Introduction

In the world of metal fabrication, rollforming machines stand out as essential tools for creating a variety of products with precision and efficiency. These machines are designed to shape and form metal sheets into specific profiles, making them invaluable in industries ranging from construction to automotive manufacturing. Whether you're considering a pinnacle rollforming machine or specialized Cold Formed Steel Framing Machines, understanding their capabilities is crucial for optimizing your production processes.

Understanding Rollforming Machines

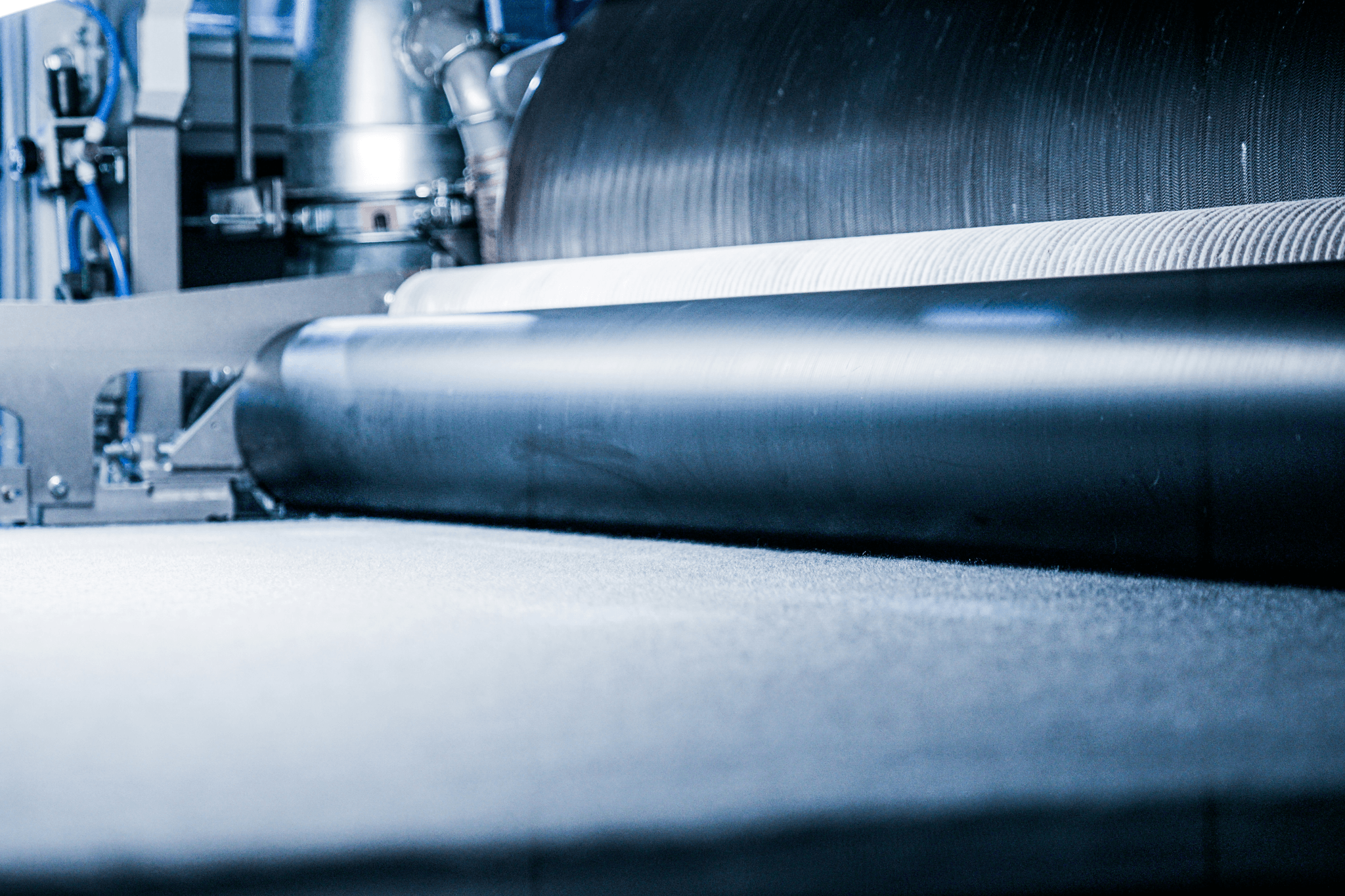

Rollforming machines operate by continuously feeding flat metal sheets through a series of rollers that gradually shape the material into desired forms. This process is particularly effective for producing long lengths of uniform profiles, which can be cut to size as needed. Familiarity with different types of rollforming machines, such as Lgs Steel Framing Machines, will help you select the right equipment tailored to your specific needs.

Key Factors in Machine Selection

When selecting a rollforming machine, various factors come into play that can significantly influence your decision-making process. Considerations like production volume, material type, and frequency of use are critical to ensuring you choose the right machine for your operations. Additionally, evaluating features such as speed and efficiency will enhance your overall productivity while minimizing downtime.

Common Applications for Rollforming

Rollforming machines are widely used across multiple industries due to their versatility and effectiveness in producing various components. From structural elements in buildings made with Cold Formed Steel Framing Machines to intricate designs found in automotive parts, these machines cater to diverse applications. By understanding common uses for rollformed products, you can better appreciate how these machines fit into the broader manufacturing landscape.

Types of Rollforming Machines

Rollforming machines come in various types, each designed to cater to specific manufacturing needs. Understanding the different variants is essential for selecting the right machine for your operation. From standard models to specialized machines, the options available can significantly impact production efficiency and output quality.

Overview of Machine Variants

Each type is engineered with unique features tailored to specific applications—whether it's for creating intricate profiles or producing lightweight yet strong components. Understanding these machine variants helps businesses make informed decisions about which equipment best suits their production requirements.

Custom vs. Standard Rollforming

In the world of rollforming, one of the primary choices is between custom and standard machines. Standard rollforming machines are typically more affordable and readily available, making them a popular choice for businesses with common production needs. On the other hand, custom rollforming solutions offer tailored specifications that can enhance efficiency but often come at a higher price point—ideal for those needing specialized outputs like Lgs Steel Framing Machines.

Pros and Cons of Each Type

As with any equipment choice, there are pros and cons associated with both custom and standard rollforming machines. Standard models tend to be quick to implement and cost-effective; however, they may not meet every unique requirement in highly specialized industries. Custom machines offer flexibility and precision but require a larger initial investment; thus companies must weigh their immediate needs against long-term goals when deciding which route to take.

Evaluating Your Production Needs

Assessing Volume Requirements

The first step in evaluating your production needs is to assess your volume requirements. How many units do you plan to produce daily or weekly? For instance, if you're considering a pinnacle rollforming machine, it's crucial to match its capabilities with your production goals; otherwise, you might end up with underutilization or overworking the equipment.

High-volume operations may require more robust machines like Cold Formed Steel Framing Machines that can handle larger batches without compromising quality. On the other hand, if you're producing smaller runs or custom items, a flexible LGS Steel Framing Machine might be more suitable for your needs. Ultimately, understanding these volume requirements will guide you toward making an informed investment.

Material Considerations

Material selection plays a significant role in determining which rollforming machine is best suited for your production line. Different materials have varying properties that affect how they can be processed; for instance, steel versus aluminum requires different handling techniques and machinery specifications. If you're working primarily with cold-formed steel, investing in specialized Cold Formed Steel Framing Machines can enhance efficiency and quality.

Moreover, consider the thickness and width of the materials you'll be using—these factors will dictate not only the type of rollforming machine needed but also its configuration and tooling options. Choosing a machine that aligns with your material requirements ensures that you maximize productivity while minimizing waste and rework costs.

Frequency of Use

Lastly, think about how often you'll be using your rollforming machine; this frequency will influence both initial investment decisions and long-term operational costs. If you're planning on running shifts daily or several times a week, opting for a pinnacle rollforming machine designed for high durability could save money over time through reduced maintenance and downtime.

Conversely, if your production runs are sporadic or seasonal, you might want to explore options that offer versatility without locking yourself into hefty investments—like an LGS Steel Framing Machine that adapts easily to various projects without sacrificing performance during less busy periods. Ultimately, assessing usage frequency helps ensure that you choose a solution tailored perfectly to fit within your operational rhythm.

Budgeting for Your Rollforming Machine

When considering the purchase of a rollforming machine, it's essential to balance the initial investment with long-term costs. A pinnacle rollforming machine may have a higher upfront cost, but its efficiency and durability can lead to significant savings over time. Understanding these financial aspects will help you make a more informed decision that aligns with your production goals.

Initial Investment vs. Long-term Costs

The initial investment in a rollforming machine can vary widely based on specifications and capabilities, particularly when comparing options like Cold Formed Steel Framing Machines or Lgs Steel Framing Machines. While you might be tempted to opt for the lowest price, remember that cheaper machines often come with higher maintenance costs and reduced efficiency. Investing in a quality pinnacle rollforming machine may seem like a stretch initially, but the potential for increased productivity and lower operational costs can pay off handsomely down the line.

Factors Affecting Price

Several factors play into the pricing of rollforming machines, including complexity, customization options, and brand reputation. For instance, custom-built Lgs Steel Framing Machines tend to cost more than standard models due to their tailored features designed for specific applications. Additionally, advanced technology integrations—like automation or enhanced safety features—can also drive up prices; however, these investments often yield better performance and reliability in your production line.

Financing Options Available

Financing options can significantly ease the burden of purchasing a new rollforming machine by spreading out costs over time. Many manufacturers offer leasing programs or financing plans that allow businesses to acquire essential equipment without straining cash flow upfront. Exploring these options not only helps manage expenses but also allows you to invest in high-quality machinery like Cold Formed Steel Framing Machines while keeping your budget intact.

Understanding Machine Specifications

Key Technical Features to Look For

When evaluating a rollforming machine, several technical features can make or break your decision. First and foremost, look for machines with adjustable tooling; this flexibility allows you to produce various profiles without needing extensive reconfiguration. Additionally, consider the power requirements of the machine—higher power often translates into better performance when working with tough materials like those used in Cold Formed Steel Framing Machines.

Another critical feature is the control system; modern rollforming machines often come equipped with advanced programmable logic controllers (PLCs) that enhance precision and ease of use. Also, pay attention to the forming speed; a pinnacle rollforming machine should ideally offer high-speed capabilities without sacrificing quality. Lastly, check for compatibility with different materials—machines designed for LGS Steel Framing Machine applications may need specific features tailored for lighter gauges.

Importance of Speed and Efficiency

Speed and efficiency are paramount when it comes to maximizing productivity in any manufacturing operation involving a rollforming machine. The faster you can produce high-quality products, the more competitive you become in your market space. Machines that boast higher throughput rates not only save time but also reduce labor costs associated with longer production runs.

Moreover, energy efficiency plays a significant role in long-term operational costs; investing in a high-efficiency pinnacle rollforming machine can lead to substantial savings on electricity bills over time. It’s essential to balance speed with quality—machines that operate too quickly may compromise on finishing standards or create waste due to errors in production processes. Therefore, finding an optimal balance between speed and precision is crucial for maintaining product integrity while boosting output.

Safety Features That Matter

Safety should never take a back seat when selecting a rollforming machine; after all, protecting your workforce is paramount for any successful operation. Look for machines equipped with emergency stop buttons easily accessible from multiple points around the equipment—this ensures quick action can be taken if something goes awry during operation. Additionally, safety guards should be present around moving parts to minimize risks associated with accidents.

Another vital consideration is overload protection; this feature helps prevent damage not only to the machinery itself but also safeguards against potential injuries caused by unexpected failures during heavy loads typical of Cold Formed Steel Framing Machines operations. Furthermore, opt for machines that offer user-friendly interfaces which simplify training processes—an informed workforce is generally safer as they understand how to operate machinery effectively without cutting corners on safety protocols.

Choosing a Reliable Manufacturer

When it comes to investing in a rollforming machine, selecting the right manufacturer is crucial for ensuring quality and performance. A reputable brand not only guarantees a reliable product but also provides peace of mind through excellent customer support and service. In an industry where precision and durability are paramount, the reputation of your chosen manufacturer can make all the difference.

Why Brand Reputation Counts

Brand reputation serves as a litmus test for quality in the world of rollforming machines. A well-established manufacturer often has years of experience, which means they have honed their craft and addressed common issues that arise in production processes. Additionally, positive reviews from other customers can provide insights into the reliability of both the equipment and after-sales support, making it easier to choose between options like Cold Formed Steel Framing Machines or Lgs Steel Framing Machines.

Moreover, a strong brand typically invests in research and development to stay ahead of technology trends, offering innovative solutions such as the pinnacle rollforming machine that enhances efficiency and productivity. When you opt for a reputable manufacturer, you’re not just buying machinery; you’re investing in long-term performance backed by solid customer testimonials. Ultimately, choosing a brand with a stellar reputation means you're less likely to face unexpected challenges down the road.

Spotlight on Kiant Machinery

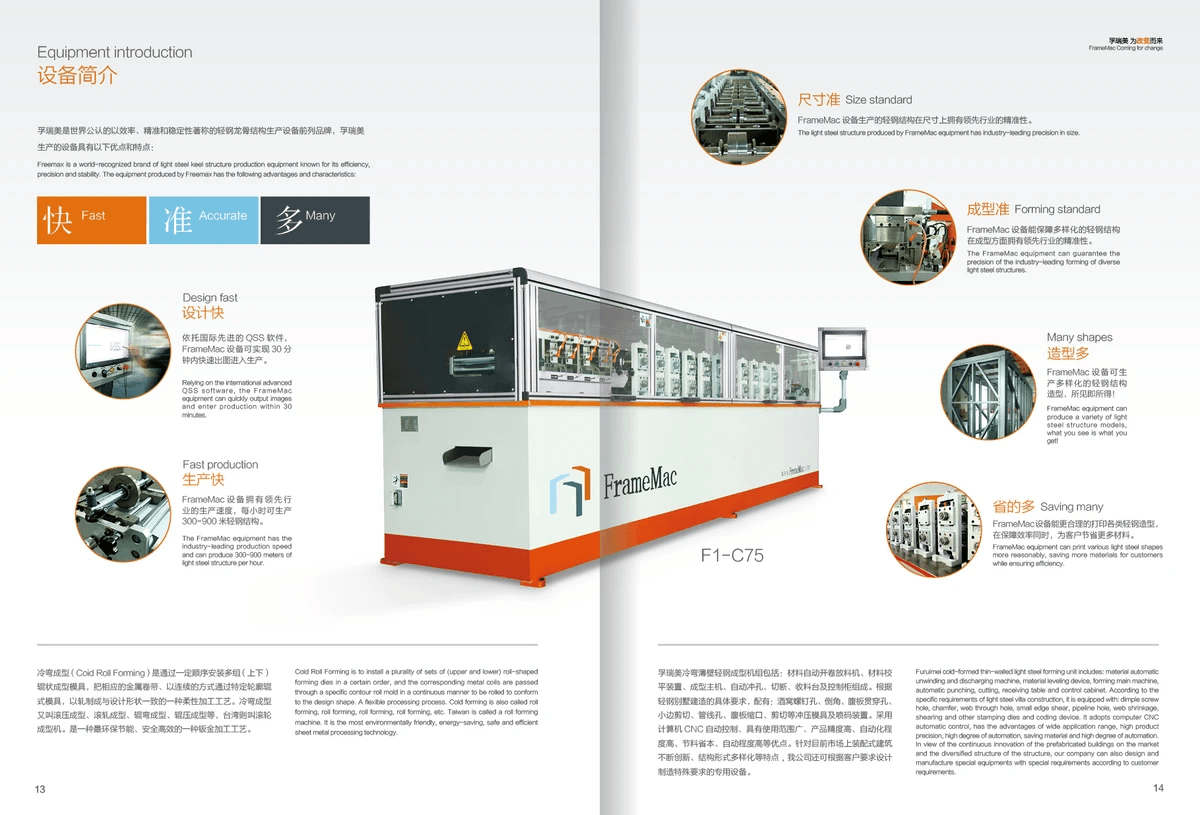

Kiant Machinery has carved out a niche for itself as one of the leading manufacturers in the rollforming industry. Known for its commitment to quality and innovation, Kiant offers an impressive range of products including Cold Formed Steel Framing Machines tailored to meet diverse production needs. Their pinnacle rollforming machine stands out due to its advanced features designed to maximize efficiency while minimizing waste.

One aspect that sets Kiant apart is its dedication to customization; they understand that each client has unique requirements and are willing to adapt their machines accordingly. This flexibility allows businesses using Lgs Steel Framing Machines or similar products from Kiant to achieve optimal results tailored specifically for their operations. With positive feedback from various industries highlighting both performance and reliability, Kiant Machinery certainly deserves your attention when considering options.

Evaluating Customer Support and Service

A reliable manufacturer doesn’t just sell you a rollforming machine; they also provide ongoing support that can be critical during installation or troubleshooting phases. Evaluate how responsive their customer service team is—are they available around-the-clock? Quick access to knowledgeable representatives can save time during unexpected breakdowns or maintenance needs.

Furthermore, consider whether they offer training sessions on using their machines effectively; this is especially important when dealing with complex systems like Cold Formed Steel Framing Machines or specialized models such as Lgs Steel Framing Machines. Good after-sales support ensures that your investment continues providing value long after purchase by optimizing operational efficiency through proper usage guidance and timely repairs when necessary.

When searching for your next rollforming machine supplier, remember: it's not just about getting any machine but securing one backed by dependable service!

Conclusion

In the ever-evolving world of manufacturing, making informed decisions regarding your rollforming machine can significantly impact your production efficiency and overall profitability. By understanding the various types of machines available, such as the pinnacle rollforming machine and Cold Formed Steel Framing Machines, you can select a solution that best fits your operational needs. Remember, investing in a quality Lgs Steel Framing Machine isn't just about initial costs; it's about long-term performance and adaptability.

Making Informed Decisions on Machines

Choosing the right rollforming machine requires careful consideration of several key factors, including production volume, material types, and specific application requirements. The pinnacle rollforming machine stands out for its versatility and efficiency across various projects, making it an excellent choice for businesses with diverse needs. Additionally, understanding whether to go with a custom or standard model will help tailor your investment to meet both current demands and future growth.

The Importance of After-Sales Support

Once you've invested in a rollforming machine, such as a Cold Formed Steel Framing Machine or Lgs Steel Framing Machine, after-sales support becomes crucial for maintaining optimal operation. A reliable manufacturer should provide comprehensive customer service options to address any issues that arise post-purchase effectively. This support can include training programs for staff, readily available spare parts, and quick response times for repairs—ensuring that your production line remains efficient without unnecessary downtime.

Future Trends in Rollforming Technology

As technology advances at breakneck speed, so too does the landscape of rollforming machinery. Emerging trends include enhanced automation features in machines like the pinnacle rollforming machine that streamline operations while improving precision and reducing waste materials. Additionally, innovations in materials science are leading to more robust designs for Cold Formed Steel Framing Machines and Lgs Steel Framing Machines—making them not only more efficient but also environmentally friendly as industries strive toward sustainability.