Introduction

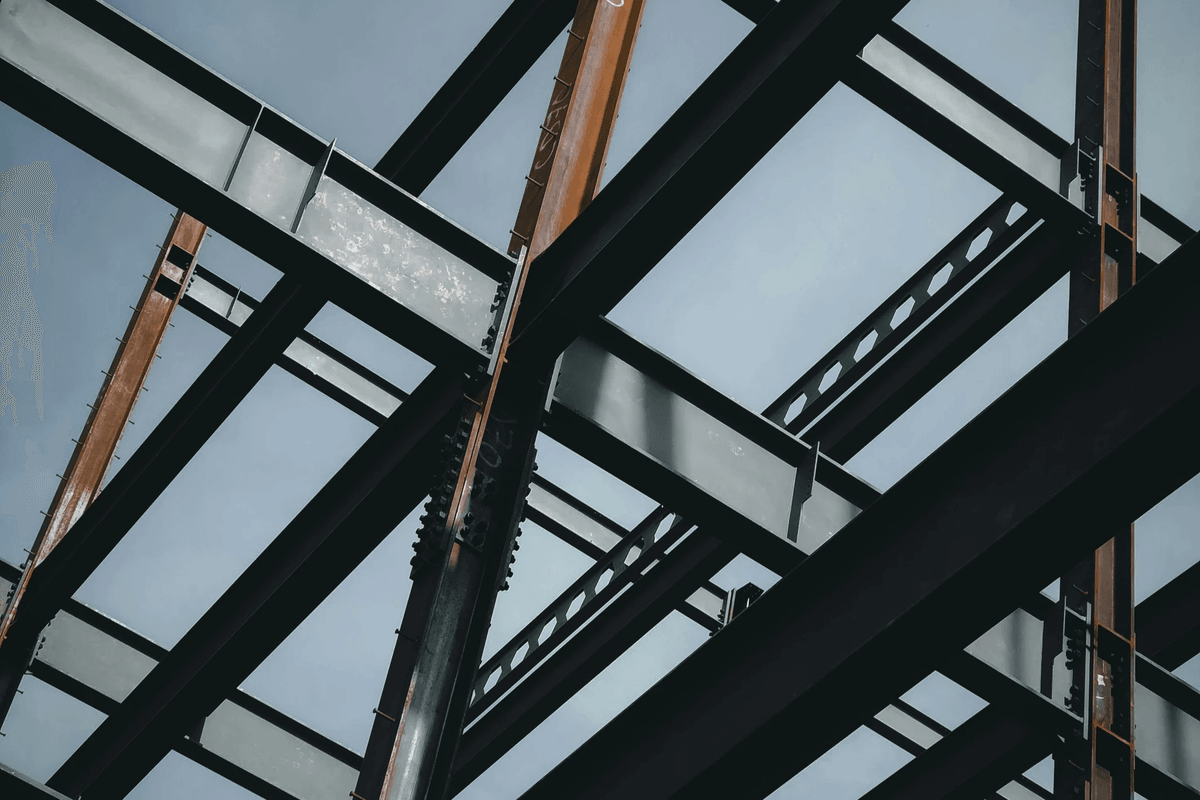

In recent years, light gauge steel framing has emerged as a game-changer in the construction industry, revolutionizing how we think about building structures. With its lightweight yet durable nature, lgs steel framing offers an innovative alternative to traditional materials, making it a popular choice among builders and homeowners alike. As the demand for more efficient and sustainable construction solutions grows, light gauge steel frame construction is gaining traction across various sectors.

The Rise of Light Gauge Steel Framing

The rise of light gauge steel framing can be attributed to its remarkable versatility and strength compared to conventional wood framing. Cold formed steel provides a robust framework that can withstand environmental challenges while remaining lightweight and easy to handle on site. This trend is not just a fleeting fad; it reflects a fundamental shift towards more resilient construction practices that prioritize longevity and efficiency.

Benefits of Choosing Steel Frame Construction

Choosing steel frame construction comes with a multitude of benefits that appeal to both builders and property owners. For starters, lgs steel framing offers exceptional durability and resistance to common issues like rot, pests, and fire hazards—problems often associated with traditional wood structures. Additionally, the long-term cost efficiency of using cold formed steel makes it an attractive investment for those looking to build with sustainability in mind.

Light Gauge Steel vs. Traditional Wood Framing

When comparing light gauge steel to traditional wood framing, several key differences emerge that highlight the advantages of using a modern steel framing system. While wood can warp or decay over time due to moisture exposure or pest infestations, lgs steel framing remains stable regardless of environmental conditions. Furthermore, light gauge steel frame construction allows for greater design flexibility and faster assembly times than its wooden counterparts—making it an appealing option for contemporary builders looking for efficiency without sacrificing quality.

What is Light Gauge Steel Framing?

Light gauge steel framing (LGS) is revolutionizing the construction industry, offering a modern alternative to traditional materials. This innovative method utilizes thin sheets of cold-formed steel to create a robust and versatile framework for buildings. As architects and builders increasingly embrace this technique, understanding its components and characteristics becomes essential.

Definition and Overview

Light gauge steel framing refers to the use of thin steel sections that are manufactured through a process called cold forming. These sections are typically less than 3/16 inches thick, making them lightweight yet incredibly strong. This type of steel framing system is ideal for both residential and commercial construction, providing structural integrity without the bulkiness associated with traditional wood framing.

Cold Formed Steel Explained

Cold formed steel (CFS) is the backbone of light gauge steel frame construction, produced by shaping flat strips of steel into various profiles without any heat application. This process not only enhances the strength-to-weight ratio but also allows for precise manufacturing tolerances, resulting in high-quality components for building projects. The flexibility of cold formed steel enables it to be easily molded into different shapes and sizes, catering to diverse architectural designs.

Key Differences with Traditional Steel Framing

When comparing light gauge steel framing with traditional steel framing systems, several key differences emerge that highlight LGS's unique advantages. First off, light gauge options are significantly lighter than their heavier counterparts while still maintaining structural strength—this makes handling and installation much easier on-site. Additionally, unlike traditional wood framing which can warp or shrink over time due to moisture fluctuations, light gauge steel remains stable and resistant to such issues, making it a reliable choice for long-lasting construction projects.

Advantages of Light Gauge Steel Frame Construction

When it comes to construction, light gauge steel framing (LGS) is rapidly becoming the go-to choice for many builders and developers. This innovative approach offers a myriad of advantages over traditional building methods, making steel frame construction an attractive option for both residential and commercial projects. Let's dive into the key benefits that make light gauge steel frame construction a smart investment.

Durability and Longevity

Light gauge steel framing is renowned for its exceptional durability and longevity, which are crucial factors in any construction project. Unlike traditional wood framing, LGS does not warp, crack, or shrink over time, ensuring that structures maintain their integrity even under extreme conditions. Additionally, cold formed steel used in these systems is resistant to corrosion when properly treated, providing a long-lasting solution that can withstand the test of time.

The robustness of light gauge steel also means fewer repairs and replacements down the line, ultimately saving both time and money for property owners. Builders appreciate that they can rely on this material to deliver consistent performance throughout its lifespan. In essence, investing in a steel framing system ensures that your structure remains resilient against Mother Nature's whims.

Resistance to Pests and Fire

One of the standout features of LGS steel framing is its impressive resistance to pests and fire hazards—two significant concerns in any building project. Unlike wood framing that can be susceptible to termites and other infestations, light gauge steel provides no sustenance for pests, effectively eliminating this risk altogether. This inherent pest resistance not only safeguards the structure but also contributes to lower maintenance costs over time.

Moreover, when it comes to fire safety, cold formed steel boasts superior performance compared to traditional materials like wood or vinyl siding. Steel does not ignite or contribute fuel during a fire incident; instead, it maintains structural integrity longer than many alternatives while offering peace of mind to homeowners and business operators alike. Choosing a light gauge steel frame construction means prioritizing safety without compromising on design flexibility.

Cost Efficiency in the Long Run

While some may argue that initial costs for lgs steel framing can be higher than traditional methods due to material pricing or specialized labor requirements, it's essential to consider long-term savings as well. The durability of light gauge steel frame construction translates into fewer repairs and maintenance expenses over its lifespan—often outweighing any upfront investment concerns associated with initial procurement costs.

Additionally, because LGS is lightweight yet strong, transportation costs are reduced significantly during delivery compared with heavier materials like concrete or solid timber frames. This efficiency extends into labor expenses as well; professionals skilled in installing a steel framing system often complete projects more quickly due to streamlined processes associated with these materials—saving you valuable time and money overall! So while you might pay slightly more at first glance for cold formed steel solutions today—the returns on investment will surely make you smile tomorrow.

Applications of Steel Framing Systems

The versatility of steel framing systems has made them a popular choice across various construction sectors. Whether it’s residential homes, commercial buildings, or pre-engineered structures, light gauge steel framing (LGS) offers unique advantages that traditional materials simply cannot match. With its strength and adaptability, LGS steel framing is redefining how we think about building.

Residential Construction Solutions

In the realm of residential construction solutions, light gauge steel frame construction is becoming increasingly favored by builders and homeowners alike. The durability of cold formed steel ensures that homes can withstand the test of time while also being resistant to pests such as termites and rodents—something wood framing can't always guarantee. Moreover, LGS steel framing allows for more open floor plans and creative designs without compromising structural integrity.

Additionally, the speed of assembly with steel frame construction can significantly reduce labor costs and project timelines in residential projects. Builders can erect homes faster than traditional wood-frame houses due to the precision engineering involved with light gauge steel framing systems. This efficiency not only saves money but also minimizes disruption in neighborhoods during construction.

Commercial Projects and Innovations

When it comes to commercial projects and innovations, the applications of light gauge steel are virtually limitless. Architects are leveraging cold formed steel's lightweight properties to create stunning facades while maintaining structural strength—a perfect marriage for modern urban environments where space is at a premium. Moreover, the adaptability of LGS allows for easy modifications or expansions down the line without major overhauls.

Steel frame construction also excels in meeting stringent building codes often required for commercial spaces, ensuring safety while providing design flexibility that wood simply cannot offer in larger-scale applications. From retail spaces to office buildings, using a robust steel framing system guarantees longevity and resilience against environmental stressors like wind or seismic activity.

Pre-Engineered Structures

Pre-engineered structures represent another area where light gauge steel shines brightly in modern construction practices. These systems utilize prefabricated components made from cold formed steel that can be assembled on-site quickly and efficiently—perfect for warehouses or industrial facilities needing rapid deployment without sacrificing quality or safety standards. The use of LGS not only speeds up project timelines but also reduces waste associated with traditional building methods.

Furthermore, pre-engineered structures benefit from being customizable according to specific needs while still adhering to strict regulations and standards set forth by local authorities—making them an ideal solution for businesses looking for functional yet stylish spaces. The cost-effectiveness associated with these types of constructions makes them particularly attractive in competitive markets where budgets are tight but quality cannot be compromised.

The Manufacturing Process of Light Gauge Steel

The manufacturing process of light gauge steel framing is a fascinating blend of technology and craftsmanship. It all begins with the creation of cold-formed steel, which is the backbone of any robust steel framing system. Understanding this process is essential for anyone interested in the benefits and applications of light gauge steel frame construction.

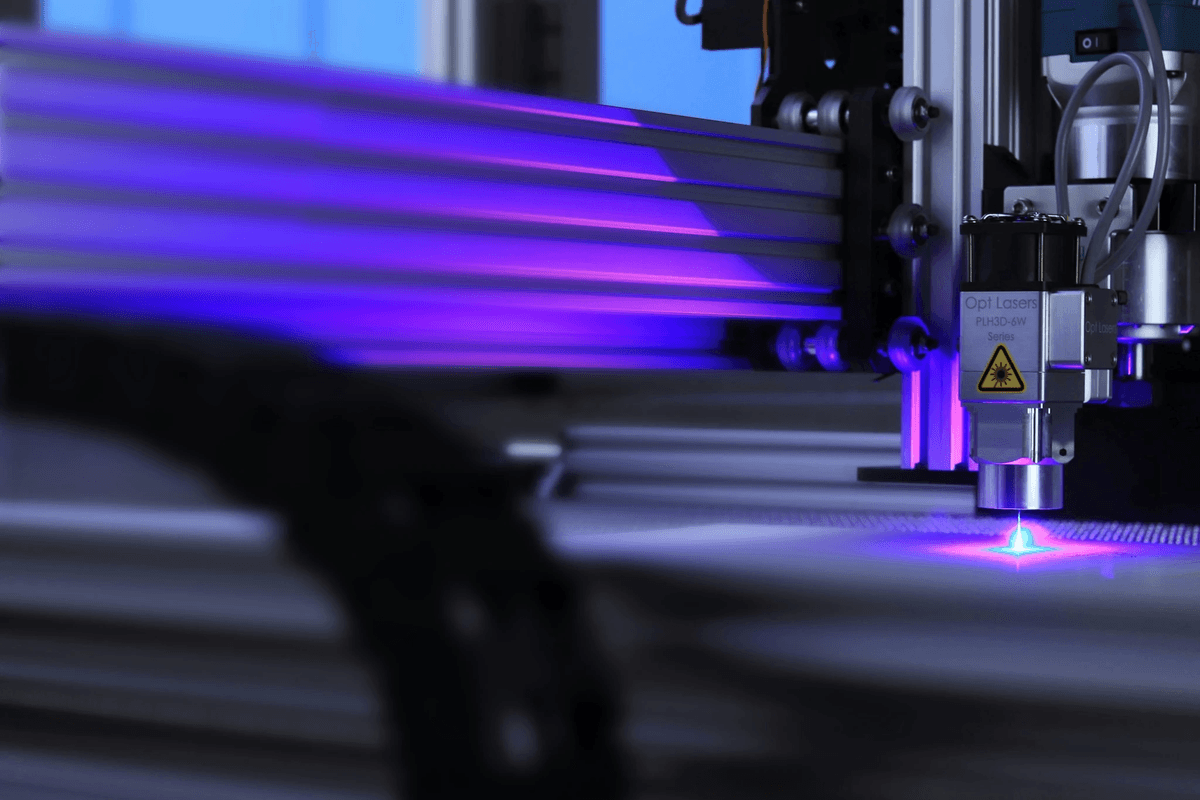

How Cold Formed Steel is Made

Cold formed steel starts its journey as flat sheets or coils of raw steel, which are then shaped into various profiles through a series of rollers and presses. This method not only enhances the strength but also allows for precise dimensions, making it ideal for lgs steel framing applications. The result is a lightweight yet incredibly durable material that can withstand various environmental stressors, setting it apart from traditional wood framing.

Once shaped, the cold-formed sections are cut to length and prepared for assembly into a complete steel framing system. This efficient manufacturing process minimizes waste and maximizes structural integrity, allowing builders to create strong frameworks with fewer resources. In addition, cold formed steel's resistance to warping or twisting ensures that every component fits perfectly during installation.

Role of Kiant Machinery in Production

Kiant Machinery plays an essential role in the production of light gauge steel framing systems by providing advanced machinery designed specifically for this purpose. Their equipment streamlines the manufacturing process, ensuring that each piece of cold formed steel meets stringent quality standards while being produced at high speeds. With innovative technology at their disposal, Kiant Machinery helps manufacturers optimize their operations and reduce costs associated with lgs steel framing production.

Moreover, these machines are engineered to handle varying thicknesses and profiles of cold formed steel efficiently. This versatility allows manufacturers to cater to diverse construction needs—ranging from residential homes to large commercial projects—while maintaining consistency in quality across all products. As a result, Kiant Machinery contributes significantly to enhancing productivity within the light gauge steel frame construction industry.

Quality Control Measures

Quality control measures are paramount in ensuring that every component used in a light gauge steel framing system adheres to industry standards and specifications. Manufacturers implement rigorous testing protocols throughout the production process—from raw materials inspection to final product evaluation—to guarantee durability and performance under various conditions. These measures help identify potential issues early on, preventing costly mistakes down the line during installation or use.

Additionally, regular audits and certifications ensure compliance with building codes and safety regulations specific to cold formed steel applications. This commitment to quality not only reinforces trust between manufacturers and builders but also promotes confidence among end-users regarding the longevity and reliability of their structures built using lgs steel framing systems. Ultimately, effective quality control translates into successful projects that stand the test of time.

Installation and Construction Best Practices

Tips for Effective Steel Frame Construction

To kick off your light gauge steel frame construction project on the right foot, start with thorough planning and design. Utilize advanced software tools that specialize in LGS steel framing to create precise blueprints that account for structural integrity and load distribution. During installation, ensure that all members are correctly aligned and secured; this is crucial for maintaining the overall strength of your steel framing system.

Additionally, always use high-quality fasteners designed specifically for cold formed steel to enhance durability and performance. Properly train your crew on the unique characteristics of light gauge steel framing; understanding how it behaves under various conditions will lead to better outcomes. Finally, regular inspections throughout the construction process can help catch any potential issues early on.

Common Mistakes to Avoid

Even seasoned builders can stumble when transitioning from traditional wood framing to light gauge steel framing. One common pitfall is neglecting the importance of moisture management; unlike wood, which can absorb water, cold formed steel requires careful consideration regarding drainage and waterproofing solutions. Failing to account for thermal bridging is another mistake; insulation techniques must be adjusted accordingly when working with a metal framework.

Another frequent error involves improper loading practices; overloading certain sections of a steel frame can lead to structural failure down the line. Additionally, miscalculating material quantities often results in delays or increased costs—always double-check your estimates! Lastly, avoid rushing through inspections or cutting corners during assembly—this could compromise the integrity of your entire structure.

Importance of Professional Expertise

While DIY projects may seem appealing in theory, light gauge steel frame construction is best left in the hands of professionals who understand its complexities. Professional expertise ensures that all aspects—from design through installation—are executed correctly according to industry standards specific to LGS steel framing systems. Their experience with cold formed steel allows them to anticipate challenges that may arise during construction.

Moreover, hiring skilled professionals helps mitigate risks associated with safety regulations and building codes that are paramount in any construction project involving metal frameworks. With their knowledge base at hand, you’ll benefit from insights into innovative techniques and technologies that enhance efficiency while adhering strictly to quality control measures during production and assembly phases.

In conclusion, investing time into understanding installation best practices will pay off significantly when leveraging light gauge steel framing advantages in construction projects. Whether you're involved in residential or commercial builds, these tips will guide you toward success while avoiding common pitfalls along the way.

Conclusion

In wrapping up our exploration of light gauge steel framing, it’s clear that this innovative approach is not just a fleeting trend; it’s a substantial leap forward in construction technology. With its myriad benefits, including durability and cost efficiency, light gauge steel frame construction is poised to redefine how we build for the future. As we look ahead, it's essential to consider the potential of LGS steel framing in meeting the demands of modern architecture and sustainable design.

Future of Light Gauge Steel in Construction

The future of light gauge steel framing looks promising as more builders and architects recognize its advantages over traditional materials. With advancements in cold formed steel technology, the design possibilities are expanding, allowing for more complex and aesthetically pleasing structures without compromising on strength or safety. As urbanization continues to rise globally, adopting a robust steel framing system will be crucial for creating resilient buildings that can withstand environmental challenges.

Environmental Impact and Sustainability

Light gauge steel frame construction offers significant environmental benefits compared to conventional wood framing methods. Steel is 100% recyclable, which means that using LGS steel framing contributes to reduced waste and promotes sustainability within the construction industry. Furthermore, the longevity and durability of cold formed steel structures mean fewer resources are consumed over time for repairs or replacements, making it an eco-friendly choice for future projects.

Choosing the Right Steel Framing Partner

When embarking on a project utilizing light gauge steel framing, selecting the right partner is paramount to ensure success. Look for companies with extensive experience in steel frame construction who understand both the technical aspects and practical applications of LGS steel framing systems. A solid partnership can lead to innovative solutions tailored specifically to your needs while ensuring quality craftsmanship throughout every stage of your project.