Introduction

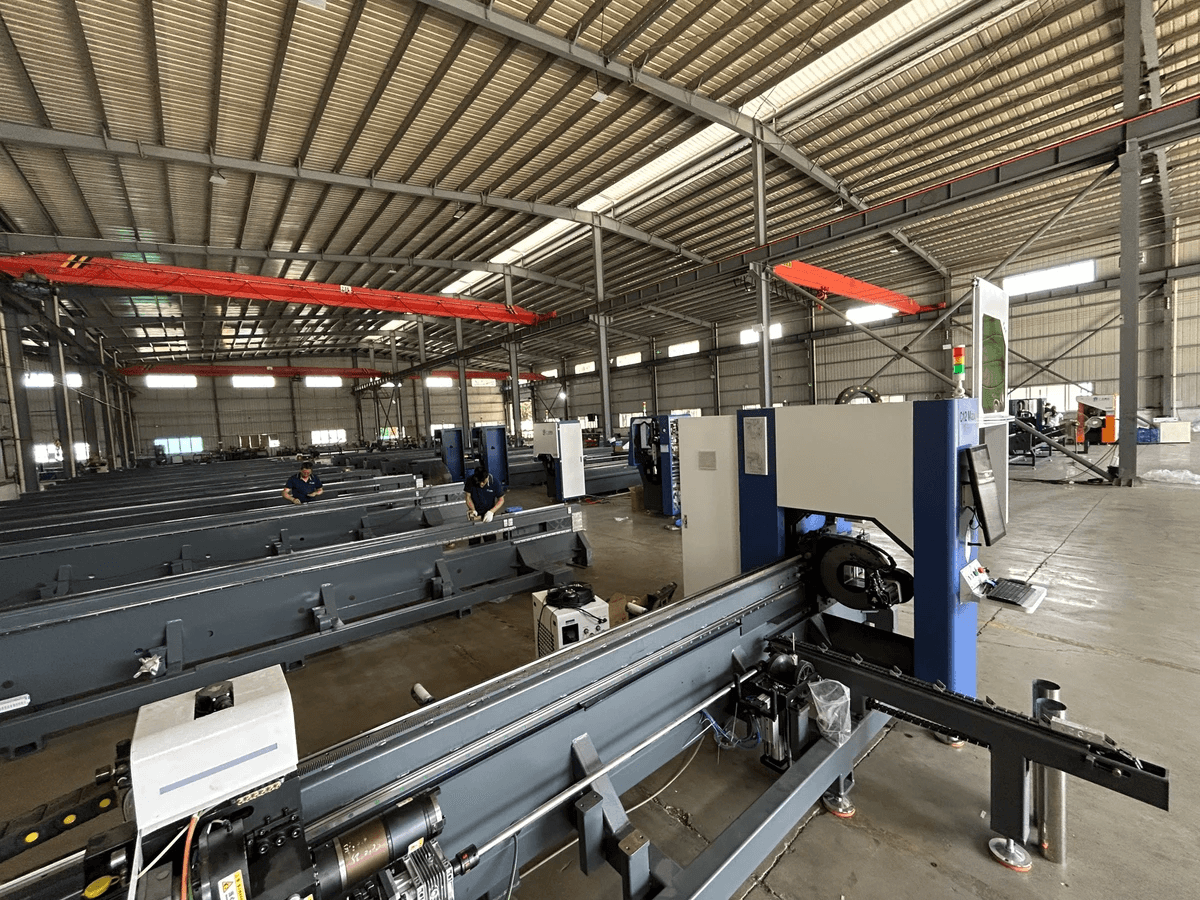

Welcome to the world of Kiant Machinery, where innovation meets precision in the realm of metal processing. Our expertise in laser cutting services sets us apart, making us a leader in providing top-notch solutions tailored to your needs. With our advanced technology and commitment to quality, we ensure that every project is executed with utmost care and efficiency.

Explore Kiant Machinery's Expertise

At Kiant Machinery, we pride ourselves on our extensive knowledge and experience in laser cutting technology. Our team of skilled professionals is dedicated to delivering exceptional results using state-of-the-art metal cutting machine lasers. From design to execution, we harness our expertise to provide unparalleled laser cutting services that meet diverse industry demands.

Understanding Laser Cutting Services

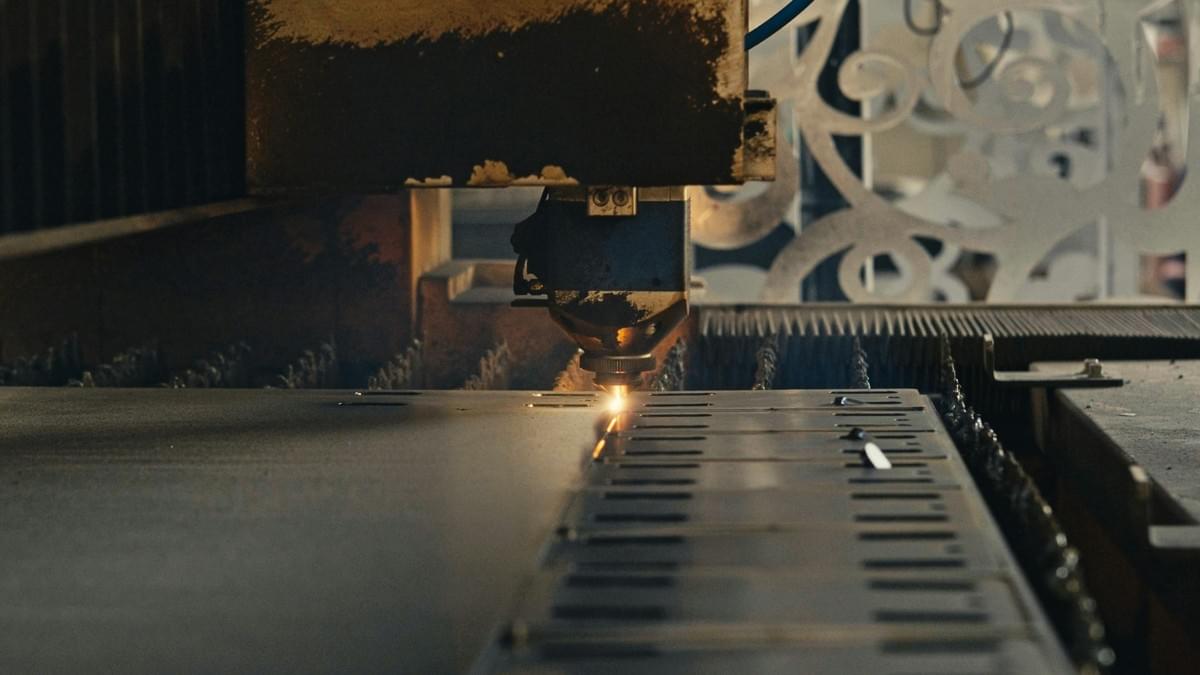

Laser cutting is a revolutionary process that utilizes focused beams of light to cut through various materials with remarkable accuracy. This technique has transformed the way industries approach manufacturing and fabrication, offering a level of precision that traditional methods simply cannot match. By employing advanced laser machines, businesses can achieve intricate designs while minimizing waste and maximizing efficiency.

The Importance of Metal Cutting

Metal cutting is a critical component across numerous sectors, from automotive to aerospace and beyond. The ability to precisely cut metal not only enhances production capabilities but also plays a vital role in ensuring product quality and durability. With our specialized metal laser cutting service, you can trust that your projects will benefit from superior craftsmanship and innovative technology.

What is Laser Cutting Service?

Laser cutting service is a transformative technology that utilizes focused laser beams to cut through various materials with incredible precision. This method has revolutionized the way industries approach metal cutting, offering a clean and efficient alternative to traditional methods. By harnessing the power of a cutting machine laser, businesses can achieve intricate designs and high-quality finishes that were once difficult to attain.

Definition and Process Overview

At its core, laser cutting involves directing a high-powered laser beam onto a material surface, which melts or vaporizes the material along a predetermined path. The process begins with the design of the desired shape using computer-aided design (CAD) software, which then guides the metal cutting machine laser during operation. This level of automation not only enhances accuracy but also significantly reduces waste compared to manual methods.

The versatility of laser machines allows them to cut through various materials such as metals, plastics, and wood, making them indispensable in manufacturing processes across multiple sectors. Additionally, because the process produces minimal heat-affected zones, it preserves the integrity of surrounding materials and reduces post-processing requirements. Thus, understanding this innovative technology is essential for anyone looking into effective metal laser cutting service options.

Advantages of Using a Laser Machine

One of the standout advantages of using a laser machine for metal cutting is its unmatched precision and accuracy. Unlike traditional cutting methods that may leave rough edges or require extensive finishing work, laser cutting delivers clean cuts with smooth edges every time. This precision not only enhances aesthetic appeal but also ensures that components fit together perfectly in assembly applications.

Another significant benefit is speed; laser cutting machines operate at impressive speeds without sacrificing quality or detail in their cuts. This efficiency translates into faster production times and lower operational costs for businesses looking to optimize their manufacturing processes. Furthermore, since these machines can be programmed for various tasks without needing physical adjustments or tool changes, they offer remarkable flexibility in production runs.

Cost-effectiveness is yet another reason why many industries are turning to metal cutting machine lasers for their needs. While initial investments may seem high, reduced material waste combined with shorter lead times ultimately leads to significant savings over time. In essence, utilizing advanced technologies like those offered by Kiant Machinery can provide both short-term benefits and long-term value.

Applications Across Industries

Laser cutting services have found applications across an impressive range of industries due to their versatility and effectiveness in handling different materials and designs. In automotive manufacturing, for instance, precise cuts are crucial for producing lightweight components that contribute to fuel efficiency while maintaining structural integrity—something easily achieved with a reliable laser cutting machine.

The aerospace sector also benefits tremendously from this technology; complex geometries required for aircraft parts demand exacting standards that only advanced metal laser cutting services can fulfill effectively. Moreover, sectors like electronics rely on precise cuts in circuit boards where space constraints necessitate extreme accuracy—again highlighting how integral these machines have become across diverse fields.

Even beyond industrial applications, artistic endeavors such as custom signage creation or intricate art pieces showcase how creative professionals leverage these services for unique projects that stand out visually while maintaining structural strength through precise cuts made by advanced equipment like our state-of-the-art lasers at Kiant Machinery.

The Technology Behind Metal Cutting Machines

These machines utilize advanced laser technology to achieve precision cuts that are difficult to replicate with traditional methods. With a variety of options available, businesses can select the ideal cutting machine laser that suits their specific needs.

Types of Laser Cutting Machines

There are several types of laser cutting machines available on the market, each designed for particular applications and materials. The most common types include CO2 lasers, fiber lasers, and solid-state lasers. Each type offers unique advantages; for instance, fiber lasers excel in cutting reflective metals while CO2 lasers are often preferred for non-metal materials.

The choice of a laser machine can significantly impact the efficiency and quality of your metal laser cutting service. Factors such as material thickness and cutting speed should be considered when selecting a metal cutting machine laser. Understanding these various types helps businesses make informed decisions about which technology best aligns with their operational goals.

How Cutting Machines Laser Work

Cutting machines laser operate by focusing a high-powered beam onto the material being cut, creating intense heat that melts or vaporizes the material away. This process allows for intricate designs and precise cuts with minimal waste—a significant advantage over traditional cutting methods. The ability to automate this process further enhances efficiency while reducing labor costs associated with manual operations.

In addition to precision, these machines can be equipped with advanced software that optimizes the path of the laser beam for maximum effectiveness during operation. This means faster cycle times without compromising quality—an essential factor in today’s competitive manufacturing landscape. By leveraging state-of-the-art technology, businesses can streamline their production processes while ensuring superior results in their metal laser cutting service.

Innovations in Laser Cutting Technology

The world of laser cutting is continuously evolving with new innovations aimed at enhancing performance and capabilities. Recent advancements include improved beam quality and power efficiency that allow for faster speeds and cleaner cuts on thicker materials using a metal cutting machine laser. Additionally, developments in automation and AI-driven systems enable real-time monitoring and adjustments during operation.

Another exciting trend is the integration of 3D printing technologies with traditional laser cutting services, allowing manufacturers to create complex geometries that were previously unattainable. These innovations not only increase productivity but also broaden the range of applications across various industries—from aerospace to automotive manufacturing. Staying ahead in this fast-paced environment means embracing these technological advancements for optimal results.

Advantages of Kiant Machinery's Laser Solutions

Our cutting machine laser technology not only enhances precision but also boosts efficiency in metal cutting processes. With a commitment to quality and innovation, we ensure that our laser solutions meet the diverse needs of various industries.

High Efficiency and Precision

One of the hallmark features of our laser cutting machines is their remarkable efficiency. These machines are designed to execute intricate cuts with extreme precision, ensuring that every piece meets exact specifications without unnecessary waste. This high level of accuracy translates into reduced production times, allowing businesses to ramp up their output while maintaining top-notch quality in their metal laser cutting service.

Moreover, our metal cutting machine laser systems operate with minimal downtime, thanks to advanced technology that streamlines operations. By investing in our state-of-the-art equipment, you can expect not only faster turnaround times but also consistent results across all projects. In an industry where precision is paramount, choosing Kiant Machinery means opting for reliability and excellence.

Customization for Various Needs

At Kiant Machinery, we understand that one size does not fit all when it comes to laser cutting services. That's why we offer extensive customization options tailored specifically to your unique requirements. Whether you need specialized cuts or specific materials processed, our team works closely with you to develop a solution that fits your needs perfectly.

This flexibility extends beyond just the machinery; it encompasses the entire process from design through execution. Our engineers are adept at adapting our cutting machine laser technology to accommodate various applications and industries—from automotive parts to intricate art pieces. With such a personalized approach, clients can achieve results that align precisely with their vision.

Cost-Effectiveness of Our Services

Cost considerations are always top-of-mind for any business looking into metal laser cutting service options—and rightly so! At Kiant Machinery, we pride ourselves on offering cost-effective solutions without compromising on quality or performance. Our efficient processes reduce material waste and labor costs while maximizing output.

Additionally, by leveraging advanced technologies in our laser machines, we minimize energy consumption during operation, further driving down expenses for users over time. Investing in a metal cutting machine laser from us not only enhances productivity but also leads to significant savings in both short- and long-term operational costs. When you choose our services, you're not just getting exceptional quality; you're making a smart financial decision too!

The Role of Training and Support

At Kiant Machinery, we understand that selecting the appropriate equipment is just the beginning; proper installation and ongoing education are key to leveraging our advanced metal cutting machine laser technology. Our commitment to customer success goes beyond just providing a product; we ensure you have the knowledge and resources needed to thrive.

Equipment Selection and Installation

Choosing the right cutting machine laser can feel overwhelming, but our team at Kiant Machinery is here to simplify that process. We guide you through selecting a laser cutting machine that best fits your specific needs, whether you're focusing on high-volume production or intricate designs. Once you've made your choice, our experts will handle the installation with precision, ensuring your metal laser cutting service gets off to a flawless start.

Ongoing Training for Operators

Even the most sophisticated laser machines require skilled operators who know how to harness their full potential. That's why we provide comprehensive ongoing training tailored specifically for your team, ensuring they are well-versed in operating the latest metal cutting machine laser technology safely and efficiently. This continuous education not only enhances productivity but also fosters a culture of innovation within your organization.

After-Sales Support and Maintenance

Our relationship doesn't end once you've purchased a laser cutting machine; it's just the beginning! Kiant Machinery prides itself on offering robust after-sales support that includes regular maintenance checks and troubleshooting assistance for all our clients using our metal laser cutting service. With dedicated customer support at your fingertips, you can rest easy knowing that any issues will be swiftly addressed by our knowledgeable team.

Success Stories: Kiant Machinery in Action

At Kiant Machinery, we believe that actions speak louder than words. Our laser cutting service has transformed businesses across various industries, showcasing our commitment to precision and quality. Let’s dive into some of the remarkable success stories that highlight the impact of our metal laser cutting service.

Case Studies of Transformation

One notable case involved a local automotive parts manufacturer struggling with the inefficiencies of traditional metal cutting methods. After switching to our advanced laser cutting machine, they saw a 40% increase in production speed and a significant reduction in material waste. This transformation not only improved their bottom line but also allowed them to take on larger orders with confidence.

Another success story comes from an aerospace company that needed intricate designs for aircraft components. Utilizing our cutting machine laser technology, they achieved unparalleled precision and detail that was previously unattainable with conventional methods. The result? They enhanced their product offerings while ensuring compliance with stringent industry standards.

In yet another instance, a custom furniture maker faced challenges in meeting client specifications due to limitations in traditional cutting techniques. By adopting our state-of-the-art metal cutting machine laser, they could produce complex designs quickly and accurately, leading to increased customer satisfaction and repeat business. These case studies demonstrate how Kiant Machinery's laser solutions can revolutionize production processes across diverse sectors.

Customer Feedback and Testimonials

Our clients often express how transformative our laser cutting services have been for their operations. One satisfied customer remarked, Switching to Kiant's laser machine was a game-changer; it not only streamlined our workflow but also elevated the quality of our products. Such feedback reinforces the value we provide through innovative technology and dedicated support.

Another client shared their experience: The precision of the metal laser cutting service we received exceeded all expectations! We were able to reduce waste significantly while enhancing design capabilities. Testimonials like these highlight not just satisfaction but genuine excitement about how our machinery has positively impacted their businesses.

Feedback is vital for us at Kiant Machinery; it drives continuous improvement and innovation in our offerings. We take pride in building strong relationships with customers who feel empowered by the capabilities provided by our advanced laser cutting machines.

Long-Term Partnerships and Collaborations

Building long-term partnerships is at the heart of what we do at Kiant Machinery. Our commitment extends beyond merely providing a metal cutting machine laser; we aim to be integral partners in our clients' growth journeys. For instance, one partnership with an industrial manufacturer led to co-developing specialized applications tailored specifically for their needs using advanced laser technology.

Collaboration doesn’t stop at sales; we regularly engage with clients for feedback on new features or potential improvements on existing machines—ensuring that they receive maximum value from their investment in our services. This ongoing dialogue fosters loyalty and trust as clients see us as allies rather than just vendors.

As we look towards future innovations, these partnerships will be crucial for driving advancements in both technology and application within the realm of metal processing solutions like ours—proving once again that when you choose Kiant Machinery for your laser cutting needs, you're choosing more than just a service; you're choosing a partner committed to your success!

Conclusion

In wrapping up our exploration of Kiant Machinery's offerings, it's clear that when it comes to laser cutting service, we stand out in the market. Our commitment to quality and innovation in laser cutting technology ensures that your metal projects are handled with the utmost precision and efficiency. Choosing us means investing in a partnership that prioritizes your needs and drives your success.

Why Choose Kiant Machinery?

Kiant Machinery is synonymous with excellence in laser cutting solutions, providing top-tier metal cutting machine laser services tailored to various industries. Our state-of-the-art cutting machine laser technology guarantees high efficiency, allowing you to meet tight deadlines without compromising on quality. Moreover, our dedication to customization means we can adapt our laser cutting service to fit your unique specifications, ensuring optimal results every time.

The Future of Laser Cutting Technology

The future of laser cutting technology is bright and filled with potential innovations that will further enhance the capabilities of metal laser cutting service providers like us. As advancements continue to emerge, we anticipate even greater precision and speed from our laser machines, making them indispensable tools across all sectors. By staying ahead of these trends and incorporating new technologies into our services, Kiant Machinery positions itself as a leader in the ever-evolving landscape of metal cutting solutions.

Your Next Steps for Metal Laser Cutting Service

Ready to elevate your projects with superior metal laser cutting service? Start by reaching out to us for a consultation where we can discuss your specific needs and how our advanced laser cutting machines can meet them effectively. Whether you're looking for ongoing support or a one-time project execution, Kiant Machinery is here to guide you every step of the way.