Introduction

In the ever-evolving world of metal fabrication, the rise of handheld pipe cutting machines has revolutionized how professionals approach their projects. With advancements in technology, these versatile tools have become indispensable for tasks like cutting iron pipes and steel tubes. Whether you're a seasoned tradesperson or a DIY enthusiast, understanding the benefits of using a pipe cutter can significantly enhance your efficiency and precision.

The Rise of Handheld Pipe Cutting Machines

Handheld pipe cutting machines have surged in popularity due to their convenience and effectiveness in various applications. From construction sites to home workshops, these tools offer a level of portability that traditional cutting methods simply can't match. As industries increasingly prioritize efficiency and safety, the demand for reliable tools like cast iron pipe cutters has skyrocketed.

Why Choose a Pipe Cutter for Your Needs

Choosing a pipe cutter over other cutting methods can streamline your workflow and yield cleaner cuts with minimal effort. These specialized tools are designed specifically for cutting pipes, making them more efficient than saws or torches when it comes to iron tube cutting or steel pipe cutter applications. Plus, investing in a quality pipe cutting tool ensures you get consistent results every time—an essential factor for any serious project.

Key Features of a Good Pipe Cutter

When selecting the right pipe cutter, several key features can make all the difference in performance and user experience. Look for models that offer adjustable blade settings to accommodate different material thicknesses—this is particularly important when working with various types of metal like cast iron or steel. Additionally, ergonomic designs that reduce hand fatigue during prolonged use will keep you comfortable while tackling even the toughest jobs at places like Home Depot or your local hardware store.

Understanding Handheld Pipe Cutting Machines

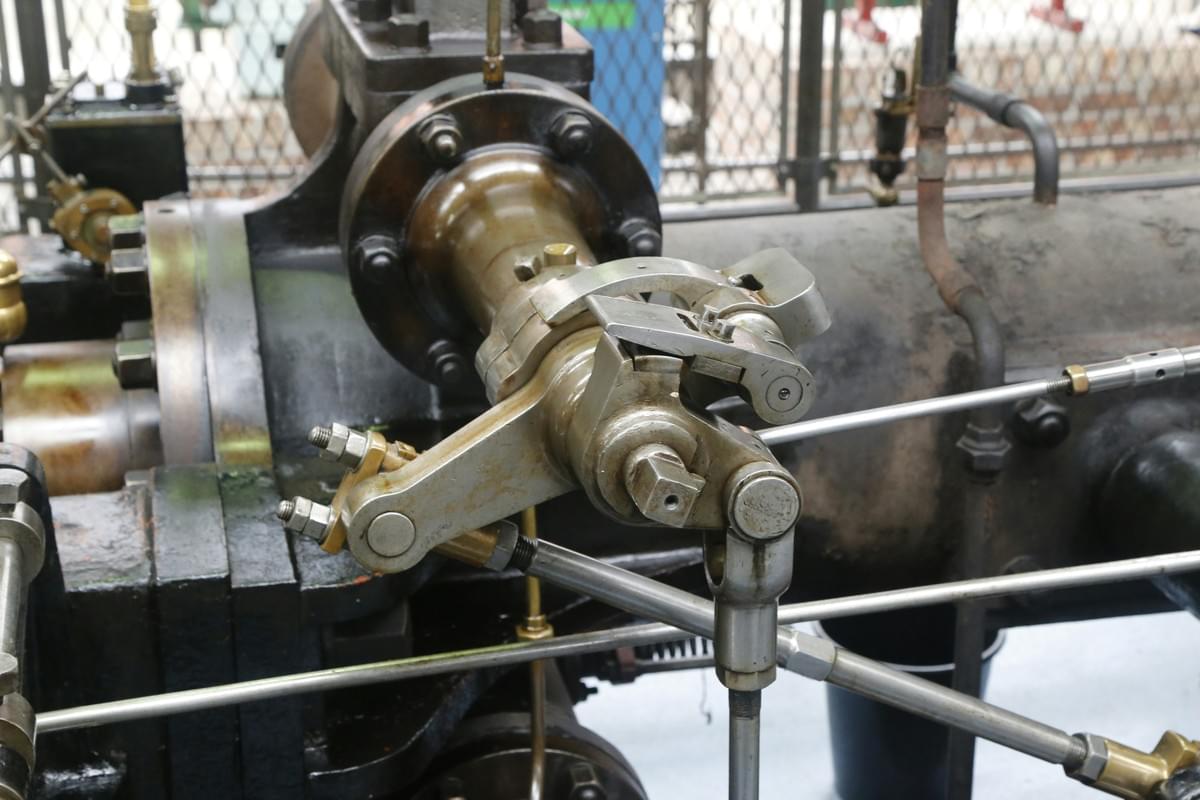

What Makes Them Different

Handheld pipe cutting machines stand out due to their portability and ease of use. Unlike stationary cutters that limit your mobility, these pipe cutters allow you to work in tight spaces or on-site without sacrificing performance. Their design typically incorporates ergonomic features, making them comfortable for extended use—perfect for those long days of cutting iron pipe or tubing.

Advantages Over Traditional Cutting Methods

The advantages of using a handheld pipe cutter over traditional methods are numerous. For starters, they significantly reduce the time it takes to complete a job; you can go from cutting iron tube to finishing in record time. Additionally, these tools provide cleaner cuts with minimal burrs, which is crucial when working with steel or cast iron pipes where precision matters most.

Common Uses in Various Industries

Handheld pipe cutters find applications across multiple industries—from plumbing and HVAC to automotive and construction. In plumbing, for example, professionals often rely on these tools for quick cuts on copper or PVC pipes during installations or repairs. Similarly, HVAC technicians utilize tube cutters for precise cuts on metal ducts; this versatility makes them indispensable in any toolkit focused on iron tube cutting tasks.

Types of Handheld Pipe Cutters

These tools come in different models designed specifically for steel and iron, ensuring that you have the right equipment for any job. Whether you're working on plumbing, HVAC systems, or metal fabrication, knowing your options can make all the difference.

Different Models for Steel and Iron

There are distinct models of pipe cutters tailored for cutting iron pipe and steel pipe effectively. For instance, a typical steel pipe cutter features hardened wheels that grip and slice through tough materials with ease, while an iron tube cutting model may emphasize durability to withstand heavy-duty use. When shopping at places like Home Depot or other tool suppliers, you'll find a variety of options ranging from simple manual cutters to more advanced powered versions.

In addition to traditional handheld models, some manufacturers offer specialized tube cutters designed specifically for tight spaces or intricate cuts in confined areas. These tools often feature a compact design and can be operated with one hand, making them ideal when you're juggling multiple tasks on-site. Choosing the right model ensures that you get the best performance whether you're cutting steel pipes or tackling cast iron projects.

Features of a Cast Iron Pipe Cutter

A cast iron pipe cutter boasts unique features tailored to tackle the challenges posed by thicker materials like cast iron pipes. One notable characteristic is its robust construction; these cutters are built to endure high levels of stress without bending or breaking during operation. Additionally, they often include adjustable cutting wheels that allow users to customize their approach based on the specific thickness of the material being cut.

Another important feature is their ability to provide clean cuts with minimal effort—essential when working on projects where precision matters most. Many cast iron pipe cutters also come equipped with ergonomic handles that enhance comfort during extended use while reducing fatigue—a must-have for professionals who spend hours on their feet! With these features combined, a quality cast iron pipe cutter becomes an invaluable asset in any toolbox.

Comparing Steel Pipe Cutters and Tube Cutters

When comparing steel pipe cutters and tube cutters, it's crucial to understand their distinct functionalities and applications in various settings. Steel pipe cutters typically excel at slicing through thicker materials due to their strong build and efficient cutting mechanisms; they're perfect for construction jobs or industrial applications requiring durability and strength during cutting operations. On the other hand, tube cutters shine in scenarios where precision is key—especially when dealing with thinner-walled tubing used in plumbing or HVAC installations.

While both tools serve essential purposes in metalworking environments, choosing between them depends largely on your specific project needs: if you’re focused on heavy-duty tasks involving thick steel pipes or casting work like cutting iron pipes regularly, opt for a robust steel pipe cutter; however if you need finesse over brute force—like when performing delicate work with thin tubes—a dedicated tube cutter would be your best bet! Understanding these differences will help you make informed decisions about which type of handheld cutter aligns best with your requirements.

How to Choose the Right Pipe Cutting Tool

Choosing the right pipe cutting tool is crucial for achieving clean, efficient cuts in various materials like steel and cast iron. With a plethora of options available, it can be overwhelming to decide which pipe cutter or tube cutter fits your needs best. By understanding key factors and essential features, you can make an informed decision that enhances your cutting experience.

Factors to Consider When Selecting a Cutter

When selecting a pipe cutter, first consider the type of material you’ll be working with—whether it’s steel or cast iron. Different materials require different cutting approaches; for instance, a steel pipe cutter may not perform well on thicker cast iron pipes. Additionally, think about the size and diameter of the pipes you’ll be cutting; some cutters are designed specifically for larger diameters while others excel in tight spaces.

Another factor is whether you need portability or stationary use. Handheld options are great for on-the-go jobs, while more robust models might be better suited for workshop settings. Lastly, consider your budget; high-quality tools often come at a premium but investing in a reliable pipe cutting tool can save you time and effort in the long run.

Essential Features for Efficiency

Efficiency hinges on several essential features that make a pipe cutter stand out from its competitors. Look for adjustable cutting wheels that allow you to customize depth based on material thickness; this feature is particularly beneficial when working with various types of iron tube cutting tasks. Ergonomics also play a vital role—choose a model with comfortable grips to reduce hand fatigue during extended use.

Another critical feature is durability; stainless steel components can significantly enhance longevity and performance under tough conditions. Additionally, consider cutters with built-in deburring capabilities to eliminate sharp edges after cutting—this saves time and enhances safety during handling. Ultimately, having an efficient tool will streamline your workflow whether you're using it as a home depot solution or in professional environments.

Top Brands and Where to Buy

When it comes to purchasing reliable pipe cutters or tube cutters, certain brands consistently stand out in terms of quality and performance. Renowned names like Ridgid, Milwaukee, and Dewalt offer an array of options suitable for both casual users and professionals alike—ensuring there's something for everyone from DIY enthusiasts to seasoned welders needing heavy-duty cast iron pipe cutters.

You can find these trusted brands at major retailers such as Home Depot or specialized online platforms dedicated to tools and machinery supplies. Be sure to read reviews before making your purchase; real-world feedback can provide valuable insights into how well each model performs under different conditions like cutting iron pipes versus steel pipes. Investing in reputable brands ensures you're equipped with tools that deliver results every time.

Best Practices for Cutting Iron and Steel Pipes

Cutting iron and steel pipes can be a straightforward task if you follow the right practices. Utilizing a reliable pipe cutter or tube cutter not only enhances efficiency but also ensures safety and precision in your work. Here are some best practices to consider for optimal results.

Safety First: How to Cut Pipes Safely

Safety should always be your top priority when engaging in any form of pipe cutting, especially with materials like cast iron or steel. Always wear appropriate personal protective equipment (PPE), including goggles, gloves, and ear protection, to safeguard against metal shards and loud noises. Additionally, ensure that your workspace is clean and organized; a clutter-free environment reduces the risk of accidents while using tools like pipe cutters from Home Depot or specialized steel pipe cutters.

Before you start cutting iron pipes, double-check that your chosen pipe cutter is in good condition—sharp blades are essential for safe operation. If you're using a power tool for tube cutting, make sure it’s well-maintained and that you understand how to operate it safely. Lastly, always secure the pipe properly before cutting; this prevents movement that could lead to injury or an uneven cut.

Tips for Achieving Clean Cuts Every Time

Achieving clean cuts when working with iron or steel requires more than just the right tools; technique plays a crucial role as well. Start by marking your cut line clearly on the pipe; this ensures precision as you guide your pipe cutter along the desired path. When using a cast iron pipe cutter or any other type of pipe cutting tool, apply even pressure throughout the cut to prevent jagged edges.

For those tackling thicker materials like steel pipes, consider making multiple passes with lighter pressure instead of trying to cut through in one go—this reduces stress on both the material and your tool. After completing the cut, use a deburring tool to smooth out any rough edges left behind; this not only enhances safety but also improves fitment when joining pipes together later on.

Maintenance Tips for Longevity

To get the most out of your pipe cutting tools—whether it's an iron tube cutting device or a specialized tube cutter—it’s vital to keep them well-maintained. Regularly inspect blades for dullness or damage; replacing worn-out parts promptly can save you time and ensure cleaner cuts every time you use them. For instance, if you're using a steel pipe cutter frequently, consider investing in high-quality replacement blades that can withstand rigorous use.

Additionally, clean your tools after each use by removing any debris or metal shavings that may have accumulated during cutting sessions; this helps prevent rusting and prolongs their lifespan significantly. Store your cutters in a dry place away from moisture—this is particularly important for cast iron cutters which can rust quickly if not cared for properly.

Lastly, don’t hesitate to refer back to manufacturer guidelines regarding maintenance procedures specific to each type of cutter; these recommendations often provide valuable insights into keeping your equipment in top shape over time.

Kiant Machinery: Your Go-To for Pipe Cutting Solutions

When it comes to pipe cutting solutions, Kiant Machinery stands out as a leader in the industry. They offer an extensive range of products, including specialized tools designed for both iron and steel pipe cutting. Whether you need a reliable cast iron pipe cutter or a versatile tube cutter, Kiant Machinery has you covered with innovative designs that enhance efficiency and precision.

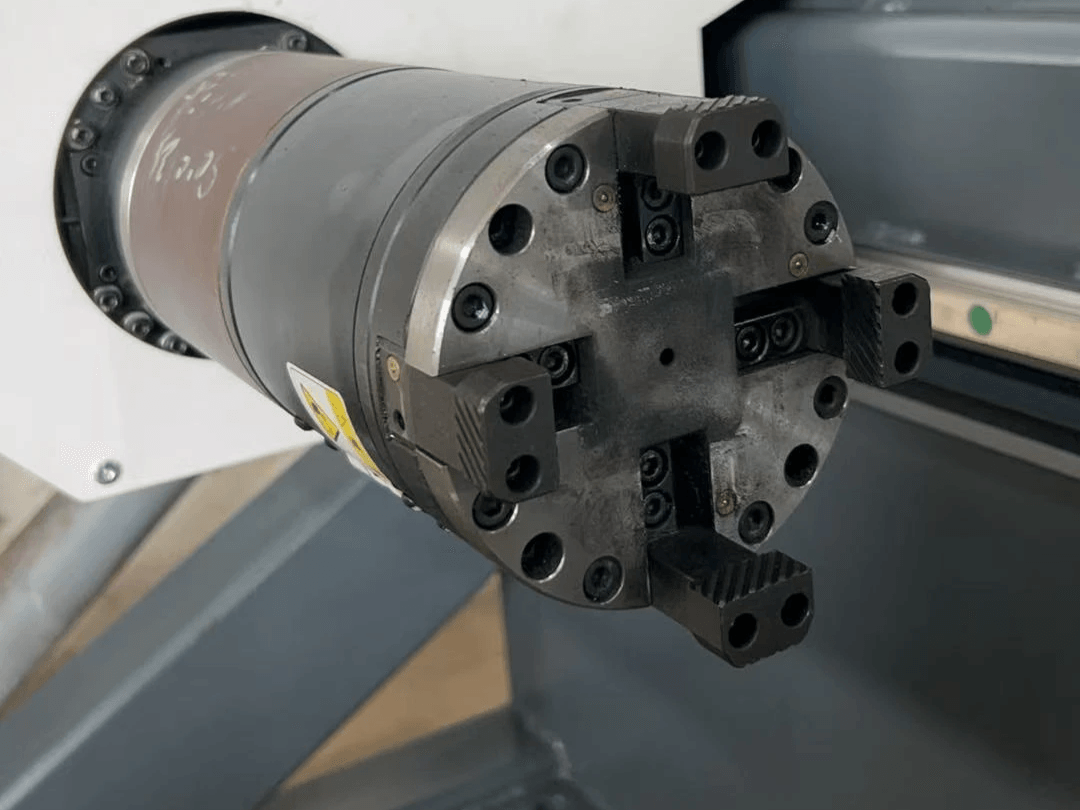

Overview of Kiant Machinery’s Products

Kiant Machinery's product lineup features an impressive array of pipe cutting tools tailored to meet various needs in metal fabrication. From heavy-duty steel pipe cutters to lightweight handheld options ideal for home use, their offerings cater to professionals and DIY enthusiasts alike. Their commitment to quality ensures that every tool, including their advanced laser tube cutting equipment, delivers exceptional performance and durability.

Benefits of Their Laser Tube Cutting Equipment

One standout feature of Kiant Machinery is their state-of-the-art laser tube cutting equipment which revolutionizes the way professionals approach iron tube cutting tasks. This technology not only provides precise cuts but also significantly reduces material waste compared to traditional methods like using a standard pipe cutter from Home Depot. The speed and accuracy offered by these machines allow users to maximize productivity while achieving clean cuts on various materials, including both steel and cast iron pipes.

Support and Training for Optimal Performance

Kiant Machinery understands that purchasing high-quality tools is just the beginning; proper support and training are essential for optimal performance. They provide comprehensive training programs designed to help users master their equipment, ensuring safe practices when using any type of pipe cutting tool, whether it's a steel pipe cutter or a more specialized model like the cast iron pipe cutter. With dedicated customer service ready to assist with any queries or technical issues, Kiant Machinery makes sure you're not just equipped but also empowered.

Conclusion

In the ever-evolving world of metal fabrication, investing in the right tools is paramount. Handheld pipe cutting machines, especially specialized ones like the cast iron pipe cutter or steel pipe cutter, are not just tools; they are gateways to efficiency and precision. As industries continue to grow and diversify, the importance of reliable pipe cutting tools cannot be overstated.

The Best Investment for Metal Fabrication

These cutting tools not only enhance performance but also save time and reduce waste during projects involving iron tube cutting or other materials. Whether you're a DIY enthusiast or a professional in the field, selecting a dependable tube cutter ensures that you tackle any job with confidence.

Enhancing Productivity with the Right Tools

Utilizing an efficient pipe cutting tool can significantly boost productivity on any job site or workshop floor. By opting for advanced models available at places like Pipe Cutter Home Depot, users can achieve clean cuts in less time than traditional methods allow. Moreover, having the right equipment means fewer interruptions and more streamlined workflows when cutting iron pipes or working with steel.

Future Trends in Pipe Cutting Technology

The future of pipe cutting technology looks promising as innovations continue to emerge at breakneck speed. Expect advancements such as automated systems and improved laser tube cutters that will redefine how we approach tasks like iron tube cutting and beyond. As these trends develop, staying ahead of the curve by investing in top-notch equipment will ensure that businesses remain competitive in an ever-changing landscape.