Introduction

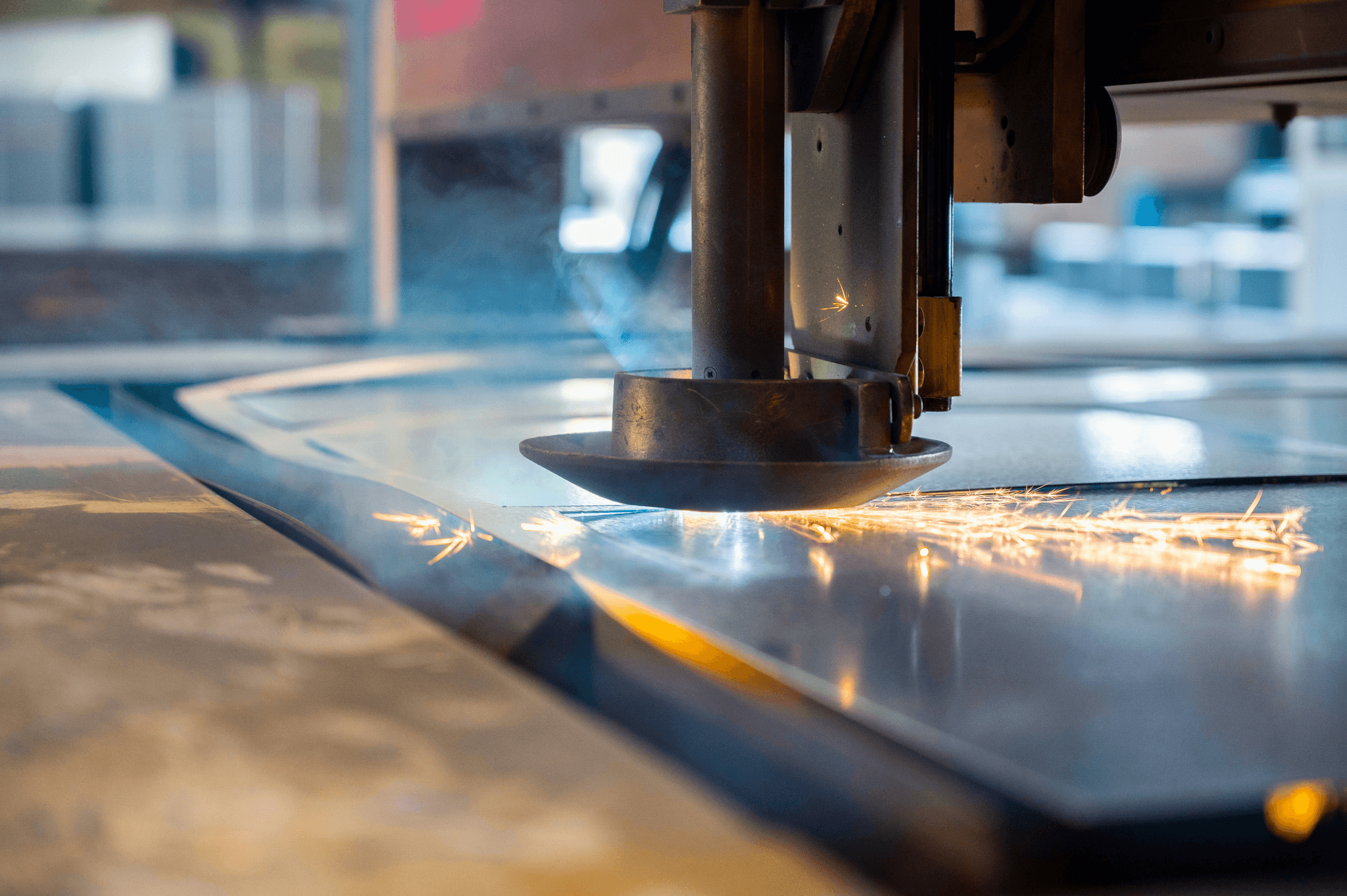

In the world of manufacturing, precision and efficiency are paramount, and that's where a metal laser cutting machine comes into play. These advanced machines utilize focused laser beams to cut through various types of metal with remarkable accuracy, making them indispensable for businesses that prioritize quality in their production processes. Understanding the intricacies of these machines is essential for anyone looking to invest in a metal cutting machine laser that meets their specific needs.

Choosing the right equipment can make or break your production capabilities. With a myriad of options available—from fiber laser cutting machines to traditional CO2 lasers—making an informed decision is crucial for maximizing productivity and minimizing costs. This guide will delve into the key considerations you should keep in mind when selecting your ideal laser machinery.

Before diving into the specifics, it's vital to assess your unique business needs. Factors such as production volume, material types, and desired cutting precision will heavily influence which type of laser machine is best suited for your operations. By understanding these elements upfront, you can streamline your search for the perfect fiber laser cutter or other types of laser machinery that align with your goals.

Assess Your Business Needs

The right laser machinery will not only enhance productivity but also ensure that you get the most out of your investment. A thorough assessment will help you pinpoint the specific requirements that align with your operational goals.

Evaluate Production Volume Requirements

First and foremost, consider how much work you expect to handle on a daily, weekly, or monthly basis. If you're running a high-volume operation, opting for a robust fiber laser cutting machine may be your best bet; these machines excel at speed and efficiency. On the other hand, if you're just starting out or have lower production demands, a more compact metal cutting machine laser could suffice.

Understanding production volume helps you choose between different models and configurations of laser machines. For instance, a fiber laser cutter designed for heavy-duty tasks might come with features that cater specifically to high throughput needs. Thus, evaluating your production volume requirements lays the groundwork for selecting the right equipment.

Identify Material Types and Thickness

Next up is identifying the types of materials you'll be working with and their respective thicknesses—this is pivotal when selecting a laser cutting machine. Different materials require different power levels and settings; for example, stainless steel may need more wattage than aluminum or acrylic. Therefore, knowing whether you'll be primarily handling sheet metal or thicker plates can influence your choice of machinery significantly.

A fiber laser machine typically offers versatility in material compatibility while maintaining precision across various thicknesses. If your projects often involve mixed materials or varying thicknesses, look for features that allow easy adjustments to settings without compromising on quality. This knowledge ensures that whatever metal cutting machine laser you choose will meet all your operational demands without unnecessary hiccups.

Determine Desired Cutting Precision

Finally, let's talk precision—arguably one of the most critical factors when selecting any type of laser machinery! Depending on your industry standards and customer expectations, you'll want to determine how precise cuts need to be for each project type. For applications requiring intricate designs or tight tolerances, investing in a high-precision fiber laser cutter could make all the difference in achieving top-notch results.

Precision also ties back into material types; thicker materials may require different techniques compared to thinner ones when aiming for accuracy in cuts. As such, understanding how much precision matters in your operations can guide you toward selecting features like advanced optics or motion control systems within the chosen metal laser cutting machine model. Ultimately, determining desired cutting precision ensures that every piece produced meets quality standards while maximizing efficiency.

Explore Different Types of Laser Machines

The market offers a range of options tailored to different needs, including fiber laser cutting machines, CO2 lasers, and hybrid systems. Each type has its unique advantages that can significantly impact your production efficiency and quality.

Fiber Laser Cutting Machines Explained

Fiber laser cutting machines have surged in popularity due to their exceptional efficiency and versatility. These machines utilize a solid-state laser source that generates high-intensity light beams, allowing for precise cuts on various metal materials with ease. A fiber laser cutter is particularly effective for thin to medium thickness metals, making it an ideal choice for industries that require intricate designs and high-speed processing.

One of the standout features of fiber laser machinery is its lower operational costs compared to traditional CO2 systems. This is largely because fiber lasers consume less energy while delivering superior cutting speeds and precision. Additionally, their maintenance requirements are minimal, which translates into reduced downtime and increased productivity for your business.

CO2 vs. Fiber Laser: What's Best for You?

When comparing CO2 lasers with fiber laser machines, it's essential to consider the specific applications you have in mind. CO2 lasers excel at cutting non-metal materials like wood or acrylic but may fall short when tackling thicker metals compared to fiber laser systems. If your focus is primarily on metal fabrication or working with reflective materials like aluminum or copper, a metal cutting machine laser based on fiber technology will likely serve you better.

However, if you're operating in a diverse environment where both metal and non-metal materials are processed regularly, investing in a dual-purpose system might be worth considering. Understanding your material types and thicknesses will help narrow down whether a CO2 or fiber solution aligns best with your operational goals. Ultimately, assessing these factors will ensure you choose the right laser machinery tailored to your production needs.

Understanding Hybrid Laser Machinery

Hybrid laser machinery combines the strengths of both CO2 and fiber technologies into one versatile platform. This innovative approach allows users to cut through various materials without needing multiple machines dedicated solely to one type of material or application—talk about efficiency! With hybrid systems gaining traction in modern manufacturing environments, they offer flexibility that can adapt as production demands shift over time.

These machines typically feature interchangeable heads that can switch between CO2 and fiber settings depending on the material being processed. As such, they provide unparalleled versatility for businesses looking to diversify their product offerings without investing heavily in multiple standalone systems. If you're looking for adaptability alongside robust performance from your metal laser cutting machine investments, hybrid options could be just what you need!

Consider Power and Performance

The wattage of the laser directly influences its cutting capabilities, speed, and efficiency. Understanding how these elements interplay can significantly enhance your decision-making process when investing in a laser machine.

Importance of Laser Wattage

Laser wattage is essentially the powerhouse behind your fiber laser cutting machine's effectiveness. Higher wattage typically translates to faster cutting speeds and the ability to handle thicker materials with ease. If you're aiming for high productivity and versatility in your projects, opting for a metal laser cutting machine with sufficient wattage is crucial to meet those demands.

Balancing Speed and Cutting Quality

While speed is often an appealing factor when choosing a laser machinery option, it shouldn't come at the cost of cutting quality. A well-calibrated fiber laser cutter should strike an ideal balance between swift operation and precision cuts. Investing in a reliable laser cutting machine ensures that you achieve both efficiency and exceptional results without sacrificing one for the other.

How Power Impacts Material Thickness

The power output of your chosen laser machine significantly affects its ability to cut through various material thicknesses effectively. Generally, higher wattage allows for more substantial cuts in thicker metals, making it essential to match your fiber laser machine's power with your specific material requirements. Understanding this relationship will help you select a metal cutting machine that meets both your current needs and future growth potential.

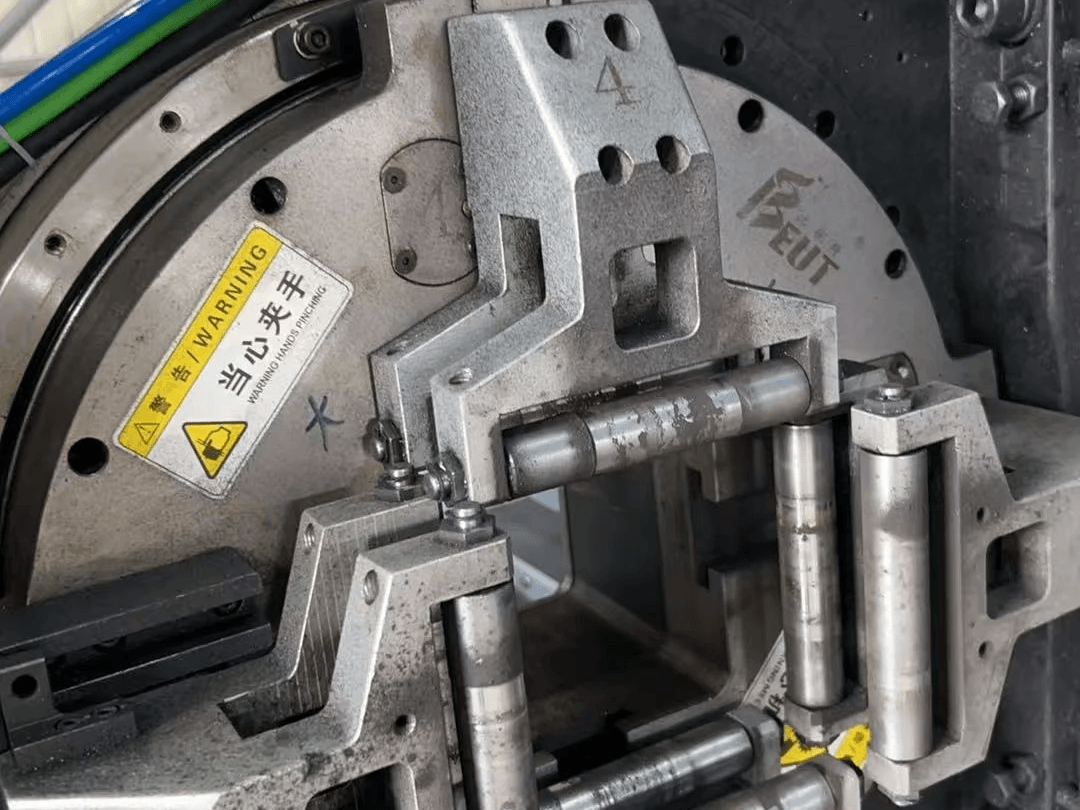

Look at the Machine's Build Quality

When investing in a metal laser cutting machine, the build quality is paramount. A robust design not only ensures longevity but also enhances overall performance during cutting operations. Choosing a well-constructed laser machine can prevent costly downtime and maintenance issues, making it an essential factor in your selection process.

Assessing Durability and Design

Durability is a critical aspect of any metal cutting machine laser; it directly impacts how well the equipment can withstand the rigors of daily use. Look for machines made from high-quality materials that resist wear and tear, especially if you plan to cut various types of metals frequently. Additionally, an ergonomic design can enhance usability, making your workflow smoother and more efficient.

Importance of Manufacturer Reputation

The reputation of the manufacturer plays a significant role in ensuring you get a reliable laser machinery solution. Established brands usually have proven track records for producing high-quality fiber laser cutters that stand the test of time. Researching customer reviews and testimonials will give you insights into how manufacturers support their products post-purchase.

Features of Reliable Laser Machinery

Reliable laser machinery comes equipped with features that enhance both performance and ease of use. Look for advanced cooling systems to maintain optimal operating temperatures, as well as safety features that protect operators during cutting processes. Furthermore, consider machines with modular components; this flexibility allows for easier upgrades down the line without needing to replace your entire fiber laser machine.

Evaluate Software Compatibility

In the world of metal laser cutting machines, software compatibility is a crucial consideration that can make or break your operational efficiency. The right software can enhance the capabilities of your laser cutting machine, allowing you to achieve optimal results with minimal hassle. Therefore, understanding the nuances of software integration is essential for anyone looking to invest in a metal cutting machine laser.

User-Friendly Interfaces

A straightforward interface allows operators to navigate functions easily without extensive training, which is essential in busy manufacturing environments. Look for a laser machine that offers intuitive controls and clear displays; this will save time and reduce errors during operation.

Additionally, an easy-to-use interface can significantly decrease the learning curve for new employees who will be using the fiber laser cutter or other models. If your team can quickly adapt to the system, you'll see immediate benefits in terms of efficiency and output quality. After all, who wants to spend hours deciphering complicated menus when they could be cutting metal instead?

Importance of CAD/CAM Software Integration

The integration of CAD/CAM software with your metal laser cutting machine is another pivotal factor that shouldn’t be overlooked. Effective CAD/CAM software allows for seamless design-to-production workflows, enabling you to translate intricate designs into precise cuts effortlessly on your fiber laser machine. This means less time spent on manual adjustments and more time focusing on creating high-quality products.

Moreover, having robust CAD/CAM capabilities ensures that you can work with various file formats and make quick modifications as needed—essential features for any modern metal cutting machine laser user. The ability to customize designs directly within the software streamlines operations and enhances overall productivity while minimizing potential errors during production runs.

Customization and Automation Options

Customization options are vital when evaluating potential laser machinery because they allow businesses to tailor their equipment according to specific needs or projects. A versatile fiber laser cutter should offer adjustable settings that cater not just to different materials but also varying thicknesses—ensuring maximum flexibility in production processes. This adaptability helps businesses stay competitive by efficiently handling diverse projects without requiring multiple machines.

Automation features further enhance these capabilities by reducing manual labor requirements and increasing consistency across batches of products produced by your metal cutting machine laser. Automated systems can manage everything from loading materials to executing intricate cut patterns with precision—freeing up operators for other critical tasks while ensuring that quality remains uncompromised throughout production runs.

In summary, evaluating software compatibility is fundamental when selecting a fiber laser machine or any other type of metal laser cutting equipment. By ensuring user-friendly interfaces, robust CAD/CAM integration, and ample customization options paired with automation capabilities, you’ll set yourself up for success in today’s fast-paced manufacturing landscape.

Factor in Maintenance and Support

When investing in a metal laser cutting machine, it’s crucial to consider the ongoing maintenance and support that will keep your laser machinery running smoothly. Regular upkeep is essential to ensure optimal performance, longevity, and precision cutting capabilities of your fiber laser cutter. A well-maintained machine not only enhances productivity but also reduces unexpected downtime, which can be costly for any business.

Regular Maintenance Needs

Every metal cutting machine laser requires a certain level of regular maintenance to function at its best. This includes routine checks on components like the lens, mirrors, and cooling systems, as well as maintaining proper alignment for accurate cuts with your fiber laser machine. If you neglect these tasks, you could face decreased efficiency or even damage that might necessitate costly repairs or replacements.

To avoid these pitfalls, establish a maintenance schedule tailored to your specific model of laser cutting machine. Consult the manufacturer’s guidelines for recommended practices and frequency; this will help you stay ahead of potential issues before they escalate into major problems. Keeping up with regular maintenance not only ensures the longevity of your equipment but also maximizes the return on investment (ROI) from your fiber laser cutter.

Importance of Manufacturer Support

When things go awry with your laser machinery, having reliable manufacturer support can make all the difference between a minor hiccup and a full-blown crisis. Good manufacturers provide comprehensive technical support to help troubleshoot issues quickly—after all, every minute spent sidelined is money lost for your business operating a metal cutting machine laser. Look for companies known for their responsive customer service; this will give you peace of mind knowing expert assistance is just a call away.

Additionally, some manufacturers offer extended warranties or service agreements that cover parts and labor for repairs—this can be invaluable when unforeseen problems arise with your fiber laser cutting machine. It’s worth investigating what kind of post-purchase support is available before making a commitment; after all, you'll want to feel secure in your investment long after you've made it.

Training and Resources: Are They Included?

A top-notch metal laser cutting machine often comes bundled with training resources designed to get you up and running efficiently from day one. Many manufacturers provide comprehensive training programs that cover everything from basic operation to advanced troubleshooting techniques tailored specifically for their models of fiber laser machines. This investment in training can significantly reduce errors during initial use and improve overall productivity.

Moreover, consider whether there are additional resources available such as online tutorials or user manuals that can help enhance operator skills over time—this knowledge can be crucial when dealing with complex projects involving various materials and thicknesses using the laser cutting machine technology. Investing in training ensures that both new hires and seasoned professionals are equipped with the necessary skills to maximize the capabilities of their metal cutting machines.

Compare Costs and ROI

When it comes to investing in a metal laser cutting machine, understanding the financial implications is crucial. The initial investment can be significant, but it's essential to weigh this against the long-term savings that a quality laser cutting machine can provide. A well-chosen laser machine can streamline operations, reduce waste, and ultimately enhance profitability over time.

Initial Investment vs. Long-Term Savings

Purchasing a high-quality fiber laser cutting machine often requires a considerable upfront cost, but the benefits can far outweigh this initial expense. Investing in a durable and efficient metal cutting machine laser means you’ll likely experience lower operational costs due to reduced energy consumption and less material wastage. Over time, these savings can accumulate significantly, making your choice of equipment not just an expense but a strategic investment for your business.

Hidden Costs to Consider

While evaluating the costs associated with a laser cutting machine, it's important to consider hidden expenses that may arise over time. Maintenance costs for parts like lenses or mirrors in your fiber laser cutter can add up if not factored into your budget from the start. Additionally, software licensing fees or potential upgrades for automation features on your laser machinery could impact overall expenditure—so keep an eye on those fine print details!

How to Calculate Your Return on Investment

Calculating the return on investment (ROI) for your new metal laser cutting machine involves assessing both direct and indirect benefits over time. Start by estimating how much money you'll save through improved efficiency and reduced waste compared to previous methods of metal cutting. Then factor in any additional revenue generated from increased production capabilities or new projects made possible by investing in advanced technology like fiber laser machines—this holistic approach will give you a clearer picture of how profitable your investment will truly be.

Conclusion

In the fast-paced world of manufacturing, selecting the right metal laser cutting machine is crucial for optimizing efficiency and quality. With various options available, understanding your specific needs and the capabilities of different laser machinery can make all the difference. By weighing factors such as production volume, material types, and desired precision, you can ensure that your investment pays off in the long run.

Key Takeaways for Smart Selection

When it comes to choosing a metal cutting machine laser, clarity is key. First, assess your business needs by evaluating production volume requirements and material specifications; this will guide you towards the right type of fiber laser cutting machine or other options that suit your operations best. Additionally, consider power and performance—higher wattage often translates to better cutting capabilities but must be balanced with speed and quality.

Another important aspect is build quality; a durable laser machine from a reputable manufacturer will likely provide better longevity and performance over time. Don’t forget about software compatibility—user-friendly interfaces paired with robust CAD/CAM integration can streamline operations significantly. Finally, factor in maintenance needs and support options to ensure smooth sailing post-purchase.

Questions to Ask Before Buying

Before making a leap into purchasing a laser cutting machine, ask yourself some critical questions to avoid buyer's remorse later on. What are my specific production goals? Understanding whether you need high-volume output or precision cuts will help narrow down choices between fiber laser machines or hybrid models.

Also consider: what materials do I plan to cut? Different machines excel with various thicknesses and types of metals; knowing this upfront can steer you toward the ideal fiber laser cutter for your needs. Lastly, inquire about after-sales support—what kind of training resources does the manufacturer offer? This could save you time and headaches down the line.

Choosing Kiant Machinery for Your Needs

When it comes to investing in a reliable metal laser cutting machine, Kiant Machinery stands out as a top contender in the industry. Their diverse range of products includes advanced fiber laser machines designed for various applications without compromising on quality or performance. Plus, their commitment to customer support ensures that you're never left hanging after your purchase.

Kiant’s reputation speaks volumes; they have built trust among users with their durable designs and innovative technology tailored specifically for modern manufacturing demands. With user-friendly software integration options available alongside comprehensive training resources, selecting Kiant means you're equipping yourself with not just machinery but also invaluable knowledge for optimal usage. Make an informed choice today!