Introduction

In the realm of modern manufacturing, laser machine cutting has emerged as a game-changer, revolutionizing how materials are processed and shaped. This advanced technology utilizes focused laser beams to cut through various materials with precision and speed, making it an essential tool for industries ranging from automotive to creative arts. As we dive deeper into the world of laser cutting, we will explore its cost implications, advantages, and applications across diverse sectors.

Understanding Laser Machine Cutting

So, what is machine laser cutting? At its core, it's a process that employs high-powered lasers to slice through materials like metal, wood, plastic, and more with incredible accuracy. The technology behind this process involves converting electrical energy into light energy via a laser source and then focusing that light onto the material surface to achieve cuts that traditional methods simply cannot match.

Key Advantages of Laser Cutting

One of the primary reasons industries opt for laser machine cutting is its unparalleled precision. Cuts are clean and intricate without requiring extensive finishing work afterward; this saves both time and resources. Additionally, the versatility of different types of lasers—such as CO2 laser machines—allows users to tackle a wide range of materials effectively while maintaining low operational costs.

Applications Across Industries

Laser cutting isn't just confined to one sector; it finds applications in manufacturing and fabrication as well as in creative arts for prototyping designs. From crafting intricate components in aerospace to producing custom signage in small businesses, the adaptability of this technology is remarkable. Understanding where these machines can be applied opens up numerous opportunities for innovation across various fields while answering questions like What is the best laser cutter for home use? or How much does a laser cutter cost to operate?

What is Laser Machine Cutting?

Laser machine cutting is a modern fabrication technique that utilizes focused laser beams to cut through various materials with precision. This technology has revolutionized manufacturing processes, enabling intricate designs and high-quality finishes that were once difficult to achieve. Understanding the fundamentals of what machine laser cutting entails is essential for anyone considering its applications in their business or home projects.

Definition and Technology

At its core, laser machine cutting refers to the process of using a high-powered laser beam to slice through materials such as metal, wood, plastic, and fabric. The technology behind this process involves directing a concentrated light beam onto the material’s surface, which heats it up until it melts or vaporizes. This method not only allows for clean cuts but also minimizes waste and reduces the need for secondary finishing processes.

How Laser Cutting Works

So, how does this fascinating process actually work? When you engage a laser cutting machine, it emits a focused beam of light that moves across the material in a predetermined pattern based on computer-aided design (CAD) files. The intense heat generated by the laser effectively melts or burns away the material along the path of the beam while an assist gas—like oxygen or nitrogen—helps blow away molten debris, resulting in smooth edges and precise cuts.

Common Types of Laser Cutting Machines

There are several types of laser cutting machines available on the market today, each tailored for specific applications and materials. The most common types include CO2 laser machines and fiber lasers; both have their unique advantages depending on your needs. For instance, CO2 lasers are typically preferred for non-metal materials like wood and acrylic due to their efficiency with these substrates, while fiber lasers excel at cutting metals due to their shorter wavelength.

The Cost of Laser Cutting Machines

When considering laser machine cutting, one of the first questions that comes to mind is, What is the cost of laser cutting machines? The price can vary significantly based on the type and capabilities of the machine. Generally, entry-level models start around $2,000, while high-end industrial machines can exceed $100,000.

What is the Cost of Laser Cutting Machine?

The cost of a laser cutting machine depends on several factors including its size, power output, and features. For instance, a basic CO2 laser machine designed for hobbyists may range from $2,000 to $10,000. In contrast, a robust fiber laser cutter suitable for industrial applications can range from $20,000 to upwards of $100,000.

When asking “What is machine laser cutting?” it’s important to note that these costs also reflect the technology’s precision and versatility. The initial investment might seem daunting but consider it as an investment in efficiency and quality that pays off over time through reduced waste and improved production speed.

Factors Influencing Laser Cutting Costs

Several factors influence the overall costs associated with laser cutting machines beyond just their purchase price. One major factor includes maintenance expenses; high-quality machines may require less frequent servicing than cheaper alternatives. Additionally, operating costs such as electricity consumption and consumables like lenses or gases play a crucial role in determining how much does a laser cutter cost to operate?

Another aspect to consider is whether you need specialized features like automation or larger working areas; these enhancements can significantly increase your initial investment but also enhance productivity. Lastly, brand reputation and warranty offerings can affect pricing—established brands often charge more due to their reliability and support services.

Comparing Prices: CO2 Laser Machine vs. Fiber Laser

When comparing prices between CO2 laser machines and fiber lasers, it's essential to recognize their unique strengths and weaknesses in terms of cost-effectiveness. Typically, CO2 lasers are less expensive upfront than fiber lasers but may incur higher operational costs due to gas requirements for operation and maintenance needs over time.

On the other hand, while fiber lasers tend to have a higher initial price tag—often starting around $25,000—they offer lower operating costs due to energy efficiency and reduced consumable expenses over their lifespan. This comparison illustrates that while CO2 lasers may be appealing for budget-conscious users looking for “What is the best laser cutter for home use?”, fiber lasers shine in long-term savings particularly suited for industrial applications.

Choosing the Right Laser Cutter

When it comes to selecting a laser cutter, the options can be overwhelming. Whether you’re a hobbyist or a small business owner, understanding your needs is crucial to finding the right machine for you. This section will guide you through what to consider when making your choice, from home use options to budget-friendly recommendations.

What is the Best Laser Cutter for Home Use?

If you're wondering, What is the best laser cutter for home use? you're not alone! Many enthusiasts seek a compact yet powerful machine that fits their workspace without sacrificing performance. Ideal choices often include CO2 laser machines due to their versatility and ability to cut or engrave various materials like wood, acrylic, and leather—perfect for crafting and DIY projects.

Home users should also consider entry-level fiber lasers if they primarily work with metals; however, these may require a larger investment. It's essential to assess your specific needs—do you plan on creating intricate designs or simply cutting shapes? This will help narrow down your options significantly.

Essential Features to Look For

When shopping for a laser cutting machine, several features can enhance your experience and productivity. First off, consider the power of the laser; higher wattage typically means faster cutting speeds and thicker material capabilities. Additionally, look for user-friendly software that allows easy design uploads—this can save you time in the long run.

Another important feature is bed size; larger beds accommodate bigger projects but also take up more space in your workshop or garage. Finally, don’t overlook safety features such as enclosures or automatic shut-off systems—these are crucial when operating any type of laser machine cutting equipment at home.

Recommendations for Different Budgets

Laser cutters come in various price ranges, so knowing what fits your budget is essential when asking yourself: What is the cost of laser cutting machine? For those on a tight budget (under $500), desktop CO2 lasers can provide excellent value while still delivering quality results for small projects.

Mid-range options ($500-$2000) often include machines with better build quality and additional features like larger working areas and enhanced software compatibility. If you're willing to invest more than $2000, high-end fiber lasers offer unparalleled precision and speed—ideal for small businesses looking to expand their capabilities.

In summary, whether you’re exploring entry-level models or professional-grade machines, there’s an option out there that suits both your needs and budget perfectly!

Operating Costs of a Laser Cutter

Operating a laser cutter is more than just the initial investment; it’s about understanding the ongoing costs that come with this high-tech equipment. When considering what is machine laser cutting, one must factor in operational expenses such as energy consumption, maintenance, and consumables. Knowing how much does a laser cutter cost to operate can help businesses and hobbyists make informed decisions.

How Much Does a Laser Cutter Cost to Operate?

The operating costs of a laser cutter can vary widely based on several factors, including the type of machine and its usage frequency. For instance, CO2 laser machines tend to have different operating expenses compared to fiber lasers; generally, fiber lasers are more energy-efficient but may come with higher upfront costs. On average, users might expect monthly operational costs ranging from $200 to $1,000 depending on their specific needs and how much they utilize their laser machine cutting capabilities.

Understanding what is the cost of laser cutting machine operation also involves looking at material types being processed. Different materials require varying levels of power and time to cut or engrave effectively—this means that your choice of materials can significantly influence overall operational expenses.

Maintenance and Consumables

Maintenance plays a crucial role in ensuring that your laser cutting machine operates efficiently over time. Regular upkeep may include cleaning lenses, replacing filters, and checking alignment—all tasks that can add up if not managed properly. Consumables like gas for CO2 lasers or fiber optics for fiber lasers also contribute to ongoing costs; these items need periodic replacement based on usage levels.

Additionally, knowing what is the best laser cutter for home use often leads users to overlook maintenance needs until issues arise. By investing in quality components upfront and adhering to a solid maintenance schedule, operators can minimize unexpected breakdowns and costly repairs—keeping their operations smooth and efficient.

Energy Efficiency Considerations

Energy efficiency is another critical factor when evaluating the operating costs associated with laser cutting machines. The type of technology used—whether it's CO2 or fiber—can have significant implications on energy consumption during operation. Fiber lasers typically consume less power than CO2 lasers while providing faster cutting speeds; thus they are often favored for high-volume production environments.

Moreover, understanding how much does a laser cutter cost to operate extends beyond mere electricity bills; it incorporates overall efficiency metrics such as speed versus power consumption ratios during operation. By optimizing settings according to specific projects or materials being cut, users can maximize output while minimizing energy waste—a win-win scenario for both productivity and cost-effectiveness in any application involving laser machine cutting.

Applications and Industries Utilizing Laser Cutting

Laser machine cutting has become a transformative technology across various sectors, revolutionizing how products are manufactured and designed. Its precision, speed, and versatility make it an ideal choice for industries ranging from manufacturing to creative arts. Let’s dive into some of the primary applications where laser cutting shines.

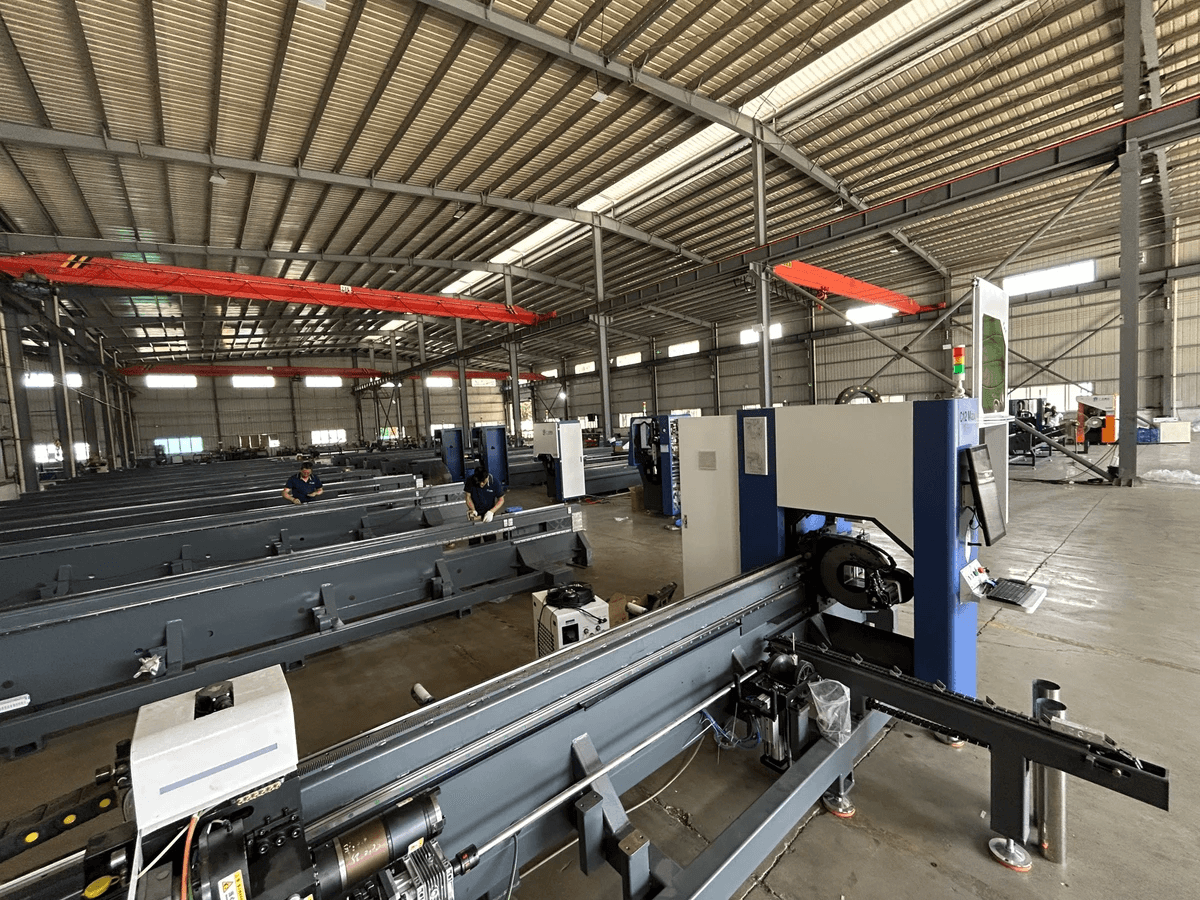

Manufacturing and Fabrication

In the realm of manufacturing and fabrication, laser machine cutting is a game-changer. It allows for intricate designs to be cut with unparalleled accuracy, which is essential when working with materials like metal, plastic, or wood. Many manufacturers are now asking themselves: What is machine laser cutting? The answer lies in its ability to produce high-quality components while minimizing waste—a crucial factor for maintaining profitability.

Moreover, the efficiency of laser cutting machines reduces production times significantly compared to traditional methods. This means businesses can meet tight deadlines without compromising on quality or precision. As manufacturers increasingly look toward automation and advanced technologies, understanding What is the cost of a laser cutting machine? becomes vital for budgeting and investment strategies.

Automotive and Aerospace Industries

The automotive and aerospace industries have embraced laser cutting technology due to its exceptional capability in handling complex shapes needed for parts like brackets, panels, and structural components. With stringent safety standards in these sectors, the accuracy provided by CO2 laser machines ensures that every component meets regulatory requirements without fail. The question often arises: How much does a laser cutter cost to operate? In these industries, operational costs are balanced against the high precision that can lead to fewer defects.

Additionally, the lightweight materials used in modern vehicles benefit greatly from laser cutting techniques that minimize heat-affected zones—critical for maintaining material integrity during fabrication processes. As companies strive for innovation while reducing costs, leveraging advanced technologies like fiber lasers has become increasingly common in both automotive and aerospace applications.

Creative Arts and Prototyping

In the world of creative arts and prototyping, laser machine cutting opens up endless possibilities for artists and designers alike. Whether it's crafting intricate jewelry designs or producing detailed prototypes for product development, this technology allows creators to bring their visions to life with stunning detail. Many hobbyists ponder: What is the best laser cutter for home use? Fortunately, there are several options available that cater specifically to smaller-scale projects without sacrificing performance.

Moreover, artists appreciate how quickly they can iterate designs using a laser cutter—making it easier than ever to experiment with new ideas without extensive material waste or time delays. This ease of use makes it accessible even for those who may not have extensive technical backgrounds but wish to explore their creative potential through precision crafting tools.

Conclusion

In the ever-evolving world of manufacturing and design, laser machine cutting has emerged as a game changer. With its precision, speed, and versatility, it’s clear that this technology will continue to shape various industries for years to come. As we look ahead, the future of laser cutting is likely to see advancements in efficiency and affordability, making it accessible for even more applications.

The Future of Laser Machine Cutting

The future of laser machine cutting is bright and brimming with possibilities. Innovations in technology are paving the way for more efficient machines that not only cut faster but also reduce operational costs significantly—addressing the common question: What is the cost of laser cutting machine? As new materials are developed and integrated into production processes, we can expect laser cutting techniques to adapt accordingly, enhancing their capabilities across different sectors.

Choosing Kiant Machinery for Your Needs

When it comes to selecting a laser cutter that fits your requirements, Kiant Machinery stands out as a reliable option. Whether you’re asking yourself What is the best laser cutter for home use? or seeking industrial-grade solutions, their range offers something for everyone. With competitive pricing and exceptional support services tailored to your needs, Kiant Machinery ensures that you have everything necessary to succeed in your projects involving laser machine cutting.

Final Thoughts on Laser Cutting Efficiency

In conclusion, understanding how much does a laser cutter cost to operate is crucial when considering this investment for your business or creative endeavors. The efficiency gained from using a CO2 laser machine or other types can lead to significant savings over time—both financially and in terms of resource consumption. Embracing this technology not only enhances productivity but also positions businesses at the forefront of innovation in their respective fields.