Introduction

In the realm of modern manufacturing, the laser tube cutting machine has emerged as a game-changer. This technology combines precision and efficiency, allowing for intricate designs and clean cuts that traditional methods simply can't match. As industries evolve, understanding the capabilities and future potential of laser tube cutting is essential for staying competitive.

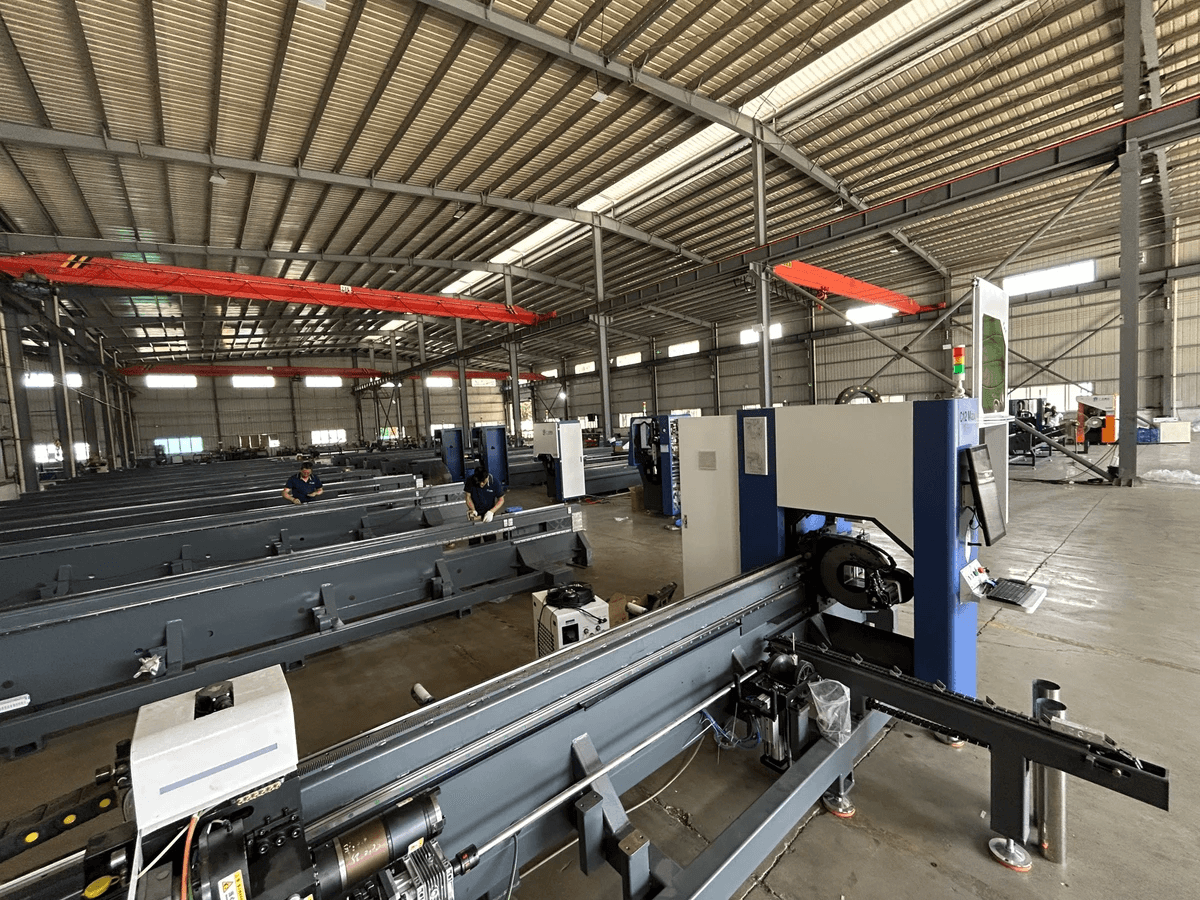

Overview of Laser Tube Cutting

Laser tube cutting involves using focused laser beams to slice through metal tubes with remarkable accuracy. This technique enables manufacturers to create complex shapes and patterns while minimizing waste material, which is crucial in today's cost-conscious market. With advancements in laser technology, users can now achieve faster processing times and higher quality finishes than ever before.

Advantages of Using a Laser Tube Cutting Machine

The advantages of employing a laser tube cutting machine are numerous and compelling. For starters, these machines offer unparalleled precision; even the most intricate designs can be executed flawlessly without compromising material integrity. Additionally, they reduce operational costs by minimizing material wastage and decreasing labor requirements—making it easier to answer questions like How much does a tube laser cost? with confidence in their long-term value.

The Future of Metal Cutting Technologies

As we look to the future, it's clear that innovations in metal cutting technologies will continue to shape industries across the globe. New developments promise increased capabilities such as improved thickness limits—prompting inquiries like How thick can a tube laser cut?—and longer-lasting equipment that raises questions about longevity: How long does a laser cutter tube last? The landscape of manufacturing is changing rapidly; those who embrace these advancements will undoubtedly lead the way.

What Is Laser Tube Cutting?

Laser tube cutting is a modern manufacturing process that utilizes focused laser beams to cut through various types of tubes and pipes. This precision technique allows for intricate designs and shapes that are difficult to achieve with traditional cutting methods. As industries evolve, the demand for efficient and accurate cutting solutions has made the laser tube cutting machine a go-to choice for many manufacturers.

Basic Principles of Laser Cutting

At its core, laser cutting involves directing a high-powered laser beam onto the material's surface, where it melts or vaporizes the material to create a clean cut. The process is highly controlled, allowing operators to adjust parameters like speed and power depending on the material type and thickness. This level of precision means that users often ask, How thick can a tube laser cut?—the answer varies based on machine specifications but typically ranges from thin sheets to several inches thick.

Different Types of Laser Tube Cutting Machines

There are several types of laser tube cutting machines available on the market, each designed for specific applications and materials. CO2 lasers are popular for non-metal materials while fiber lasers excel in metal processing due to their efficiency and speed. When considering What is the cost of a laser cutting machine?, it's essential to factor in not just the initial purchase price but also ongoing operational costs associated with different machine types.

Overview of Applications in Various Industries

Laser tube cutting finds extensive applications across multiple industries including automotive, aerospace, construction, and furniture manufacturing. Its ability to produce complex geometries makes it ideal for creating components such as exhaust systems or structural supports in buildings. As companies seek ways to enhance productivity while reducing waste, they often turn to this technology—prompting questions like How much does a tube laser cost? as they weigh their investment options against potential savings.

How Much Does a Tube Laser Cost?

When considering the purchase of a laser tube cutting machine, one of the most pressing questions is, How much does a tube laser cost? The price can vary significantly based on several factors, including the machine's capabilities, features, and brand reputation. Understanding these influences is crucial for businesses looking to invest wisely in their manufacturing processes.

Factors Influencing Laser Tube Pricing

The cost of a laser tube cutting machine is influenced by multiple factors that can make or break your budget. First off, the type and quality of the laser technology used play a significant role; fiber lasers tend to be more expensive but offer superior cutting speed and precision compared to CO2 lasers. Additionally, features such as automation capabilities, software integration, and customization options will also impact pricing; more advanced machines typically come with higher costs.

Moreover, brand reputation cannot be overlooked when discussing how much a tube laser costs. Established manufacturers may charge more due to their proven track record and customer support services. Lastly, market demand and technological advancements can lead to fluctuations in pricing; as new innovations emerge, older models may become more affordable while still providing excellent performance.

Cost Comparison with Traditional Cutting Methods

When you stack up the cost of laser tube cutting machines against traditional cutting methods like plasma or mechanical saws, it becomes clear that there are pros and cons to each approach. Traditional methods often have lower upfront costs but can lead to higher operational expenses over time due to inefficiencies and increased material waste. In contrast, while investing in a laser cutter might seem steep initially—especially when pondering What is the cost of laser cutting machine?—the long-term savings from reduced labor costs and material waste often tip the scales in favor of lasers.

Furthermore, traditional methods usually require more extensive post-processing work due to rough edges or inaccuracies in cuts. In contrast, a well-calibrated laser tube cutting machine delivers clean cuts right off the bat—saving you time and money on finishing processes down the line. So while traditional methods may appear cheaper at first glance, they often lack the efficiency that makes investing in advanced technology worthwhile.

Investment vs. Long-term Savings

When contemplating whether to invest in a laser tube cutting machine or stick with conventional methods, weighing short-term costs against long-term savings is essential for making an informed decision about your operations' future profitability. While upfront expenses for high-quality machines might make you gulp at first glance—especially if you're asking yourself how much does a tube laser cost?—the reality is that these machines often pay for themselves over time through enhanced productivity.

For instance, consider maintenance costs: you might wonder how long does a laser cutter tube last? With proper care—including routine checks and necessary upkeep—a well-maintained system can provide years of reliable service with minimal downtime compared to older technologies that frequently require repairs or replacement parts. Additionally, since modern machines tend to use less energy than their traditional counterparts while providing faster turnaround times on projects—they contribute significantly toward reducing overall operational expenses.

In summary: while investing in state-of-the-art machinery may feel daunting initially—the benefits it brings both financially (through savings) and operationally (through efficiency) are compelling reasons not only to consider but embrace this technology wholeheartedly!

How Thick Can a Tube Laser Cut?

Material Limitations and Capabilities

Every laser tube cutting machine has its limitations when it comes to material thickness, which largely depends on the type of laser used—CO2 or fiber lasers being the most common. Generally, CO2 lasers are better suited for cutting thicker materials, while fiber lasers excel at thinner applications with higher speed and accuracy. It's crucial to know these limitations; otherwise, you might end up asking yourself, How much does a tube laser cost? only to discover it can't handle your material's requirements.

Optimal Thickness for Efficient Cutting

For optimal efficiency, most laser tube cutting machines can effectively cut materials ranging from 1mm up to 25mm in thickness depending on their specifications and power output. The sweet spot for many applications tends to be around 10mm; this range allows for both speed and quality without compromising structural integrity. If you're wondering about What is the cost of laser cutting machine? keep in mind that machines capable of handling these optimal thicknesses often come with advanced features that justify their price tag.

Innovations Increasing Cutting Thickness

Recent innovations in laser technology have made it possible for newer machines to handle thicker materials than ever before—some even exceeding 30mm! These advancements include improved cooling systems, enhanced beam quality, and more powerful generators that allow for deeper penetration into tougher metals. As questions like “How long does a laser cutter tube last?” arise due to increased usage from these innovations, it's essential to consider regular maintenance as part of your investment strategy.

Maintenance and Longevity of Laser Cutters

When it comes to the longevity of a laser tube cutting machine, one of the most common questions is, How long does a laser cutter tube last? Typically, the lifespan of these machines can range from several years to over a decade, depending on usage and maintenance practices. A well-maintained laser cutter can significantly extend its operational life, ensuring that your investment continues to deliver value over time.

How Long Does a Laser Cutter Tube Last?

The lifespan of a laser cutter tube varies based on factors such as the quality of the machine and how frequently it is used. Generally speaking, many high-quality laser tubes can last anywhere from 1,000 to 10,000 operational hours before requiring replacement. Understanding How long does a laser cutter tube last? helps businesses plan for potential downtime and budget for future costs associated with maintaining their equipment.

Importance of Regular Maintenance

Regular maintenance is crucial for ensuring that your laser tube cutting machine operates at peak efficiency. Neglecting routine upkeep can lead to decreased performance and costly repairs down the line—nobody wants unexpected expenses when they could have been avoided! By establishing a regular maintenance schedule, you not only prolong the life of your equipment but also enhance productivity by minimizing disruptions in production.

Common Issues and Solutions

Despite their robust design, even the best laser tube cutting machines may experience issues over time. Common problems include misalignment, lens contamination, or even power fluctuations that affect cutting quality—questions like What is the cost of a laser cutting machine? often arise when these issues become apparent! Fortunately, many common problems have straightforward solutions: regular cleaning schedules can prevent lens contamination while proper alignment checks ensure consistent cuts.

Choosing the Right Laser Tube Cutter

Selecting the right laser tube cutting machine can feel like navigating a maze, but it doesn’t have to be daunting. With the right information, you can make an informed decision that aligns with your production needs and budget. This section will explore key features to consider, how to assess your production requirements, and how Kiant Machinery can assist in your selection process.

Key Features to Consider

When shopping for a laser tube cutting machine, several critical features should be on your radar. First and foremost is the cutting speed; faster machines can significantly boost productivity and reduce lead times. Additionally, consider the machine's versatility—can it handle various tube sizes and materials? Look for options that offer advanced automation capabilities to streamline operations further.

Another essential feature is precision; a high-quality laser tube cutter should provide clean cuts with minimal waste. The maximum thickness capability is also vital; understanding “how thick can a tube laser cut?” helps ensure you select a model that meets your material specifications. Lastly, don’t overlook software compatibility; intuitive controls can enhance usability and integration into existing workflows.

Understanding Your Production Needs

Before investing in a laser tube cutting machine, take time to evaluate your specific production needs thoroughly. Assess factors such as volume requirements—are you running large batches or smaller custom jobs? This will help determine whether you need a high-speed model or one that excels at intricate designs.

Also, consider the types of materials you'll be working with since different machines have varying capabilities regarding thickness and material types. If you're frequently asking yourself “how much does a tube laser cost?” remember that more specialized machines may come with higher price tags but could ultimately save money through efficiency gains over time.

Finally, think about future growth; choosing equipment that allows for scalability ensures you won't be left behind as demands increase or change.

Role of Kiant Machinery in Equipment Selection

Kiant Machinery plays an instrumental role in guiding businesses through the selection process of their ideal laser tube cutting machine. They offer expert insights into various models tailored to meet specific industry demands while considering factors like cost-effectiveness and long-term savings—after all, what is the cost of a laser cutting machine if it doesn’t deliver value?

Moreover, Kiant’s team understands common queries such as “how long does a laser cutter tube last?” providing customers with realistic expectations regarding maintenance and longevity of their investment. Their extensive product range ensures that every client finds something suitable without compromising on quality or performance.

In summary, collaborating with Kiant Machinery not only simplifies choosing the right equipment but also enhances overall operational efficiency through expert guidance tailored specifically for your needs.

Conclusion

In conclusion, the world of laser tube cutting machines is a dynamic one, constantly evolving to meet the demands of various industries. By leveraging the advantages of these advanced systems, manufacturers can significantly enhance their efficiency and precision in metal cutting operations. As technology continues to progress, the capabilities of laser tube cutting machines will only expand further, making them an indispensable tool in modern manufacturing.

Maximizing Efficiency with Laser Cutters

To maximize efficiency with a laser tube cutting machine, it’s essential to understand its operational strengths and how they align with production goals. The precision and speed offered by these machines can drastically reduce waste and increase output quality. Additionally, integrating automation into processes involving laser cutters can streamline workflows and minimize manual labor costs.

Comparing Costs of Laser Cutting Solutions

When pondering how much does a tube laser cost?, it’s crucial to consider not just the initial investment but also long-term savings associated with reduced material wastage and labor costs. While traditional cutting methods may seem cheaper upfront, they often incur higher operational expenses over time due to inefficiencies. By comparing these costs comprehensively, businesses can make informed decisions that favor long-term profitability.

The Future of Laser Technology in Manufacturing

The future of laser technology in manufacturing looks bright as innovations continue to emerge that expand capabilities—answering questions like how thick can a tube laser cut? or how long does a laser cutter tube last? With advancements in materials and engineering techniques, we are likely to see lasers capable of handling thicker materials while maintaining their precision over extended periods. This evolution positions laser tube cutting machines at the forefront of manufacturing technologies for years to come.