Introduction

In the world of fabrication and construction, steel tube cutting is a critical process that demands precision and efficiency. Whether you're working on a large-scale project or a DIY home improvement task, understanding the various steel tube cutting techniques can make all the difference in achieving clean, accurate cuts. With an array of options available, selecting the right pipe cutter or metal cutting tool tailored to your specific needs is essential for optimal results.

Overview of Steel Tube Cutting Techniques

Steel tube cutting encompasses a variety of methods designed to slice through metal with ease and accuracy. Traditional techniques such as saws and torches have been around for decades, but modern advancements have introduced innovative solutions like laser cutting technology that revolutionize the process. Each technique has its strengths and weaknesses, making it crucial to understand which method aligns best with your project requirements.

Importance of Choosing the Right Tools

The importance of choosing the right tools for steel pipe cutting cannot be overstated; using inferior or inappropriate equipment can lead to poor results, wasted materials, and even safety hazards. Investing in high-quality metal cutting tools not only enhances efficiency but also ensures longevity and reliability throughout your projects.

What to Look for in a Pipe Cutter

First and foremost is the cutter's capacity; ensure it can handle the diameter and thickness of your specific pipes without straining its capabilities. Additionally, look for ergonomic designs that provide comfort during extended use as well as adjustable settings that allow for versatility across different applications.

Different Methods of Steel Tube Cutting

Whether you're a seasoned fabricator or a DIY enthusiast, understanding these methods will help you choose the best cutting tool for metal that meets your needs. From traditional manual tools to modern automated systems, the options are vast and can greatly influence the quality and efficiency of your work.

Overview of Common Techniques

Steel tube cutting encompasses several common techniques, including manual pipe cutters, band saws, plasma cutting, and laser cutting. Manual pipe cutters are often favored for their simplicity and precision in smaller projects. On the other hand, band saws and plasma cutters offer more versatility for larger or thicker pipes but require more skill and setup time.

In recent years, laser cutting has emerged as a frontrunner in steel tube cutting technology due to its speed and accuracy. Each method has its own set of characteristics that make it suitable for specific tasks; knowing these nuances is crucial when selecting the right pipe cutting tool for your project. Ultimately, choosing the most appropriate technique can save time and enhance overall results.

Comparing Traditional and Modern Methods

Traditional methods like manual pipe cutters have long been trusted for their reliability in various metalworking environments. They offer hands-on control that many craftsmen appreciate but can be labor-intensive and less efficient on larger scales. In contrast, modern methods such as CNC machines or laser cutters provide automation that significantly reduces human error while boosting productivity.

While traditional tools may require more physical effort, they often come at a lower initial cost compared to advanced machinery like laser systems or plasma cutters. However, investing in modern technology can lead to substantial long-term savings through faster processing times and reduced material waste—making them some of the best tools to cut steel pipe efficiently. The choice between traditional versus modern ultimately boils down to project requirements: scale versus precision.

Advantages of Each Technique

Each technique in steel tube cutting boasts unique advantages tailored to specific scenarios or user preferences. For instance, manual pipe cutters excel in portability; they’re easy to transport on job sites without requiring power sources—ideal for quick jobs or repairs where convenience is key. Meanwhile, machines like band saws provide clean cuts with minimal burrs on thicker materials—a significant advantage when aesthetics matter.

Modern methods like laser cutting stand out due to their unparalleled precision; they can achieve intricate designs with little post-processing needed—perfect for complex projects requiring high accuracy levels. Additionally, automated systems reduce labor costs over time by optimizing production speeds while maintaining consistent quality across multiple pieces—a game changer if you’re looking at large-scale operations! Ultimately, understanding these advantages helps you select not just any pipe cutter but truly the best tool for your specific metalworking needs.

Essential Metal Cutting Tools

Pipe cutting tools are specifically designed to handle the unique challenges presented by various types of metal pipes, ensuring precision and efficiency. Whether you're a seasoned professional or a DIY enthusiast, understanding these essential tools is key to successful projects.

Introduction to Pipe Cutting Tools

Pipe cutting tools come in various forms, each tailored for specific applications in steel tube cutting. From manual pipe cutters that offer portability and ease of use to more advanced machinery for industrial settings, there's a tool suited for every need. Choosing the right pipe cutter not only enhances your cutting experience but also extends the life of your tools and ensures safety during operation.

Best Tools for Steel Pipe Cutting

When selecting the best tool to cut steel pipe, consider factors such as material thickness, diameter, and project requirements. Some popular options include rotary pipe cutters that provide smooth cuts without excessive force and band saws that excel in handling larger volumes of materials efficiently. For those seeking precision in intricate designs, plasma cutters have emerged as one of the best cutting tools for metal due to their speed and accuracy.

How to Maintain Your Cutting Tools

Proper maintenance is crucial for prolonging the lifespan of your metal cutting tools and ensuring they perform at their best over time. Regularly cleaning your pipe cutting tool after use helps remove debris and prevents rust from forming on its surfaces; this simple step can significantly enhance its longevity. Additionally, sharpening blades when necessary will improve cutting efficiency—nobody enjoys struggling with dull edges when trying to achieve that perfect cut!

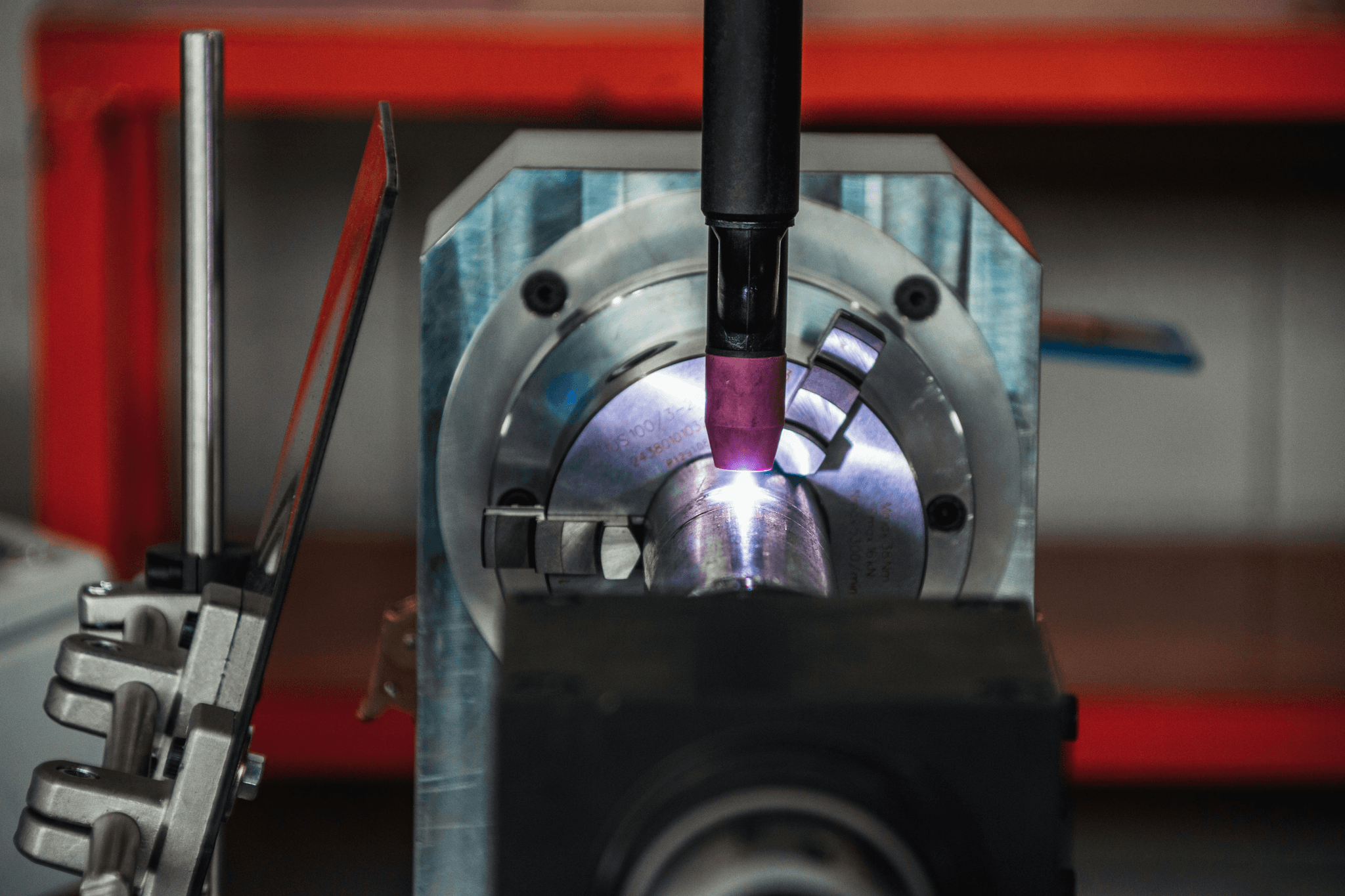

Laser Tube Cutting: A Game Changer

Laser tube cutting has revolutionized the steel tube cutting industry, offering unprecedented precision and efficiency. Unlike traditional methods that rely on mechanical tools, laser cutting uses focused beams of light to slice through materials with remarkable accuracy. This not only enhances the quality of cuts but also significantly reduces waste, making it an eco-friendly choice for metal fabrication.

Benefits of Laser Cutting Technology

One of the standout benefits of laser cutting technology is its ability to create intricate designs without compromising on speed or quality. The precision offered by a laser cutter ensures that even the most complex patterns can be executed flawlessly, making it an excellent choice for custom projects in steel pipe cutting. Additionally, laser technology minimizes heat-affected zones, which helps maintain the integrity of the material being cut—an essential factor when selecting the best tool to cut steel pipe.

Another advantage is versatility; laser tube cutters can handle various materials beyond just steel, including aluminum and stainless steel. This flexibility makes them one of the best cutting tools for metal available on the market today. Moreover, as technology advances, these machines are becoming increasingly user-friendly and cost-effective, appealing to both small workshops and large manufacturing facilities.

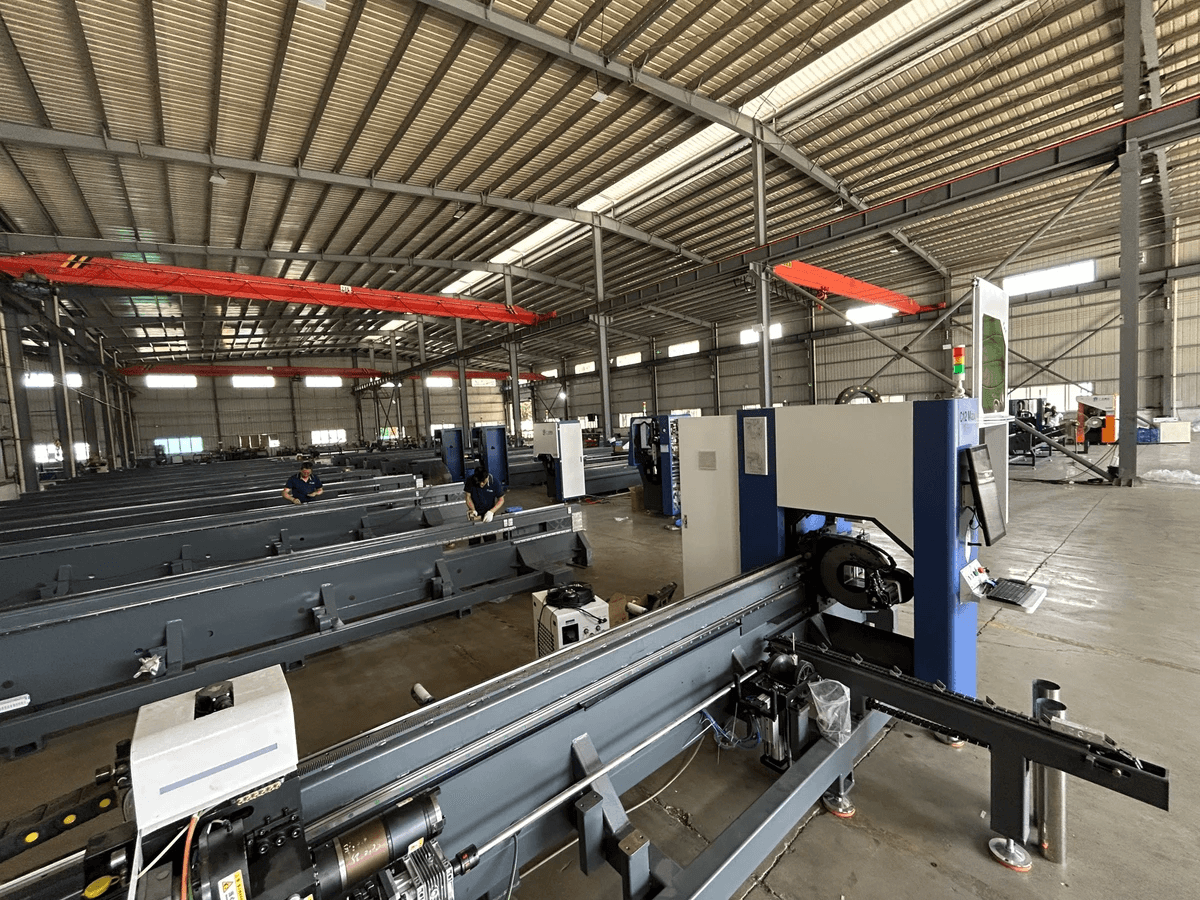

Kiant Machinery's Advanced Solutions

Kiant Machinery stands out in the realm of laser tube cutting with their innovative solutions designed specifically for metal fabricators. Their state-of-the-art machines combine speed with precision, ensuring that users can achieve high-quality cuts every time they operate their steel pipe cutter. With features like automatic loading systems and advanced software integration, Kiant Machinery simplifies what was once a complex process into a seamless operation.

What sets Kiant apart is their commitment to customer support and training; they provide extensive resources to ensure users maximize their investment in metal cutting tools. From initial setup guidance to ongoing maintenance tips for your pipe cutting tool, they cover all bases so you can focus on what matters—getting your job done efficiently and effectively. Plus, their machines are designed with durability in mind, ensuring longevity even under heavy use.

Real-World Applications of Laser Cutting

Laser tube cutting technology has found its way into various industries due to its unmatched capabilities in steel tube cutting. In automotive manufacturing, for instance, precision cuts are critical for creating components that fit together perfectly—something that traditional methods struggle to achieve consistently. Similarly, in construction and architecture sectors where design flexibility is key, laser-cut elements allow architects to push boundaries without sacrificing structural integrity.

Moreover, many artists have embraced this technology for creating intricate sculptures or decorative pieces from metal sheets or tubes—a testament to how versatile this method truly is! Even small businesses have begun utilizing these advanced solutions as they realize that investing in quality equipment like a steel pipe cutter can elevate their craftsmanship significantly while saving time and resources in production processes.

Choosing the Best Cutting Tool for Metal

With various types of pipe cutters and metal cutting tools available, it's essential to know what features will meet your specific needs. This section will guide you through the criteria for selecting the right tool, popular brands that offer reliable products, and a cost-benefit analysis to help you make an informed decision.

Criteria for Selecting the Right Tool

When choosing a pipe cutting tool for steel tube cutting, several criteria should be taken into account. First and foremost is the material compatibility; ensure that the cutter is designed specifically for steel pipes to avoid damaging both the tool and your workpiece. Next, consider the size of the pipes you'll be working with—some tools are better suited for larger diameters while others excel at precision cuts on smaller tubes.

Another important factor is ease of use; look for ergonomic designs that reduce fatigue during prolonged use. Additionally, assess whether you need a manual or powered option based on your workload and efficiency requirements. Ultimately, finding the best cutting tool for metal involves balancing performance features with your specific application needs.

Popular Brands and Their Offerings

In today’s market, several brands stand out when it comes to quality pipe cutters and metal cutting tools tailored for steel tube cutting. Brands like Ridgid and Milwaukee are renowned for their robust offerings in pipe cutting tools that combine durability with precision cuts. For those seeking advanced technology in their equipment, Bosch provides innovative solutions that enhance efficiency without sacrificing quality.

Other noteworthy brands include DeWalt and Makita, both known for their reliable performance in various metalworking applications including steel pipe cutters. Each brand offers unique features such as adjustable blades or integrated safety mechanisms which can significantly affect usability during projects. When considering which brand to choose, it's crucial to evaluate customer reviews and warranty options as well.

Cost-Benefit Analysis of Different Tools

Conducting a cost-benefit analysis is vital when selecting among various metal cutting tools available on the market today. Initially, it may seem tempting to opt for cheaper alternatives; however, investing in high-quality tools often leads to better long-term savings due to durability and reduced maintenance costs associated with premium models like those from established brands mentioned earlier.

Evaluate not only the upfront price but also factors such as replacement parts availability and potential downtime caused by equipment failure—these can add hidden costs over time if not considered upfront. Furthermore, consider how often you'll use these tools; if you're engaged in frequent steel tube cutting tasks or larger projects requiring precision cuts regularly, investing in a higher-end product may ultimately provide greater value.

Safety Considerations in Tube Cutting

When it comes to steel tube cutting, safety should always be the top priority. Using a pipe cutter or any metal cutting tools without proper precautions can lead to serious injuries. Therefore, investing time in understanding safety gear and practices is just as important as selecting the best cutting tool for metal.

Importance of Safety Gear

Wearing appropriate safety gear while using a steel pipe cutter is crucial for protecting yourself from potential hazards. At a minimum, this includes safety goggles to shield your eyes from flying debris and gloves to protect your hands from sharp edges. Additionally, sturdy footwear and hearing protection can prevent injuries during loud operations or if heavy materials are dropped.

Safety gear not only safeguards you but also enhances your focus on the task at hand, allowing you to operate your pipe cutting tool with greater confidence and efficiency. Remember that even the best tool to cut steel pipe won’t do you much good if you're not taking care of yourself first! Prioritizing personal protective equipment (PPE) can make all the difference in ensuring a safe working environment.

Common Hazards and How to Avoid Them

Steel tube cutting presents several hazards that should be recognized and mitigated before starting work. One common risk is exposure to sharp edges that can cause cuts or lacerations; using a steel pipe cutter with protective features helps minimize this danger. Additionally, improper handling of heavy pipes can lead to strains or crush injuries, so it's essential to use proper lifting techniques or mechanical aids whenever possible.

Another hazard arises from metal shavings and debris generated during cutting operations; these tiny particles can easily become airborne and injure your eyes or skin. Always ensure that you're wearing appropriate safety goggles and long sleeves when operating any metal cutting tools. By being aware of these risks and taking proactive measures, you significantly reduce the likelihood of accidents while using a pipe cutting tool.

Best Practices for Safe Operation

To ensure safe operation while engaging in steel tube cutting, following best practices is key. First off, always read the manufacturer's instructions for any equipment used—this includes understanding how to operate your pipe cutter correctly as well as knowing its limitations. Regularly inspect your tools for wear and tear before use; a malfunctioning tool not only affects performance but also poses serious risks.

Another vital practice is maintaining a clean workspace free of clutter that could cause trips or falls during operation—a tidy area allows you better focus on using your best cutting tool for metal effectively without distractions or hazards around you! Lastly, never rush through tasks; take your time when operating any equipment—after all, it's better to be safe than sorry when it comes down to handling potentially dangerous machinery like a steel pipe cutter.

Conclusion

In the world of steel tube cutting, choosing the right tools can make all the difference between a job well done and a frustrating experience. From traditional pipe cutters to advanced laser cutting technologies, each method has its own unique advantages tailored to specific needs. By understanding these effective cutting techniques, you can enhance your workflow and achieve precision in every cut.

Summary of Effective Cutting Techniques

Throughout this guide, we’ve explored various steel tube cutting methods, from manual pipe cutters to high-tech laser solutions. Each technique serves a purpose depending on material thickness, precision requirements, and project scale. Whether you opt for tried-and-true pipe cutting tools or modern innovations like laser technology, knowing their benefits allows you to choose the best cutting tool for metal that fits your needs.

Final Thoughts on Tool Selection

Selecting the right pipe cutter is crucial for efficiency and quality in metalworking projects. Consider factors such as material type, thickness, and desired finish when choosing your steel pipe cutter or any other pipe cutting tool. Investing in high-quality metal cutting tools not only improves your results but also ensures longevity and reliability throughout countless projects.

Future Trends in Steel Tube Cutting

As technology continues to evolve, so too will the methods and tools used for steel tube cutting. We can expect advancements in automation and precision engineering that will redefine what’s possible with metal fabrication. Staying informed about these trends will help you remain competitive and prepared for future demands in steel tube processing.