Introduction

In the world of modern manufacturing, tube laser cutting stands out as a revolutionary technology that has transformed the way metal components are fabricated. This advanced laser cutting process utilizes highly focused beams of light to precisely cut through various types of materials, including metals and plastics. By employing a laser cutter, manufacturers can achieve intricate designs and high-quality finishes with minimal waste, making it an essential tool in today's competitive landscape.

Understanding Tube Laser Cutting

Tube laser cutting refers specifically to the technique of using a laser machine to cut tubular materials with exceptional accuracy and speed. Unlike traditional methods that often involve mechanical saws or plasma cutters, tube laser cutting leverages the power of focused light to create clean, precise cuts in metal tubes and profiles. This method not only enhances productivity but also opens up new possibilities for complex geometries that were previously difficult or impossible to achieve.

Advantages of Laser Cutting Technology

The advantages of laser cutting technology are numerous and compelling for businesses looking to streamline their operations. First and foremost, a laser cutter provides unparalleled precision, ensuring that each machine cut metal piece adheres to exact specifications without the need for extensive post-processing. Additionally, this technology allows for faster production times compared to conventional methods, which translates into cost savings and increased output—an invaluable asset in any manufacturing environment.

Applications of Tube Laser Cutting

Tube laser cutting finds applications across various industries due to its versatility and efficiency. From automotive components to architectural elements, this technology is employed wherever intricate metal parts are required. Whether it's creating custom brackets or producing complex frames for machinery, the capabilities of a laser cutting machine make it an indispensable tool for engineers and designers alike.

What is Tube Laser Cutting

Tube laser cutting is a sophisticated method that utilizes laser technology to cut and shape metal tubes and pipes with precision. Unlike traditional cutting methods, which may rely on blades or saws, this innovative approach harnesses the power of focused laser beams to achieve clean cuts and intricate designs. This technique has revolutionized the way industries handle metal fabrication, making it an essential component in modern manufacturing processes.

Defining Laser Cutting Techniques

Laser cutting techniques encompass a variety of methods that use concentrated light to slice through materials with remarkable accuracy. At its core, tube laser cutting employs high-powered lasers that can be finely tuned to cut through different types of metals, including steel, aluminum, and brass. This versatility allows for intricate designs and complex shapes that would be challenging or impossible to achieve with conventional machine cut metal approaches.

How Tube Laser Cutting Works

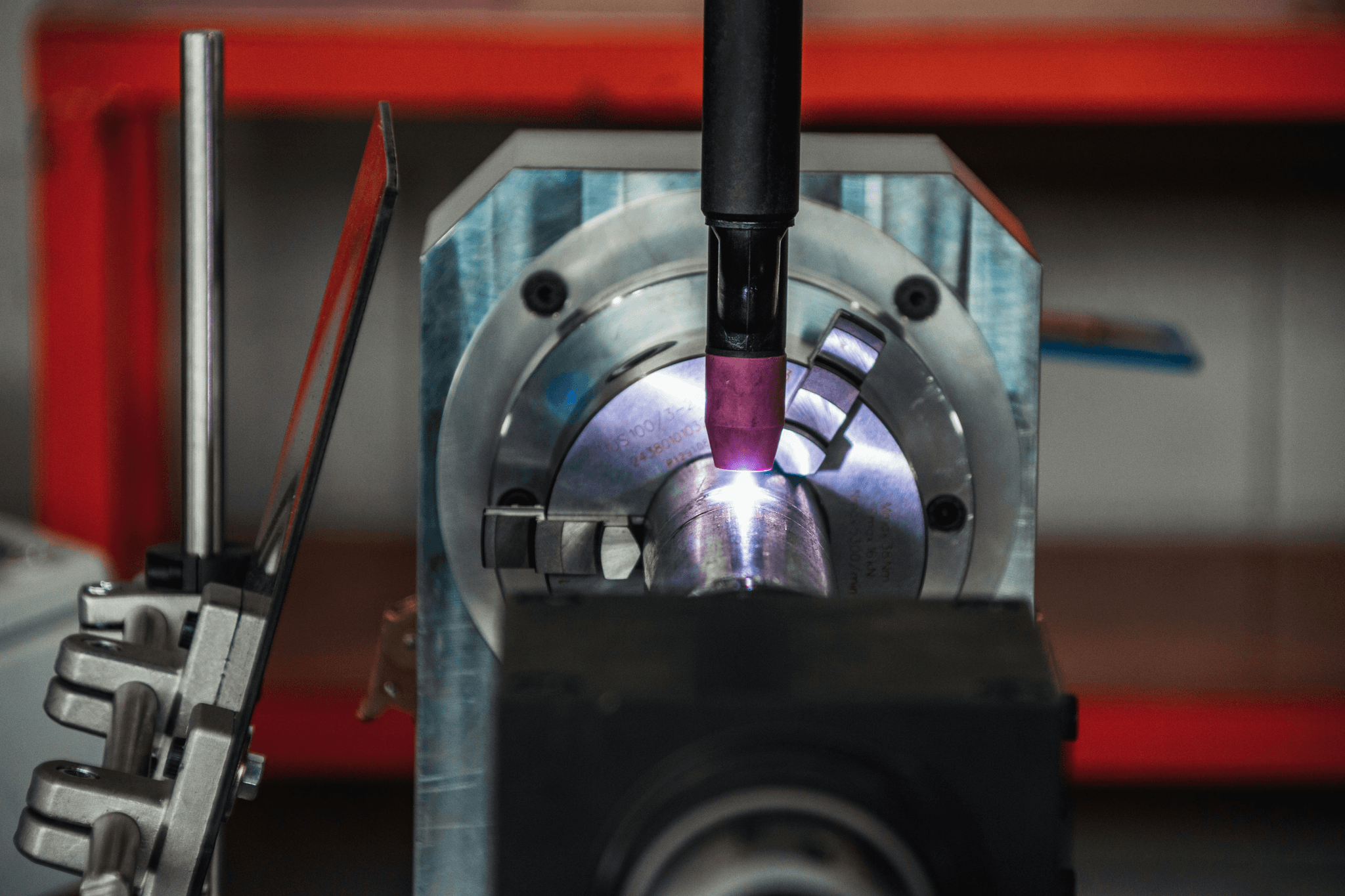

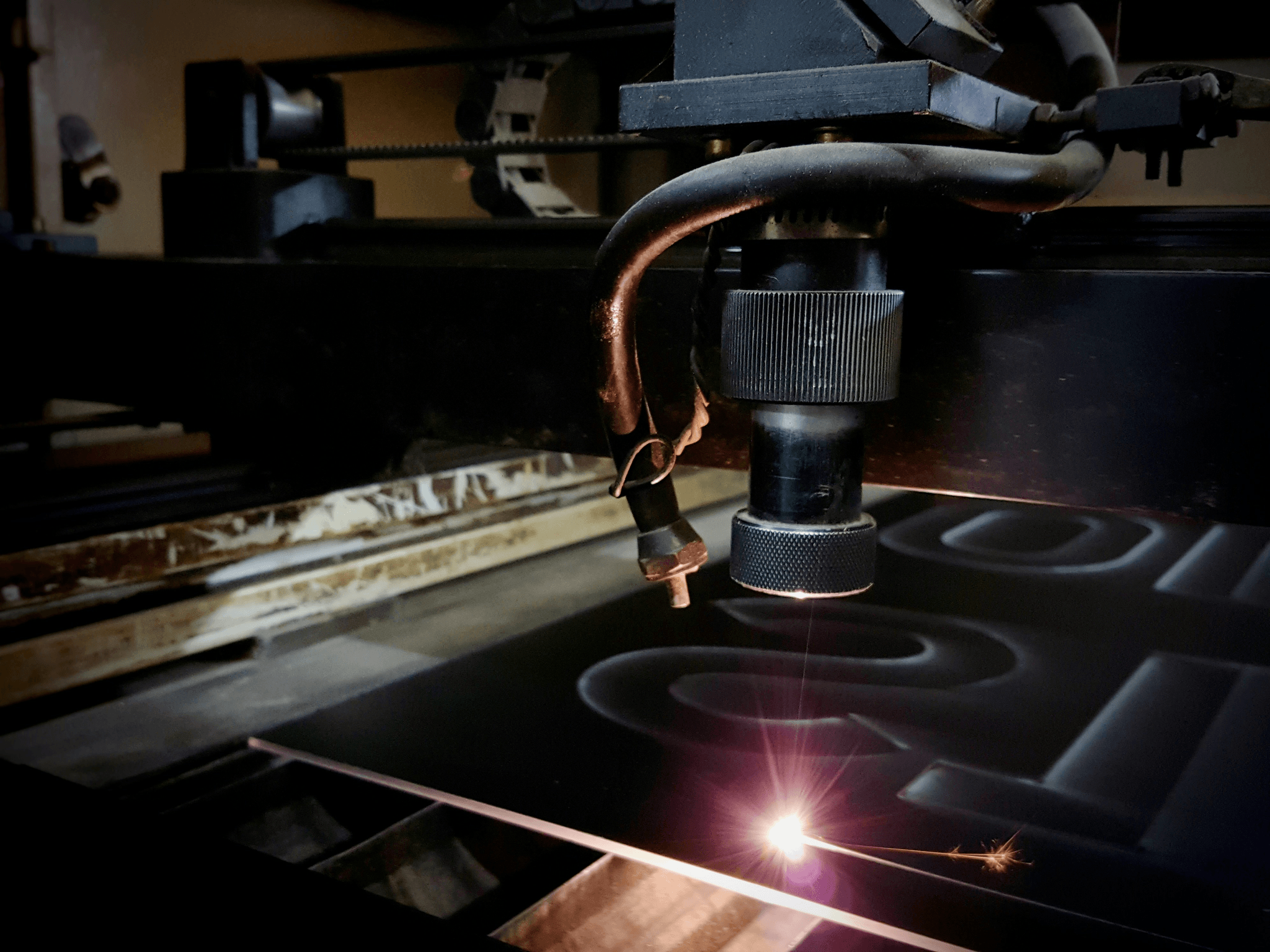

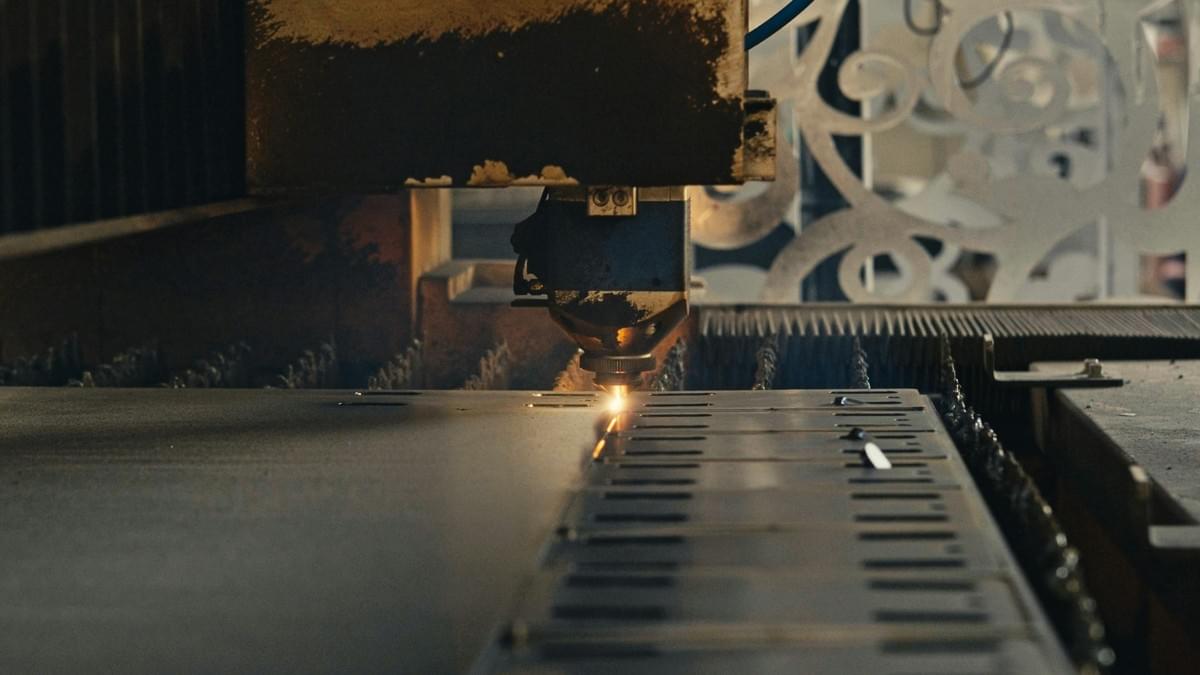

In tube laser cutting, a laser cutter directs a focused beam onto the material's surface while simultaneously moving along predetermined paths. The intense heat generated by the laser melts or vaporizes the metal at the point of contact, creating a precise cut without causing significant deformation or waste. This process is not only efficient but also ensures high-quality results, making it a preferred choice for industries requiring detailed work.

Common Types of Tube Laser Cutters

There are several common types of tube laser cutters available in today’s market, each designed to meet specific cutting needs and material types. Fiber lasers are particularly popular due to their efficiency and ability to cut through thicker materials with ease; they excel in delivering high-quality cuts quickly. On the other hand, CO2 lasers are known for their versatility and can handle various materials but may require more maintenance compared to fiber options—both have their place in the realm of metal cutting machine lasers.

Key Advantages of Tube Laser Cutting

When it comes to tube laser cutting, the benefits are hard to ignore. This innovative technology has revolutionized the way we approach metal fabrication, offering unparalleled advantages over traditional methods. From precision cuts to speedier production times, tube laser cutting stands out as a game-changer in the industry.

Precision and Accuracy of Cuts

Precision is the name of the game in any metalworking endeavor, and tube laser cutting delivers on this front with flying colors. A laser cutter can achieve intricate designs and tight tolerances that would be nearly impossible with conventional machining methods. The ability to cut complex shapes with such accuracy not only enhances product quality but also minimizes waste material during the metal cutting process.

The advanced technology behind a laser machine allows for adjustments in real-time, ensuring that every cut is exact and consistent across batches. This level of detail is particularly advantageous for industries where specifications are critical, such as aerospace or automotive manufacturing. Ultimately, when you're looking to machine cut metal with finesse, tube laser cutting is your go-to solution for precision.

Speed and Efficiency in Production

In today’s fast-paced manufacturing environment, speed matters more than ever—and that's where tube laser cutting really shines. Compared to traditional methods, a laser cutting machine can significantly reduce processing times while maintaining high-quality output. With rapid setup times and continuous operation capabilities, these machines can handle large volumes of work without breaking a sweat.

Moreover, the efficiency gained through automation means that operators can focus on other tasks while the machine takes care of intricate cuts at lightning speed. This not only boosts productivity but also allows businesses to meet tight deadlines without compromising on quality or precision. When you need quick turnaround times for your projects, investing in a metal cutting machine laser becomes an obvious choice.

Cost-Effectiveness Compared to Traditional Methods

Cost savings are always welcome in any business operation; thankfully, tube laser cutting offers significant financial advantages too! While initial investment costs may seem higher for a state-of-the-art laser cutter compared to older machinery, the long-term benefits quickly outweigh those expenses. Reduced labor costs due to automation combined with less material waste means that companies can see substantial savings over time.

Additionally, because these machines require less downtime for maintenance and offer faster production rates, businesses experience improved cash flow by getting products out the door quicker than ever before. The overall efficiency translates into lower operational costs per unit produced—making it an attractive option for manufacturers looking to maximize their profits while delivering high-quality products consistently. When comparing cost-effectiveness between various methods of machining metals, it's clear that a laser machine stands head-and-shoulders above its competitors.

Choosing the Right Laser Cutting Machine

Selecting the right laser cutting machine is a crucial step in optimizing your tube laser cutting operations. With various options available, it's essential to consider factors such as material compatibility, cutting speed, and overall functionality. A well-chosen laser cutter can significantly enhance your production capabilities and streamline your metal cutting processes.

Factors to Consider When Selecting

When it comes to choosing a laser cutting machine, several factors play a pivotal role in ensuring you make the right investment. First, assess the types of materials you'll be working with; different machines may excel at cutting various metals or thicknesses. Next, consider the power of the laser; higher wattage generally translates into faster and more efficient cuts on thicker materials.

Additionally, think about automation features that can enhance productivity—some machines come equipped with advanced software that optimizes cut paths for maximum efficiency. Don't forget to factor in maintenance requirements as well; some models demand more upkeep than others, which could affect your long-term operational costs. Ultimately, aligning these elements with your business needs will lead you to the ideal metal cutting machine laser for your operations.

Popular Brands in the Market

The market boasts several reputable brands known for their high-quality tube laser cutting machines. Names like Trumpf and Bystronic are often at the forefront due to their innovative technology and reliable performance in various applications. Meanwhile, companies like Amada and Mitsubishi also offer impressive options tailored for specific industries.

Each brand has its unique strengths; for instance, Trumpf is celebrated for its user-friendly interfaces while Bystronic focuses on high-speed precision cuts. Researching customer reviews and industry feedback can provide insights into which brand aligns best with your specific needs in tube laser cutting technology. Investing time into understanding these brands will ensure you select a machine that not only meets but exceeds your expectations.

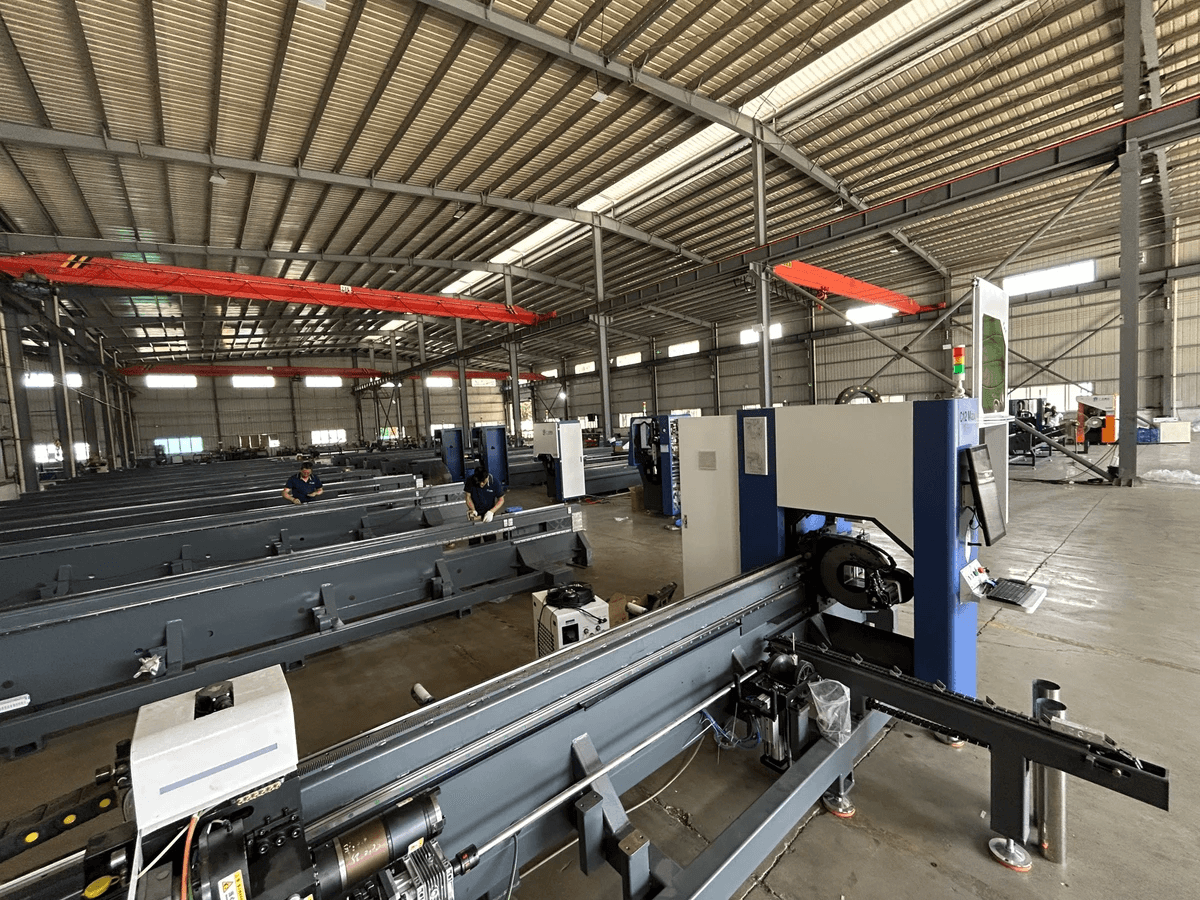

Kiant Machinery's Offerings and Expertise

Kiant Machinery stands out as a formidable player in the world of tube laser cutting solutions by combining quality engineering with exceptional customer service. Their range of products includes state-of-the-art laser machines designed specifically for efficient metal processing across diverse industries. Kiant Machinery’s expertise lies not just in providing equipment but also offering tailored solutions that address each client's unique challenges.

What sets Kiant apart is their commitment to innovation; they continually update their offerings based on emerging technologies and market demands—ensuring customers have access to advanced features that boost productivity and accuracy in metal cutting tasks. Additionally, their knowledgeable team offers unparalleled support from selection through installation and beyond—making sure you get the most out of your new laser cutter investment. With Kiant Machinery by your side, elevating your operations through effective tube laser cutting becomes an achievable goal.

Tube Laser Cutting Techniques Explained

Tube laser cutting has revolutionized the way we approach metal fabrication, offering a variety of techniques to cater to different needs. Understanding these approaches is essential for businesses looking to maximize efficiency and precision in their operations. From simple cuts to complex designs, the right technique can make all the difference when it comes to tube laser cutting.

Different Approaches to Tube Cutting

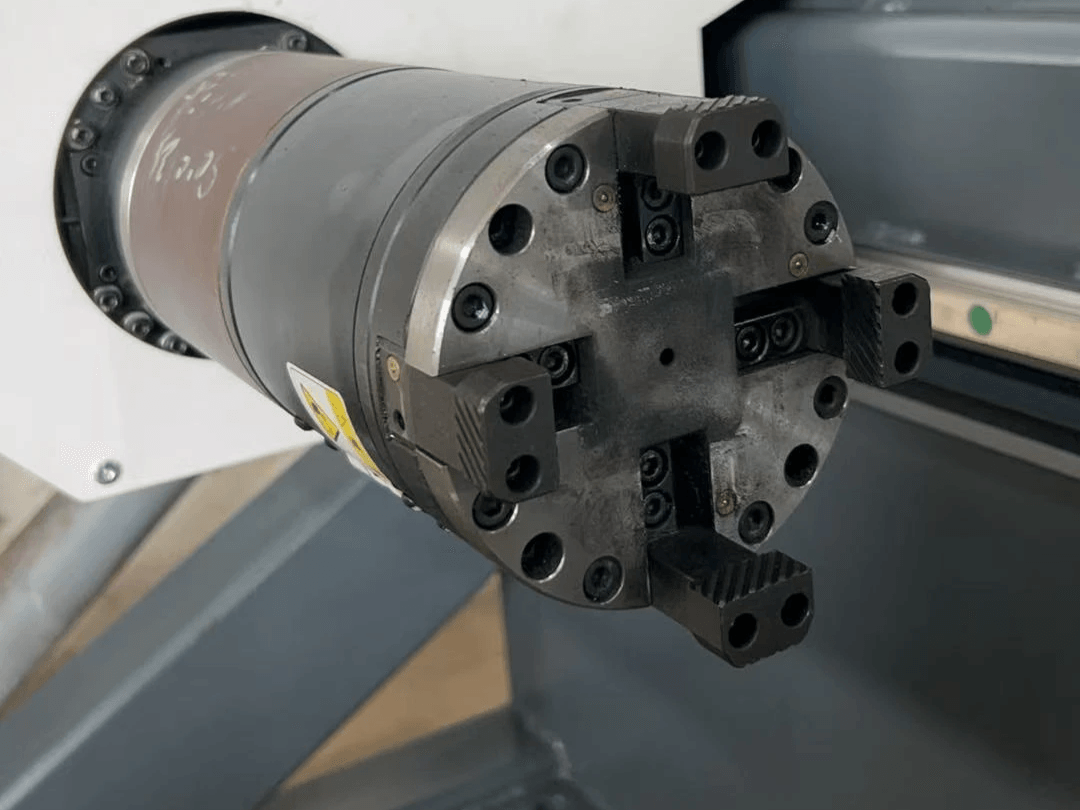

There are several methods employed in tube laser cutting, each tailored for specific applications and materials. Common techniques include 2D and 3D cutting, where 2D focuses on flat surfaces while 3D allows for intricate shapes in three-dimensional space. Additionally, some machines integrate rotary axes that enable continuous rotation of the tube during the cutting process, enhancing versatility and precision.

Another popular approach is using a combination of traditional machining with laser technology, which can significantly streamline production processes. This hybrid method allows for initial rough cuts with a metal cutting machine laser before finishing with a high-precision laser cutter for detailed work. By leveraging multiple techniques, manufacturers can achieve higher quality results while reducing waste and production time.

Comparing Fiber vs. CO2 Laser Technology

When discussing tube laser cutting technologies, fiber and CO2 lasers often come up as two leading options on the market today. Fiber lasers utilize solid-state technology that produces light through optical fibers, making them highly efficient and capable of delivering exceptional beam quality for metal cutting applications. In contrast, CO2 lasers use gas mixtures to generate their beams; they are traditionally favored for thicker materials but may require more maintenance than fiber systems.

One significant advantage of fiber lasers in tube laser cutting is their ability to cut reflective metals such as aluminum and copper effectively—something CO2 lasers struggle with due to their longer wavelengths. Moreover, fiber lasers tend to have lower operational costs because they consume less energy and require minimal cooling compared to CO2 systems. As industries continue evolving towards faster production times with high-quality outputs, fiber technology is becoming increasingly popular among those investing in new laser cutting machines.

Innovations in Tube Laser Cutting

The landscape of tube laser cutting is continuously evolving thanks to innovative advancements in technology that enhance performance and capabilities. One noteworthy trend is the integration of automation into metal cutting machine lasers; this includes features like automatic loading/unloading systems that streamline workflow while minimizing human error during operation. Such innovations not only improve productivity but also allow operators more time to focus on complex design tasks rather than repetitive manual labor.

Another exciting development involves software enhancements that enable advanced nesting algorithms—maximizing material usage by optimizing cut layouts before processing begins on a laser machine or cutter system. These smart technologies help reduce scrap material significantly while ensuring precise cuts every time you engage your machine cut metal projects! As manufacturers strive for sustainability alongside efficiency gains, these innovations represent a promising future direction within the sector.

Maintenance and Best Practices

Maintaining your tube laser cutting machine is crucial for ensuring optimal performance and longevity. A well-cared-for laser cutter not only enhances productivity but also minimizes downtime, which can be costly for any operation. By following best practices in maintenance, you can keep your metal cutting machine laser running smoothly for years to come.

Ensuring Longevity of Your Laser Cutter

To ensure the longevity of your laser cutter, start by adhering to a strict cleaning schedule. Regularly removing dust and debris from the machine’s components will prevent buildup that could affect performance during metal cutting operations. Additionally, keeping the optics clean is vital; dirty lenses can lead to poor beam quality, resulting in inaccurate cuts and wasted materials.

Another critical factor in extending the life of your tube laser cutting equipment is monitoring its operating conditions. Ensure that the environment around your laser machine is conducive to its operation—this includes maintaining appropriate temperature and humidity levels. Finally, consider investing in quality parts and components; using subpar replacements can lead to premature wear and tear on your laser cutting machine.

Routine Maintenance Tips

Routine maintenance should include several key tasks that keep your tube laser cutting system functioning at peak efficiency. Start with regular inspections of all mechanical parts, including belts, gears, and bearings; replacing worn components before they fail can save you from unexpected breakdowns. Additionally, lubricating moving parts according to manufacturer guidelines will help reduce friction and prolong the life of these components.

Don’t overlook software updates either! Keeping your firmware updated ensures that you benefit from enhancements in performance and security features designed specifically for laser cutting operations. Lastly, maintain a logbook documenting all maintenance activities—this practice not only helps track when services are due but also provides valuable insights into potential recurring issues with your metal cutting machine laser.

Troubleshooting Common Issues

Even with diligent maintenance practices in place, issues may still arise with your tube laser cutter from time to time. One common problem is inconsistent cut quality; if you notice variations in thickness or finish quality, it may be time to check alignment or recalibrate settings on the cutting laser metal equipment. In many cases, troubleshooting involves simple adjustments like tightening loose screws or realigning mirrors.

Another frequent issue is overheating during prolonged use; if this occurs, inspect cooling systems such as fans or water chillers for proper function. Overheating can lead not only to reduced efficiency but also permanent damage if left unchecked! Lastly, don’t hesitate to consult user manuals or contact support when faced with more complex problems—sometimes a second opinion can save you hours of frustration.

Conclusion

In the ever-evolving landscape of manufacturing, tube laser cutting stands out as a game-changer, revolutionizing how we approach metal fabrication. As we look to the future, advancements in technology promise even greater precision and efficiency, making this method an essential tool for industries worldwide. Embracing these innovations will not only enhance production capabilities but also redefine quality standards in metal cutting.

Future Trends in Tube Laser Cutting

The future of tube laser cutting is bright, with trends leaning towards increased automation and integration with AI technologies. This evolution will enable a laser cutter to optimize processes in real-time, reducing waste and improving accuracy during the metal cutting process. Additionally, the rise of eco-friendly practices may lead to more energy-efficient laser cutting machines that minimize environmental impact while maximizing output.

Maximizing Efficiency with Laser Machines

To truly harness the power of a laser machine, manufacturers must focus on optimizing their operations through smart scheduling and workflow management. By investing in high-quality equipment like advanced laser cutting machines, businesses can significantly reduce downtime and increase production speed without sacrificing precision.

How Kiant Machinery Can Enhance Your Operations

Kiant Machinery stands at the forefront of innovation in tube laser cutting technology, offering state-of-the-art solutions tailored to your specific needs. With a diverse range of metal cutting machine lasers designed for various applications, Kiant ensures you have access to top-tier equipment that enhances productivity and quality. By partnering with Kiant Machinery, you gain not only superior products but also expert support that can elevate your operations to new heights.