Introduction

In the world of manufacturing and design, laser cutting has emerged as a game-changer, offering precision and versatility that traditional methods simply can't match. Understanding the intricacies of laser cutting price is essential for businesses looking to invest in this technology. With various options available, from entry-level machines to industrial giants, knowing how much does laser cutting cost? can help you make an informed decision.

Understanding Laser Cutting Basics

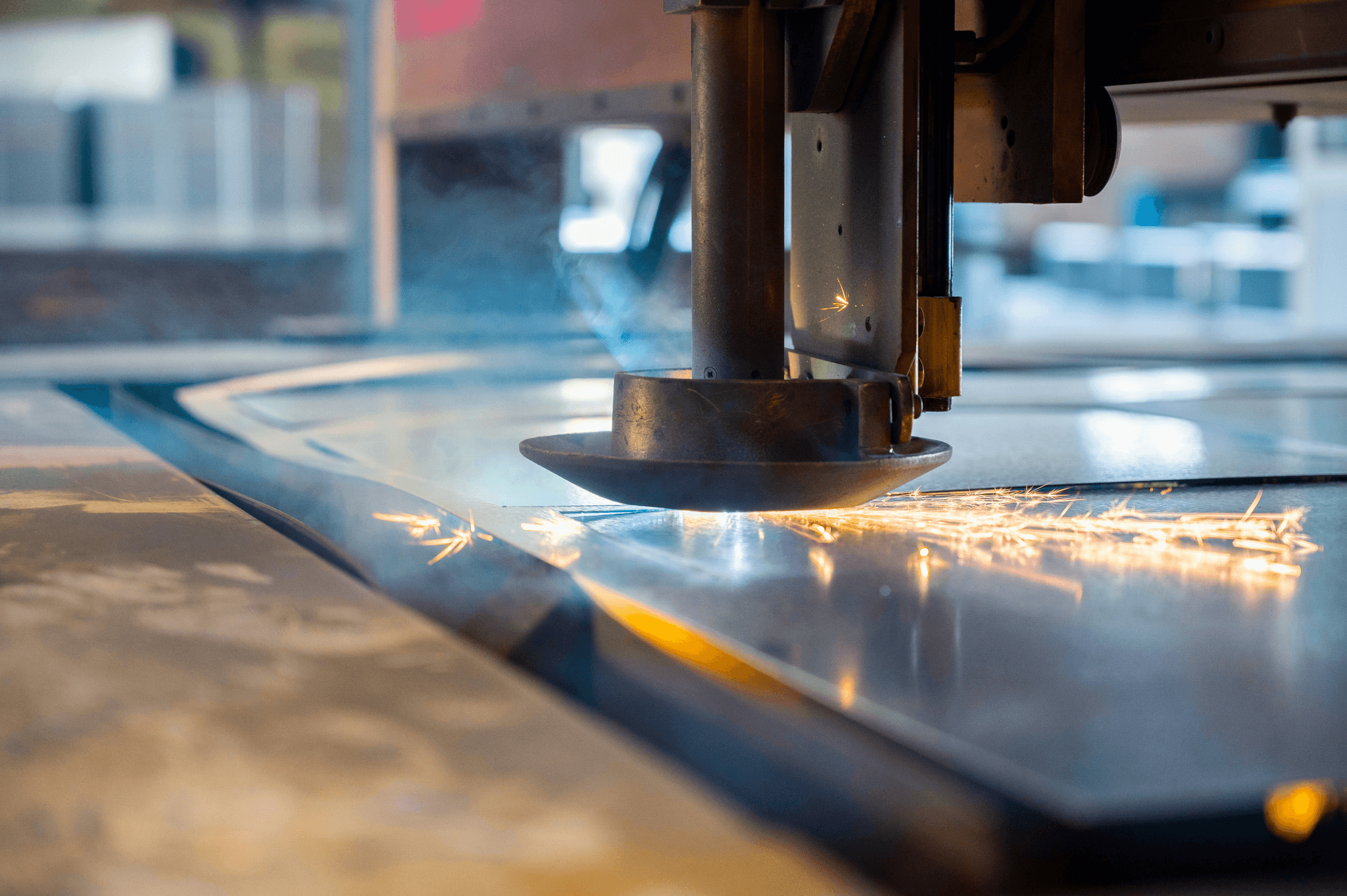

Laser cutting is a process that uses focused beams of light to slice through materials with incredible accuracy. This method is favored for its ability to work with a variety of materials, including metals, plastics, and wood, making it a popular choice across different industries. However, mastering the basics also means understanding what drives the laser cutting machine price up or down.

Factors Influencing Laser Cutting Machine Price

Several factors come into play when determining the price of a laser cutting machine. The type of material being cut and its thickness can significantly affect costs; thicker or harder materials typically require more powerful machines and higher operational expenses. Additionally, features such as speed, precision capabilities, and brand reputation all contribute to why is laser cutting so expensive?

Overview of Laser Cutting Options

When considering your options for laser cutting machines in 2025 Best Laser Cutting Machines reviews often highlight three main types: CO2 lasers, fiber lasers, and hybrid models that combine both technologies. Each type has its unique advantages that cater to specific applications and budgets; thus understanding these differences can help you choose wisely based on your needs. Ultimately, evaluating your choices will lead you closer to finding the right balance between quality and cost in your investment.

What Affects Laser Cutting Price

Material Type and Thickness

One of the most significant factors affecting laser cutting price is the type and thickness of the material being processed. Different materials, such as metals, plastics, or wood, require varying levels of power and precision from your laser cutting machine. For instance, thicker materials generally demand more powerful machines and longer processing times, which can significantly increase how much does laser cutting cost?

Additionally, specialized materials may require unique settings or even different types of lasers altogether—further complicating your investment in a machine suited for specific tasks. In 2025, best laser cutting machines will likely include advanced features to handle a wider range of materials efficiently. Therefore, knowing what you plan to cut can save you both time and money in the long run.

Machine Specifications and Features

When evaluating laser cutting machine price, it's essential to consider specifications such as wattage, speed capabilities, and additional features like automated loading systems or advanced software integration. Higher wattage typically translates into faster cuts and the ability to handle thicker materials; however, this also raises costs significantly. If you're asking yourself why is laser cutting so expensive?, remember that enhanced capabilities often come with a premium price tag.

Moreover, modern machines often come equipped with features designed to improve efficiency and accuracy—think autofocus systems or real-time monitoring—which can add more dollars to your initial investment but might save you operational costs over time. As technology evolves towards 2025 best laser cutting machines will likely offer even more sophisticated options that could change how you view value versus cost in this industry.

Labor and Operating Costs

Labor costs are another critical factor influencing overall laser cutting price that often gets overlooked during budgeting discussions. Skilled operators are necessary for running high-end machines effectively; thus their wages contribute significantly to your total expenditure on projects involving laser cutting services or machinery ownership. Additionally, operating costs such as electricity consumption—especially for higher-powered systems—can stack up quickly depending on usage frequency.

You also need to factor in maintenance expenses associated with keeping your equipment running smoothly over time; regular upkeep ensures optimal performance while minimizing downtime due to repairs or malfunctions linked back to neglecting service schedules. Ultimately understanding these labor-related aspects helps clarify how much does laser cutting cost beyond just purchasing an initial setup.

Types of Laser Cutting Machines

CO2 Laser Cutting Machines

CO2 laser cutting machines are among the most popular options in various industries due to their versatility and effectiveness in cutting non-metal materials like wood, acrylic, and certain plastics. They utilize a gas mixture that produces a high-quality beam capable of delivering intricate cuts with smooth edges, which is essential for detailed designs. However, while CO2 machines may have a lower initial purchase price compared to other types, their operational costs can add up over time due to maintenance and gas refills.

In terms of laser cutting machine price, CO2 lasers typically range from entry-level models suitable for hobbyists to more advanced versions designed for industrial use. The flexibility of these machines often leads users to question why some options are more expensive than others—usually due to factors like power output and additional features such as automated settings or software compatibility. Overall, if you're looking at 2025 Best Laser Cutting Machines lists, you'll likely find several CO2 options that balance performance with affordability.

Fiber Laser Cutting Machines

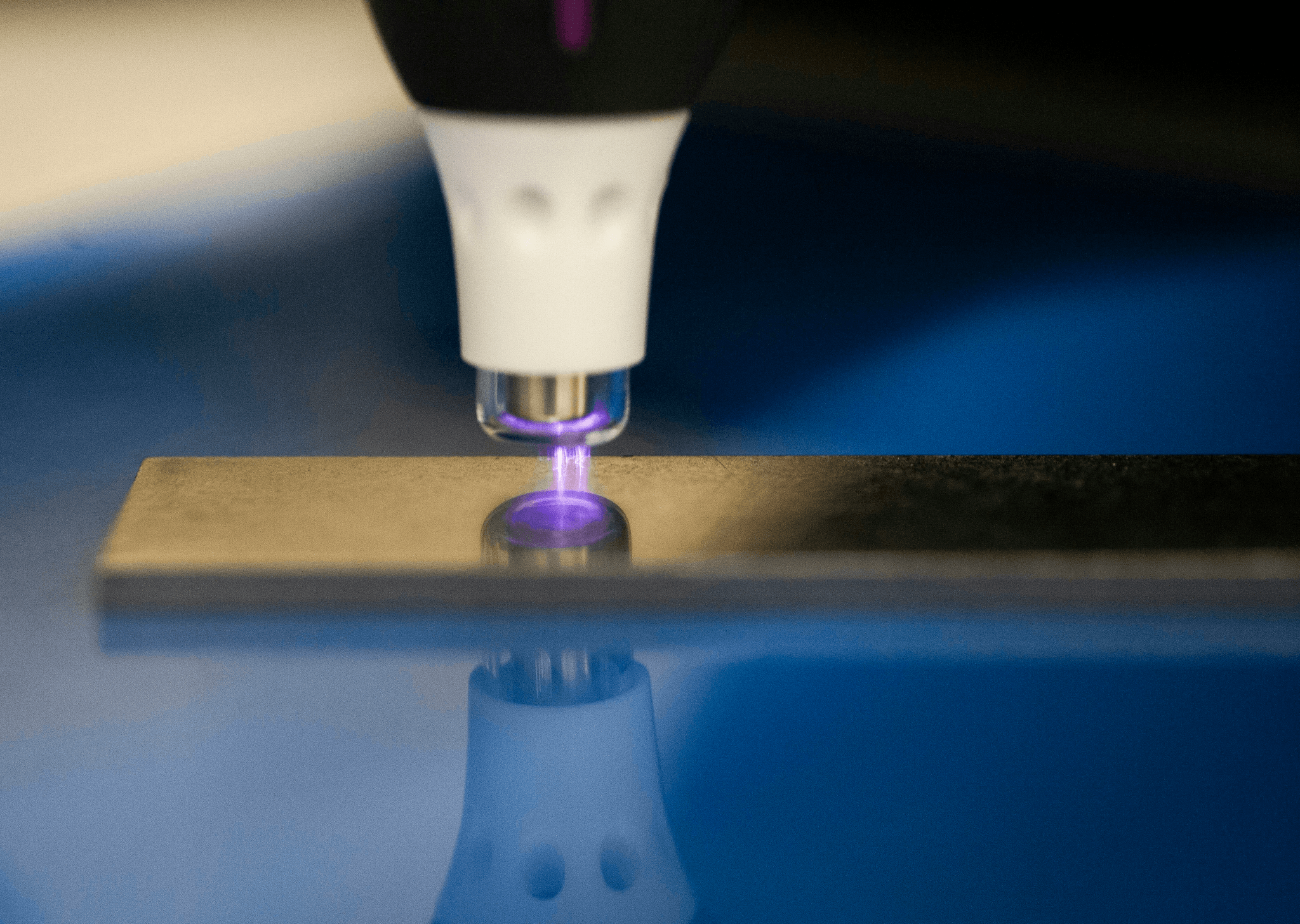

On the other hand, fiber laser cutting machines have gained immense popularity in recent years due to their efficiency in processing metals like steel and aluminum. These machines utilize solid-state lasers that offer faster speeds and higher energy efficiency compared to traditional CO2 lasers. As a result, while the initial investment might be higher—often leading potential buyers to ask how much does laser cutting cost?—the long-term savings on operational costs can make them an attractive option.

Fiber lasers excel at providing precise cuts with minimal heat-affected zones (HAZ), which is critical when working with delicate metal components or when precision is paramount. Consequently, the laser cutting machine price tends to reflect this advanced technology; many businesses justify the expense by considering reduced labor costs and less material waste over time. If you're exploring your options among 2025 Best Laser Cutting Machines, fiber lasers will likely stand out for their speed and accuracy.

Hybrid Laser Cutting Machines

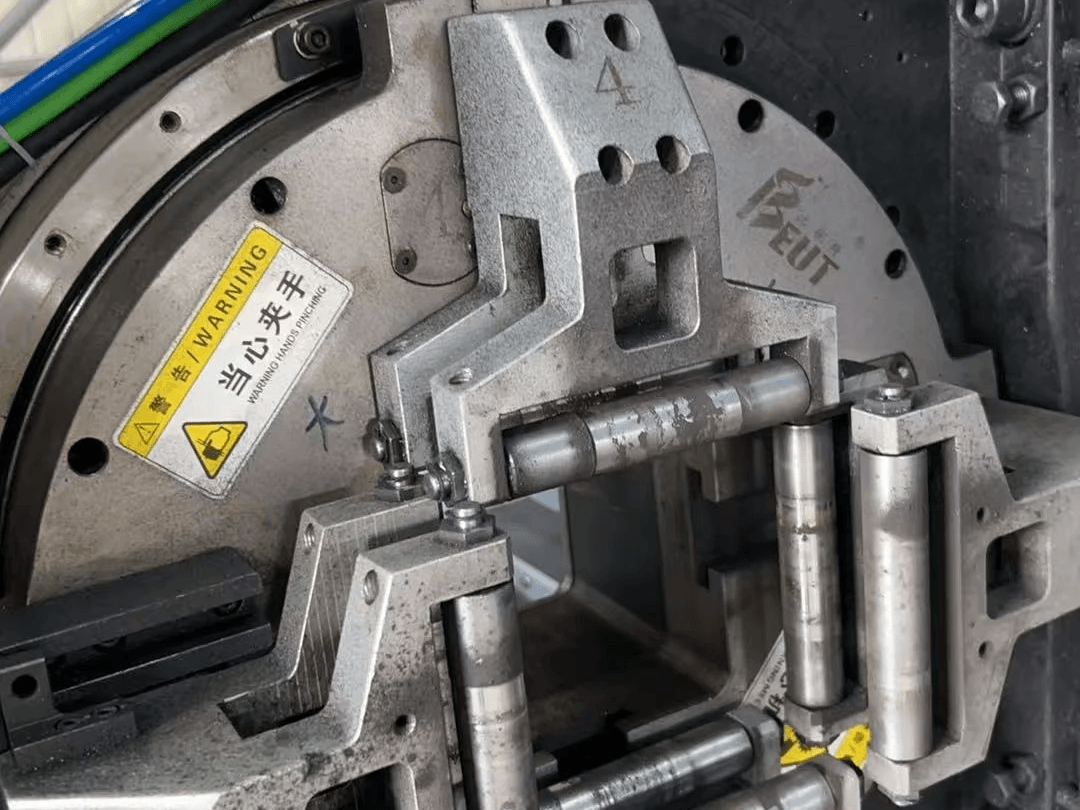

Hybrid laser cutting machines combine the best features of both CO2 and fiber technologies into one versatile unit—offering flexibility across various materials including both metals and non-metals alike. This adaptability makes them an appealing choice for manufacturers who work with diverse projects but want to keep their equipment streamlined without sacrificing quality or performance levels. However, this versatility also means that hybrid models often come at a premium price point.

When evaluating hybrid systems in terms of laser cutting price versus functionality, it's crucial to consider your specific needs as well as potential future projects that might require varied material types or thicknesses. Many buyers often wonder why is laser cutting so expensive? In part because hybrid systems incorporate sophisticated technology designed for high productivity rates while maintaining precision across different substrates—a feature not all single-type systems can boast about effectively! If you're searching through lists like 2025 Best Laser Cutting Machines or comparing brands online, don't overlook hybrids; they could be worth every penny spent.

Comparing Laser Cutting Machine Price

Entry-Level vs. Industrial Machines

Entry-level laser cutting machines are typically designed for small businesses or hobbyists looking to explore the world of laser cutting without breaking the bank. These machines generally have lower power outputs and fewer features, making them more affordable but also less versatile when it comes to material handling and thicknesses. On the other hand, industrial machines come equipped with advanced technology and higher wattage, allowing for precision cutting on a wider range of materials—naturally leading to a higher laser cutting machine price.

When asking How much does laser cutting cost?, it's essential to consider your specific needs as an entry-level machine may range from $5,000 to $20,000 while industrial models can soar up to $200,000 or more depending on their specifications. The investment in an industrial machine often pays off in efficiency and production capabilities over time; however, if you're just starting out or have limited projects in mind, an entry-level model might be your best bet without sacrificing too much quality. Ultimately, weighing these options will help you find a balance between initial costs and long-term returns.

Popular Brands and Their Prices

The market is saturated with various brands offering different types of laser cutting machines at varying prices—making it crucial to know which ones stand out in terms of quality and value for money. Some popular brands include Epilog Laser, Trotec Laser, and Universal Laser Systems; each offers unique features that cater to different user needs while also affecting their respective laser cutting prices significantly. For instance, you might find that Epilog's entry-level models start around $7,500 while their high-end systems can reach upwards of $50,000.

If you're eyeing fiber lasers specifically for metalwork applications due to their efficiency in energy usage and speed—brands like Trumpf or Bystronic are industry leaders but come at a premium price tag often exceeding $100,000 for advanced configurations. When considering the 2025 Best Laser Cutting Machines list that highlights both performance metrics and customer satisfaction ratings alongside pricing structures will ensure you make an informed choice tailored specifically towards your business goals.

Cost-Benefit Analysis

Conducting a cost-benefit analysis is vital when determining whether investing in a particular laser cutting machine is worthwhile given its associated costs versus expected returns over time. While it's tempting to focus solely on the upfront laser cutting machine price tag—consider how much you'll save on labor costs due to improved efficiency or enhanced product quality from using state-of-the-art technology like hybrid lasers compared with traditional methods!

Moreover—don’t forget potential maintenance expenses down the line; why is laser cutting so expensive? Advanced machinery requires regular upkeep which can add up quickly if not factored into your overall budget plan! Thus weighing these costs against projected revenue increases resulting from faster production times could lead you toward making smarter decisions that align with both short-term cash flow concerns as well as long-term profitability goals.

Where to Purchase Laser Cutting Machines

Finding the right place to purchase a laser cutting machine can be as crucial as selecting the machine itself. With a myriad of options available, it’s essential to know where to look for quality and value. Whether you're seeking industry leaders, specialized offerings, or online marketplaces, there's a wealth of resources that can help you navigate the often complex landscape of laser cutting prices.

Industry Leaders in Laser Cutting

When it comes to laser cutting machines, several industry leaders set the standard for quality and innovation. Companies like Trumpf, Bystronic, and Amada are renowned for their advanced technology and robust performance in various applications. These manufacturers not only provide reliable machines but also offer comprehensive support services that can help mitigate some of the reasons why laser cutting is so expensive.

Investing in equipment from these established brands means you’re more likely to receive a machine with high resale value and excellent customer service. Additionally, they often have extensive networks for parts and maintenance that can save you money down the line—something crucial when considering overall laser cutting costs. So if you're asking yourself how much does laser cutting cost? Remember that choosing a reputable brand can significantly impact your investment's longevity.

Kiant Machinery’s Offerings

Kiant Machinery stands out as an emerging player in the laser cutting market with competitive pricing and versatile options tailored for different industries. They offer a range of machines suitable for both entry-level users and more advanced applications without compromising on quality or performance. Their focus on affordability makes them an attractive option if you're looking at various laser cutting machine prices.

Kiant Machinery also emphasizes customer education by providing training resources that help users maximize their investment—addressing one of the key factors contributing to why is laser cutting so expensive? By understanding how to operate these machines efficiently, businesses can lower their operating costs while improving productivity over time. If you’re eyeing 2025 Best Laser Cutting Machines lists, keep an eye on Kiant’s innovative offerings!

Online Marketplaces and Trade Shows

For those looking to explore various options without stepping foot outside their office—or even home—online marketplaces like Alibaba or eBay present numerous opportunities to find competitive prices on new or used laser cutting machines. These platforms allow buyers to compare models easily while also checking reviews from other users about reliability and performance before making a decision regarding which machine best fits their needs.

Trade shows are another excellent venue for discovering what’s hot in the world of laser technology while getting firsthand experience with different models before purchase decisions are made. Attending events like Fabtech or EuroBLECH offers invaluable insights into current trends, innovations, and even pricing strategies among competitors—perfect if you're trying to figure out how much does laser cutting cost? Plus, face-to-face interactions with suppliers can lead to better deals than what might be found online.

Why is Laser Cutting So Expensive?

When it comes to understanding laser cutting price, several factors play a pivotal role in determining just how much does laser cutting cost? The advanced technology behind laser cutting machines is a significant contributor to their overall expense. From sophisticated optics to high-performance lasers, the R&D costs associated with developing and refining these machines are substantial, leading to higher prices for consumers.

Advanced Technology and R&D Costs

The evolution of laser cutting technology has been nothing short of remarkable, but this innovation comes at a price. Manufacturers invest heavily in research and development to create more efficient, precise, and versatile machines. This investment not only raises the initial laser cutting machine price but also ensures that customers receive top-of-the-line equipment that can handle complex tasks with ease.

Additionally, as we look toward the future—specifically 2025's best laser cutting machines—the emphasis on integrating smart technologies like AI and IoT into these systems will further inflate costs. These advancements promise better performance and reliability but require ongoing investment from manufacturers. Thus, when considering how much does laser cutting cost?, it's essential to factor in these technological advancements that drive up the overall price tag.

Maintenance and Upkeep Expenses

Another reason why is laser cutting so expensive? Maintenance and upkeep expenses can be quite significant over time. Laser cutting machines require regular servicing to ensure they operate at peak efficiency; neglecting this can lead to costly repairs down the line. The intricate components of these machines need specialized care, which often translates into higher service fees or replacement parts.

Moreover, as manufacturers focus on producing more durable materials for their machines, the initial purchase may be steep—yet it could save you money in maintenance over time. However, it's crucial for potential buyers to budget not just for the initial laser cutting machine price but also for ongoing maintenance costs that can add up quickly if not managed properly.

Training and Support Services

Finally, another aspect contributing to why is laser cutting so expensive? The necessity for training and support services cannot be overlooked. Operating a sophisticated laser cutter requires skill; thus, many companies invest in training programs for their employees to maximize productivity while minimizing errors during operation.

Training programs often come with additional costs that should be factored into your overall budget when evaluating how much does laser cutting cost? Furthermore, many manufacturers offer ongoing support services that ensure your machine runs smoothly throughout its lifespan—adding yet another layer of expense but providing peace of mind as well. Ultimately, investing in quality training leads to better outcomes and long-term savings despite the initial higher costs associated with quality equipment.

Conclusion

In the world of manufacturing and fabrication, understanding laser cutting price is crucial for making informed investments. With various factors influencing the laser cutting machine price, it’s essential to evaluate your budget thoroughly. The decision to invest in a laser cutter can have long-lasting implications, both financially and operationally.

Evaluating Your Budget for Laser Cutting

When considering how much does laser cutting cost?, you need to account for not just the initial purchase but also ongoing expenses like maintenance and materials. A comprehensive budget should encompass all aspects of ownership, including labor costs associated with operating the machine. By taking a holistic view of your financial commitment, you'll be better positioned to choose a laser cutter that fits your needs without breaking the bank.

Long-Term Savings with Laser Cutting

Although the upfront laser cutting machine price may seem steep, it’s important to consider potential long-term savings that come with efficiency and precision. High-quality laser cutters can significantly reduce waste and improve production speed, leading to lower material costs over time. In essence, investing in one of the 2025 Best Laser Cutting Machines can yield substantial returns if managed wisely.

Making Informed Decisions on Laser Cutting Machines

Navigating through the myriad options available requires careful consideration of your unique needs and circumstances when evaluating why is laser cutting so expensive? Researching different models and their specifications will help you understand which features justify higher prices. Ultimately, making an informed decision based on thorough research will ensure you choose a machine that not only fits within your budget but also meets your production goals effectively.