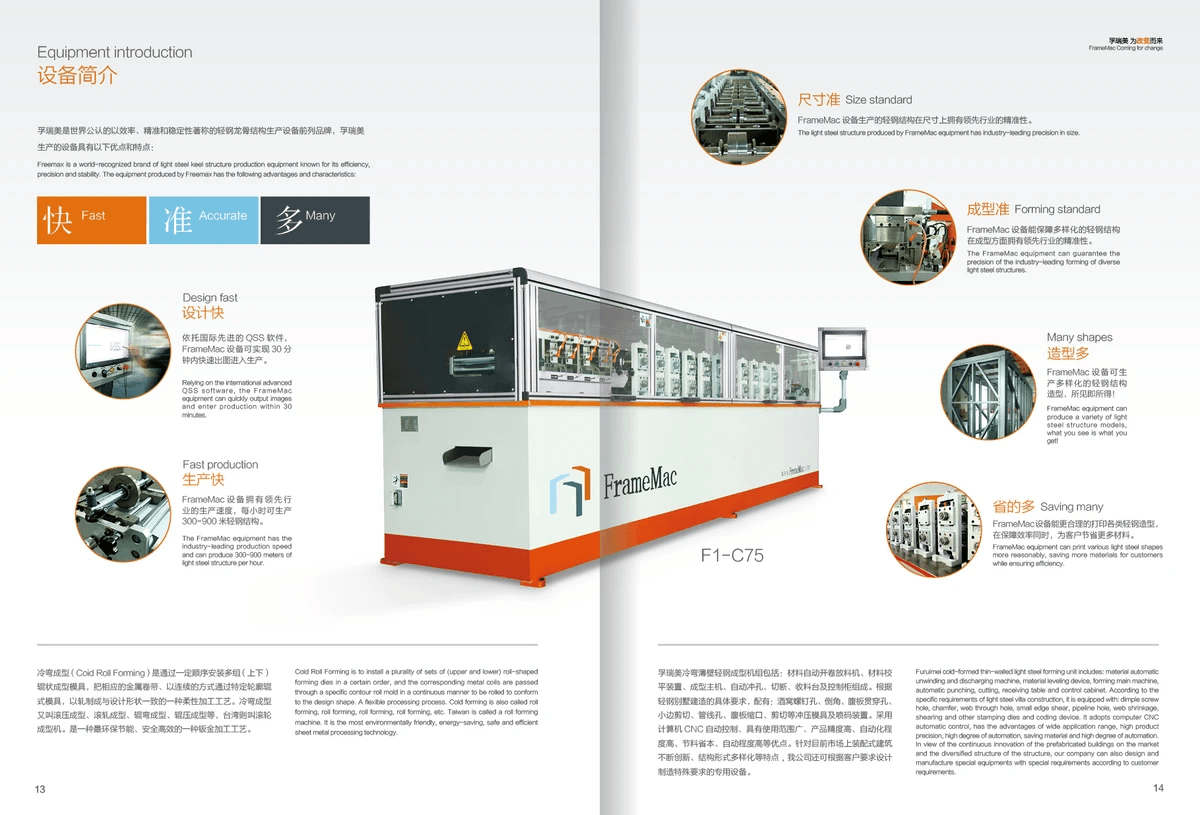

Advanced C Channel Roll Forming Solutions

Our advanced c channel roll forming machines are engineered for precision and versatility, making them ideal for producing various steel channel sizes with ease. These machines utilize state-of-the-art technology to transform sheet steel roll into high-quality metal channels that meet industry standards. Whether you require standard or customized dimensions, our solutions can accommodate your specific requirements without compromising on quality.

The benefits of our c channel roll forming solutions extend beyond just production; they also enhance operational efficiency by minimizing waste and reducing material costs. Our machines are designed for quick setup and easy operation, allowing you to ramp up production without extensive downtime. With Kiant Machinery’s offerings, you can trust that you’re investing in a reliable solution for all your metal roll sheet needs.

Training and Support Services

Understanding how to maximize the potential of your c channel roll forming machine is crucial for optimal performance. That’s why we offer comprehensive training programs tailored to help your team master the operation of our advanced machinery efficiently. From hands-on workshops to online tutorials, our training services ensure that your staff is well-equipped with the knowledge needed to operate steel sheet rolls effectively.

In addition to training, we provide ongoing support services designed to assist you throughout the lifecycle of your equipment. Our dedicated support team is always ready to address any questions or concerns regarding maintenance or troubleshooting issues related to steel channels or metal channel sizes. We believe that strong customer relationships are built on trust and reliability, which is why we prioritize responsive service at every step.

Customer Success Stories

Our commitment to excellence has resulted in numerous success stories from satisfied customers across various industries utilizing our c channel roll forming machines. One notable case involved a construction company that significantly increased its production capacity after integrating our technology into their workflow; they reported a 30% reduction in material waste thanks to precise cutting and shaping capabilities of our machines.

Another client from the automotive sector shared how switching to Kiant's equipment allowed them greater flexibility in creating custom steel channels for their vehicles while maintaining stringent quality standards. Such testimonials highlight not only the effectiveness of our metal roll sheet solutions but also demonstrate how partnering with Kiant Machinery can lead directly toward achieving operational goals.

Investing in a c channel roll forming machine from us means becoming part of an ever-growing community where success stories abound—proof that when you choose Kiant Machinery, you're not just selecting machinery; you're embracing a path toward innovation and growth.

Conclusion

In the ever-evolving landscape of construction and manufacturing, C channel roll forming machines stand out as vital tools that enhance efficiency and productivity. By streamlining the process of creating steel channels, these machines allow businesses to meet growing demands with precision and speed. The integration of advanced technology in steel sheet roll production ensures that manufacturers can produce high-quality products tailored to various applications.

Maximizing Efficiency with C Channel Machines

C channel roll forming machines are designed to optimize production workflows, minimizing waste while maximizing output. These machines utilize advanced techniques to process sheet steel rolls into precise metal channel sizes, ensuring consistency in every batch produced. With the ability to operate at high speeds and maintain accuracy, investing in a C channel roll forming machine can significantly elevate your production capabilities.

Moreover, the versatility offered by these machines allows for customization according to specific project requirements, making them indispensable in industries ranging from construction to automotive manufacturing. The use of steel channels not only enhances structural integrity but also contributes to cost savings through efficient material usage. By choosing the right equipment, businesses can achieve remarkable levels of efficiency that translate into increased profitability.

The Future of Steel Sheet Roll Technology

The future of steel sheet roll technology is bright and full of potential as innovations continue to emerge at a rapid pace. As industries demand more sustainable practices, advancements in C channel roll forming machines will likely focus on reducing energy consumption while enhancing performance capabilities. This shift towards eco-friendly manufacturing processes will not only benefit the environment but also provide companies with a competitive edge.

Additionally, integrating smart technologies such as automation and IoT into metal roll sheet production is set to revolutionize how manufacturers operate. These developments promise real-time monitoring and data analysis that can lead to improved decision-making processes and operational efficiencies. As we look ahead, it’s clear that embracing these technological advancements will be key for businesses aiming for success in an increasingly competitive market.

Partnering with Kiant Machinery for Success

With an extensive range of advanced machinery designed for optimal performance, Kiant Machinery ensures you have access to state-of-the-art equipment capable of handling various metal channel sizes efficiently and effectively.

Beyond just providing machinery, Kiant Machinery offers comprehensive training and support services designed to help you maximize your investment fully. Customer success stories highlight how partnering with Kiant has transformed operations across various sectors by improving product quality while reducing costs associated with inefficiencies or downtime. In this rapidly evolving industry landscape, aligning yourself with a reputable partner like Kiant Machinery could very well be the key ingredient for achieving lasting success.