Introduction

In the ever-evolving world of manufacturing, the laser cutting system has emerged as a game-changer, revolutionizing the way we approach metal fabrication. With unparalleled precision and speed, laser cutters have become indispensable tools for various industries. Understanding these sophisticated machines is crucial for anyone looking to enhance their production capabilities.

Understanding Laser Cutting Systems

Laser cutting systems utilize focused beams of light to slice through materials with remarkable accuracy. This technology enables metal cutting laser cutters to achieve intricate designs that traditional methods often struggle with. By harnessing the power of lasers, cutting machine lasers can deliver clean edges and reduced kerf width, making them ideal for high-quality metalwork.

Importance of Choosing the Right Laser Cutter

Selecting the right laser cutter can significantly impact your operational efficiency and product quality. With numerous options available in the market, understanding your specific needs is essential to make an informed decision. A well-chosen metal cutting machine laser can enhance productivity while minimizing waste and downtime.

Overview of Laser Machinery Types

The landscape of laser machinery is diverse, encompassing various types suited for different applications and materials. From CO2 lasers best for non-metal materials to fiber lasers designed specifically for cutting metals, each type has its unique advantages and limitations. Familiarizing yourself with these options will empower you to select a system that aligns perfectly with your business requirements.

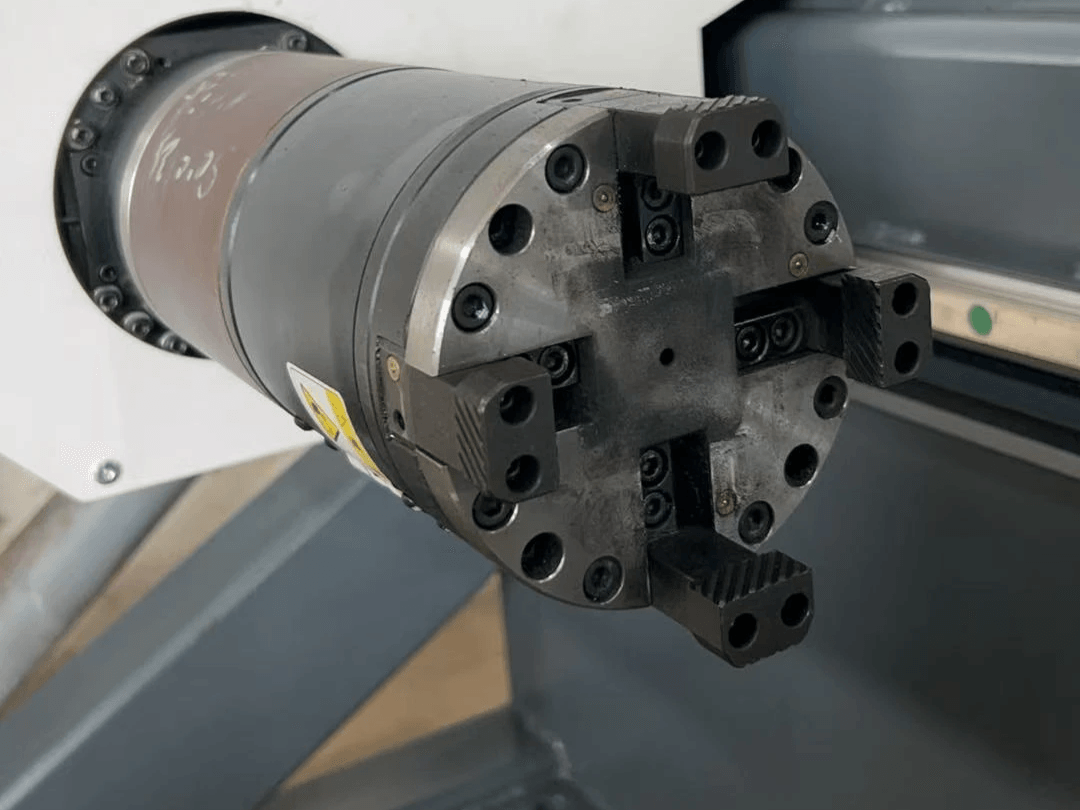

How Laser Cutters Work

Laser cutters are fascinating machines that utilize advanced technology to slice through materials with precision and efficiency. Understanding the inner workings of a laser cutting system is crucial for anyone looking to invest in a metal cutting laser cutter or cutting machine laser. This section will delve into the science behind laser cutting, explore key components of these systems, and highlight the various types of lasers used in metal cutting.

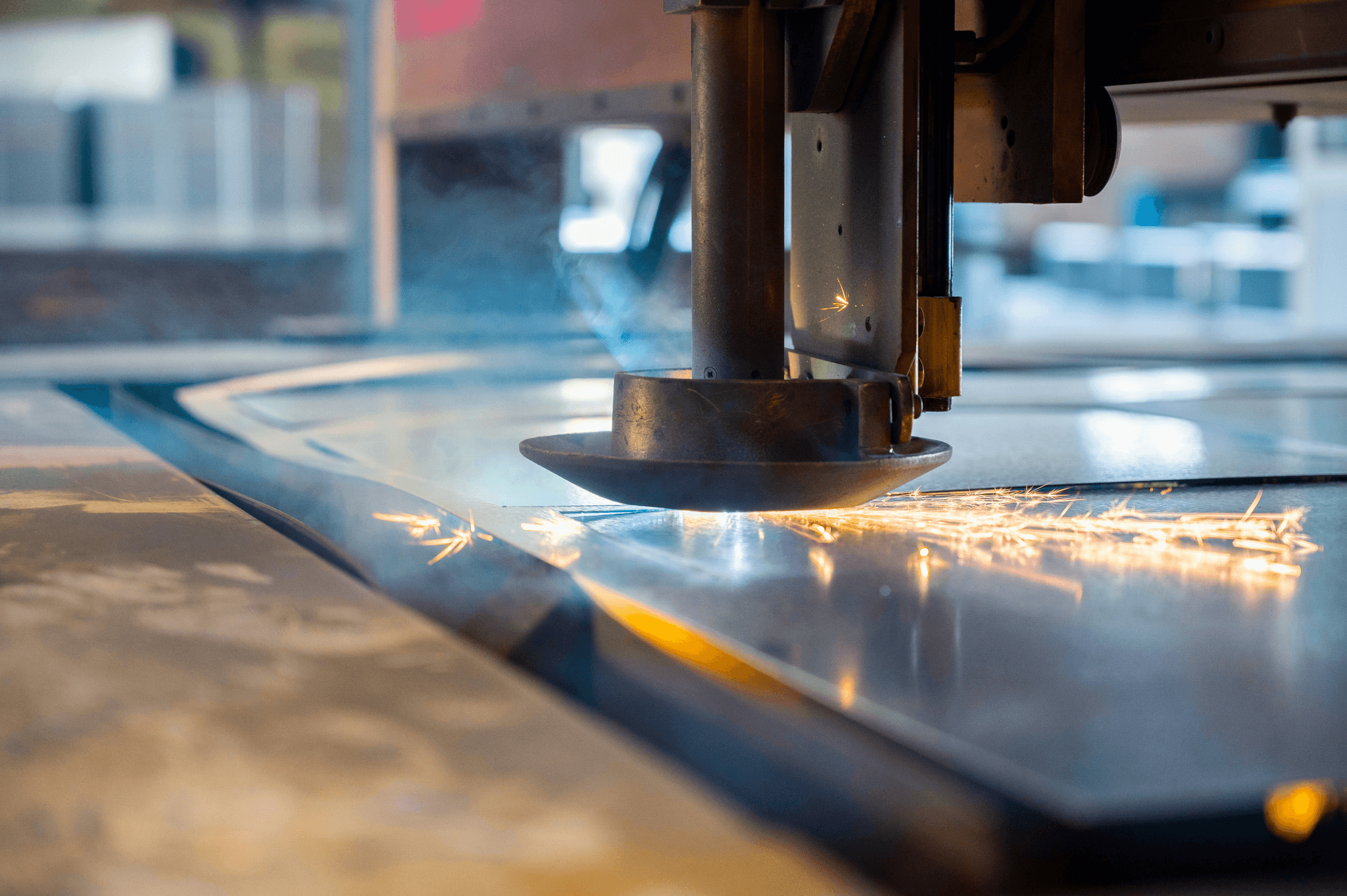

The Science Behind Laser Cutting

At its core, laser cutting is a process that uses focused light energy to melt, burn, or vaporize material away from a workpiece. The intense beam generated by a laser cutter can reach temperatures high enough to cut through thick metals with ease, making it an essential tool in manufacturing and fabrication industries. This method not only ensures clean cuts but also minimizes heat-affected zones, which can compromise material integrity.

The precision of the laser beam allows for intricate designs and complex patterns that would be challenging with traditional machining methods. By controlling the speed and movement of the laser head, operators can achieve varying depths and widths of cuts without compromising accuracy. This level of control makes metal cutting machines lasers indispensable for applications requiring high-quality finishes.

Types of Lasers Used in Metal Cutting

The most common types include CO2 lasers and fiber lasers; each type has its own strengths depending on factors like power output and material compatibility. CO2 lasers are well-suited for thicker materials due to their ability to produce higher wattage beams.

On the other hand, fiber lasers excel at delivering fast processing speeds while maintaining exceptional cut quality on thin metals like aluminum or stainless steel—making them popular choices among manufacturers seeking efficiency without sacrificing precision in their projects. Understanding these distinctions helps users select an appropriate metal cutting machine laser based on their specific requirements.

Selecting the Best Laser Cutter for Your Needs

Choosing the right laser cutting system can feel like finding a needle in a haystack, especially with so many options available. Whether you're a small workshop or a large manufacturing facility, understanding your specific needs is crucial for making an informed decision. This section will guide you through essential factors to consider, how to compare metal cutting laser cutters effectively, and budgeting tips to ensure you get the best bang for your buck.

Factors to Consider When Choosing a Laser Cutter

When selecting a laser cutter, it's vital to assess what materials you'll be working with and the thickness of those materials. Different metal cutting machines have varying capabilities; some excel at thin sheets while others are designed for thicker stock. Additionally, consider the speed and precision required for your projects—some cutting machine lasers offer faster speeds but might sacrifice accuracy.

Another critical factor is the size of the work area that your metal cutting laser cutter will need. If space is limited in your workshop or factory, opting for a compact model could save you from future headaches. Lastly, think about whether you'll need additional features like automation or software integration; these can enhance productivity but may also increase costs.

Comparing Metal Cutting Laser Cutters

With numerous models on the market, comparing metal cutting laser cutters can seem daunting at first glance. Start by looking at specifications such as wattage and beam quality—higher wattage typically means faster cutting speeds but also comes with higher energy consumption. Don't forget to read user reviews and testimonials; real-world experiences often highlight strengths and weaknesses that specs alone cannot convey.

Another point of comparison should be maintenance requirements; some laser machinery demands more upkeep than others, which can impact your long-term operational costs. It's also wise to evaluate customer support services offered by manufacturers since having reliable assistance can save you time and trouble down the road if issues arise with your laser cutting system. Ultimately, create a comparison chart that includes all these factors to help visualize which machine meets your needs best.

Budgeting for Your Laser Cutting System

Budgeting is where dreams meet reality in acquiring a new laser cutter! Start by determining how much you're willing to invest upfront while keeping in mind that cheaper isn't always better when it comes to quality machinery like this—consider it an investment rather than just another piece of equipment. Factor in ongoing costs such as maintenance, consumables (like lenses), and potential upgrades when calculating total ownership expenses.

Don't overlook financing options if budget constraints are tight; many manufacturers provide flexible payment plans that allow businesses of all sizes access to advanced technology without breaking the bank immediately. Additionally, keep an eye out for grants or subsidies aimed at promoting technological innovation within industries that could offset some costs associated with purchasing new equipment like metal cutting machines or systems.

The Advantages of Laser Cutting Technology

Laser cutting technology has transformed the landscape of manufacturing, offering numerous advantages that make it a preferred choice for many industries. From precision to versatility, the benefits of using a laser cutting system are compelling for anyone involved in metal fabrication. Understanding these advantages can help businesses make informed decisions when investing in laser machinery.

Precision and Accuracy in Metal Cutting

One of the standout features of a metal cutting laser cutter is its ability to deliver exceptional precision and accuracy. The focused beam of light allows for intricate designs and tight tolerances that traditional cutting methods often struggle to achieve. This level of detail not only enhances the quality of finished products but also reduces the need for post-processing adjustments, saving time and money.

Moreover, with advancements in laser technology, modern cutting machine lasers can maintain consistent performance across various materials and thicknesses. This reliability means that manufacturers can trust their laser cutting system to produce identical parts every time—ideal for large-scale production runs where uniformity is critical. In essence, a metal cutting machine laser elevates production standards by ensuring each cut is flawless.

Versatility of Cutting Machine Lasers

Another significant advantage of laser cutters lies in their versatility; they can handle an array of materials beyond just metals, including plastics, wood, and composites. This adaptability makes them an invaluable asset for businesses looking to diversify their product offerings without investing in multiple machines. Whether you're crafting delicate designs or robust components, a well-equipped laser cutting system can rise to any challenge.

Additionally, different types of lasers—such as CO2 and fiber lasers—expand the capabilities even further by allowing users to select the best option based on their specific needs. For instance, while CO2 lasers excel at non-metal materials like acrylics or wood, fiber lasers shine when it comes to high-speed metal processing. Consequently, this versatility ensures that a single cutting machine laser can serve multiple purposes across various projects.

Reduced Waste and Enhanced Efficiency

Efficiency is paramount in manufacturing today; thus, one cannot overlook how a metal cutting laser cutter minimizes waste during production processes. The precision cuts generated by these machines mean less material is wasted compared to traditional methods that may require additional trimming or finishing work later on. This not only conserves resources but also translates into cost savings over time—a win-win situation!

Moreover, with faster processing speeds inherent in modern laser machinery systems, businesses can produce more parts within shorter timeframes without sacrificing quality or precision. This increased throughput enables manufacturers to meet tight deadlines while maintaining high standards—a crucial factor in today’s competitive market landscape. Ultimately, reduced waste combined with enhanced efficiency makes investing in a reliable laser cutter an intelligent choice for any forward-thinking operation.

Maintenance and Care for Your Laser Cutting System

Maintaining your laser cutting system is crucial for ensuring optimal performance and longevity. Regular upkeep not only enhances the efficiency of your metal cutting laser cutter but also minimizes downtime, which can be costly in a production environment. By following a structured maintenance routine, you can keep your cutting machine laser in top shape and avoid potential issues down the line.

Routine Maintenance Tips for Laser Machinery

Routine maintenance for your laser machinery should include regular inspections of critical components such as lenses, mirrors, and the cooling system. Clean these parts frequently to prevent debris from affecting the quality of cuts produced by your metal cutting machine laser. Additionally, check the alignment of the laser beam and ensure that all moving parts are lubricated to maintain smooth operation.

Another essential aspect of routine maintenance is monitoring the power settings and calibration of your laser cutter. Keeping track of these parameters helps avoid inconsistent cuts that could compromise material integrity or lead to waste. Lastly, don’t overlook software updates; keeping your control software current ensures that you benefit from improvements in functionality and safety features.

Troubleshooting Common Issues

Even with diligent care, issues may arise with your laser cutting system from time to time. One common problem is misalignment, which can result in uneven cuts or excessive wear on components; this often requires recalibrating the machine or adjusting settings on your metal cutting laser cutter. If you encounter inconsistent power output, it may indicate a dirty lens or mirror—cleaning these elements usually resolves such problems quickly.

Another frequent issue involves overheating during prolonged operation; ensuring proper ventilation and monitoring coolant levels can help mitigate this risk significantly. If you notice strange noises or vibrations while operating the cutting machine laser, it might signal mechanical wear that needs addressing before it escalates into more significant damage. Keeping a log of any recurring problems will also assist when seeking solutions or professional support.

When to Seek Professional Support

While many maintenance tasks can be handled in-house, there are times when it's best to call in professionals for assistance with your laser cutting system. If you encounter complex issues like electrical malfunctions or persistent misalignment after performing routine checks, it's wise to consult experts who specialize in repairing metal cutting machines lasers. They possess both the experience and tools necessary to diagnose problems accurately without risking further damage.

Additionally, if you're unsure about performing specific maintenance tasks yourself—such as replacing delicate components—it’s better to err on the side of caution by seeking professional help instead of attempting DIY fixes that could void warranties or lead to costly repairs later on. Regularly scheduled professional inspections can also extend the lifespan of your equipment by identifying potential issues before they escalate into significant failures.

Innovations in Laser Cutting Systems

The world of laser cutting systems is constantly evolving, propelled by technological advancements that enhance efficiency and precision. Innovations in laser technology not only improve the capabilities of laser cutters but also expand their applications across various industries. As we dive into these advancements, it’s clear that the future of metal cutting laser cutters holds exciting prospects for manufacturers and users alike.

Advancements in Laser Technology

Recent developments in laser technology have revolutionized how we perceive metal cutting machines. High-powered fiber lasers, for instance, offer faster cutting speeds and greater energy efficiency compared to traditional CO2 lasers. These advancements allow for a more versatile range of materials to be processed, from thin sheets to thicker plates, making the cutting machine laser an indispensable tool in modern manufacturing.

Moreover, automation and integration with software solutions are enhancing the functionality of these machines. Smart technologies enable real-time monitoring and adjustments during operation, significantly reducing downtime and increasing productivity. As a result, businesses utilizing advanced laser machinery can achieve higher output while maintaining exceptional quality standards.

The Future of Cutting Machines in Manufacturing

The future landscape of manufacturing is poised to be heavily influenced by innovations in laser cutting systems. With the rise of Industry 4.0, integrating IoT (Internet of Things) capabilities into metal cutting machines allows for smarter operations and data-driven decision-making processes. This shift not only maximizes efficiency but also minimizes waste—a crucial factor as industries strive for sustainability.

Additionally, trends such as additive manufacturing are beginning to intersect with traditional subtractive methods like those employed by metal cutting laser cutters. This convergence could lead to hybrid machines that combine both technologies for enhanced versatility and creativity in product design and fabrication processes. As we look ahead, it’s evident that the evolution of cutting machine lasers will redefine manufacturing paradigms.

Kiant Machinery's Role in Industry Innovations

Kiant Machinery stands at the forefront of these innovations within the realm of laser cutting systems. By consistently investing in research and development, they ensure their products remain competitive while meeting evolving customer needs across various sectors—be it automotive, aerospace or general fabrication industries. Their commitment to quality means that users can rely on Kiant's metal cutting machines not just for performance but also for longevity.

Furthermore, Kiant Machinery actively collaborates with tech partners to incorporate state-of-the-art features into their machinery offerings—think automated loading systems or advanced software integration options that optimize workflow management effectively! These strategic initiatives position them as leaders within an industry ripe with potential for growth and transformation through innovative practices.

Conclusion

In wrapping up our exploration of laser cutting systems, it's evident that these machines are more than just tools; they are transformative technologies that redefine precision in metal fabrication. Understanding the intricacies of how a laser cutter operates and the various types available can significantly influence your manufacturing processes. Whether you're a hobbyist or a professional, investing in the right metal cutting laser cutter can elevate your projects to new heights.

Key Takeaways on Laser Cutting Systems

Laser cutting systems offer unparalleled precision and versatility, making them indispensable in modern manufacturing. The choice of a metal cutting machine laser is crucial, as it directly impacts the quality and efficiency of your work. Remember to consider factors like power output, material compatibility, and operational costs when selecting a cutting machine laser for your needs.

Investing in Quality Laser Machinery

Investing in quality laser machinery is not merely about initial purchase costs; it's about long-term value and performance. High-quality laser cutters tend to have better durability and require less frequent maintenance, ultimately saving you money over time. By choosing a reputable brand known for its innovations in metal cutting laser cutters, you ensure that your investment pays off through enhanced productivity and reduced downtime.

Resources for Laser Cutter Owners

For those who own or are considering purchasing a laser cutting system, numerous resources can help you maximize its potential. Online forums, manufacturer websites, and instructional videos offer valuable insights into best practices for operating and maintaining your equipment effectively. Additionally, connecting with other users can provide tips on troubleshooting common issues with your metal cutting machine laser.